Product Details:

Payment & Shipping Terms:

|

| After-sales Service Provided: | Engineers Available To Service Machinery Overseas | Product Fineness: | 3 Micron - 150 Micron |

|---|---|---|---|

| Production Capacity: | 0.1 - 5 T/h | Construction Material:: | Carbon Steel/ Stainless Steel /ceramics |

| Process Engineering Service:: | Available | Drawing Software:: | 3D By Solidworks/ProE/Ug, 2D By AutoCAD |

| Automation And Control:: | PLC/ SCADA/ DCS |

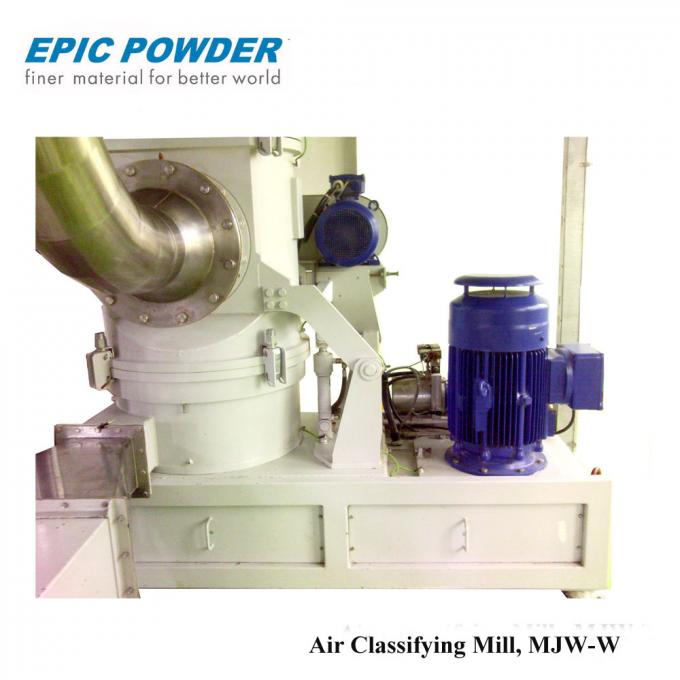

Ultra-fine Powder Mechanical Pulverizer High Quality Air Classifeir Grinding Mill

Air Classifier Mill, also called Air Classifying Mill and Dynamic Classifier Mill, represents one of the most universal milling

systems available. With its combination of an impact milling rotor and an integral dynamic classifier, each with independent variable speed drives, the MJW can process a variety of materials and produce a wide range of particle sizes. By simple adjustment of the classifier speed, the air classifier mill can make various cut points of 20 – 120 µm typically. Manufactured

in both carbon steel and 304/316L stainless steel, the classifier mill is used in all industries from chemicals and minerals to

food and pharmaceuticals.

For potentially explosive materials PSR11 (pressure shock resistant) mill design is available,

alternatively the mill system can be designed for pressure venting or nitrogen inerting. A special pharmaceutical design is

also available with fully enclosed motors and suitable for CIP.

The air classifier mill is made in a range of sizes from laboratory/pilot scale with 7.5kW mill drive motor

to production mills up to 250kW. Airflows are higher than standard pin mills or turbine mills, which has

the advantage of rapid heat dissipation and makes the DCM suitable for heat sensitive materials.

Material is fed into the air inlet bypass duct by an inverter controlled feeding device, and then

pneumatically conveyed into the classifier mill. On entering the mill, material is first presented to the

classifier and any “in spec” material passes directly through the classifier with the conveying air to the

product filter.

Coarse material rejected by the classifier falls into the grinding zone between the rotor hammers and

surrounding grinding track. Size reduction takes place until the particles are fine enough to be ‘picked

up’ by the mill internal airflow and are presented once again to the classifier. This internal recirculation

is repeated until the material is fine enough to pass through the classifier and exit the air classifier mill.

The product is separated from the conveying air in the filter. The product discharges through a rotary

valve and the clean air passes through the filter elements to the system fan and to atmosphere.

To ensure customer confidence in the capabilities of our equipment and processes, we operate a

comprehensive pilot plant in Qingdao city, China, which includes the Air Classifier Mill, where we can

run milling trials on your materials.

|

Activated carbon |

|

Baking mixes |

|

Barytes |

|

Carbon black |

|

Casein |

|

Crystalline cellulose |

|

Crystalline precipitates |

|

Food colourings |

|

General Chemicals |

|

Herbicides & Pesticides |

|

Iron Oxides |

|

Lactose |

|

Limestone |

|

Powder Coatings |

|

Resins |

|

Silica gels |

|

Sugar |

|

Vitamins |

|

Wheat gluten |

|

Zeolites |

|

Milk powder |

|

PCC & GCC |

|

Perlite |

|

Pharmaceutical API’s |

|

Pigments |

|

Chocolate crumb |

|

Cocoa |

1) What are our main products?

- We design and manufacture various powder grinding mills, classifiers, coating machines,

mixing machines, etc.

2) What service do we supply?

- We offer consultancy for project feasibility assessment, process flow definition,

preliminary layout and factory building plan, project budget, project time schedule,

etc.

- We supply sample processing tests in our test station where are equipped with our

various machine products, to help clients compare performances of different types

of machines or process.

- We supply project engineering, automation engineering and civil engineering.

- We send engineers to the clients’ project site and offer on-site technical instruction and

supervision during the machine installation, commissioning and test run.

3) How long time is our delivery?

- 60 to 90 days after the down payment received.

4) What payment terms do we offer?

- 30% by T/T as down payment;

- 70% by T/T before shipment or irrevocable L/C at sight.

5) What kind of shipment can we do?

- For complete machines, standard containers or frame containers by sea.

- For spare parts, wooden Case and pallet for delivery by air.

6) What service can we supply for machine installation and test run?

- We send engineers to the clients’ project site and offer on-site technical

instruction and supervision during the machine installation, commissioning

and test run.

7) What is our warranty policy?

- We offer lifetime service for our machine products after the delivery, and will

follow up the machine status with our clients after the successful machine

installation in our clients’ factories.

Kindly reminder, the price vary for different feed material and fineness a little.

for details, please contact our project consultants, thank you.

Contact Person: business