Product Details:

Payment & Shipping Terms:

|

| Condition: | New | Type: | Ball Mill & Classifying |

|---|---|---|---|

| Certification: | ISO, CE | Product Name: | Ball Mill |

| Max. Feeding Size: | Equal Or Less Than 20mm | Output Size: | 0.075-0.089 |

| Test: | Senior Professional Engineers Assigned | Installation: | Senior Professional Engineers Assigned |

| Color: | Customized | Weight: | Vary For Different Models |

| Model Number: | According To Different Models |

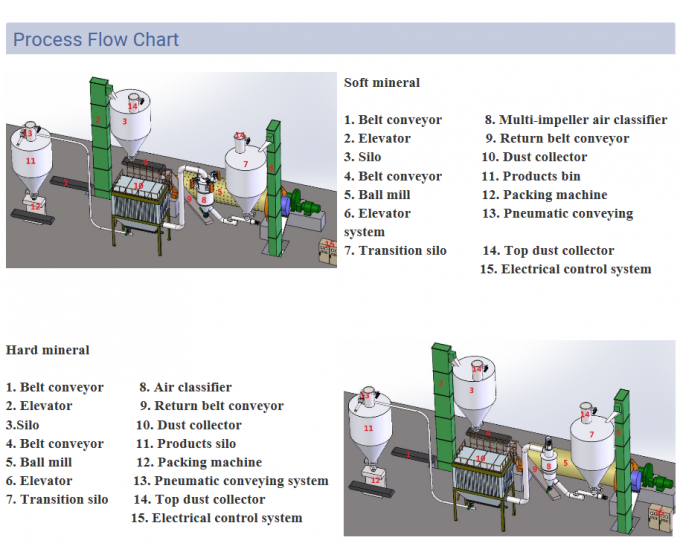

Ball mills is the key equipment for grinding after the crushing process. It is widly used in the processing of

cement, silicate, new building material,refractory material, fertilizer, ferrous and nonferrous metal,

glass as well ad ceramics. It is used to grind dry or wet ores and other materials of grindability.

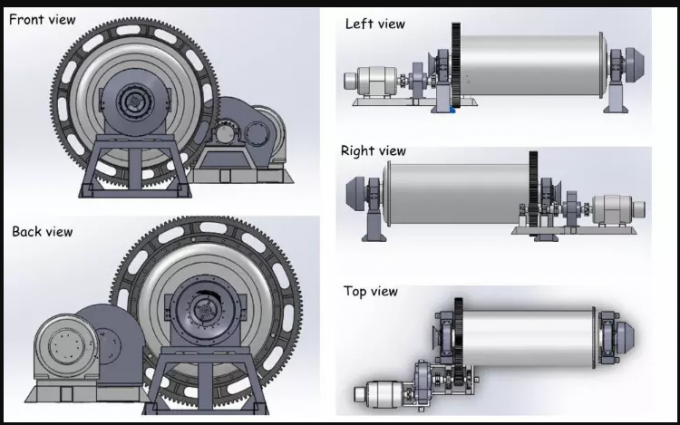

1. It is an efficient tool for grinding many materials into the powder.

2. The ball mill is used to grind many kinds of mine and other materials or to select the mine

3. Ball mill is widely used in buliding material and chemical industry.

4.There are tow ways of grinding: the dry way and the wet way.

5. Ball mill can be divided into tabular type and flowing type according to different expellingmine

6. To use the ball mill, the material to be ground is loaded into the neoprene barrel that contains

grinding media.

7. As the barrel rotates, the material is crushed betwwn the individual pieces of grinding media

that mix and crush the product into fine powder over a period of several hours.

8. The longer the ball mill runs, the finer the powder will be.

9. Ultimate particle size depends entirely on how hard the material you are grinding is, and the

thime how long the ball mill runs.

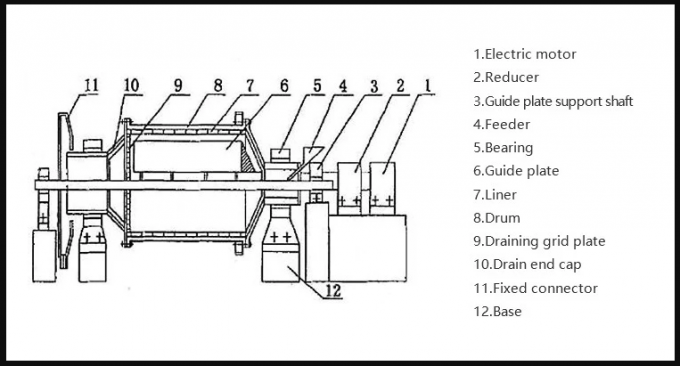

The materials are evenly conveyed to the first chamber through the feeding inside the first chamber, there are stepped or

ripple liners installed and different -sized steel balls placed. When the drum rotates, it gernerates centrifugal force, which

brings grinding balls to a certain height and then balls drop down, As a result, the materials are reduced in size by impact

and grinding.

After primary grinding in the first chamber, the materials goes into the second chamber through the single layer segregate

screen. In the second chamber, there are flat liners and grinding steel balls. Finally. the materials is discharged through the

grid plate.

Alumina,bauxite,calcium carbonate,kaolin,potassium feldspar,talc,fly ash,slag,zircon sand,cement,quartz,glass,etc.ication

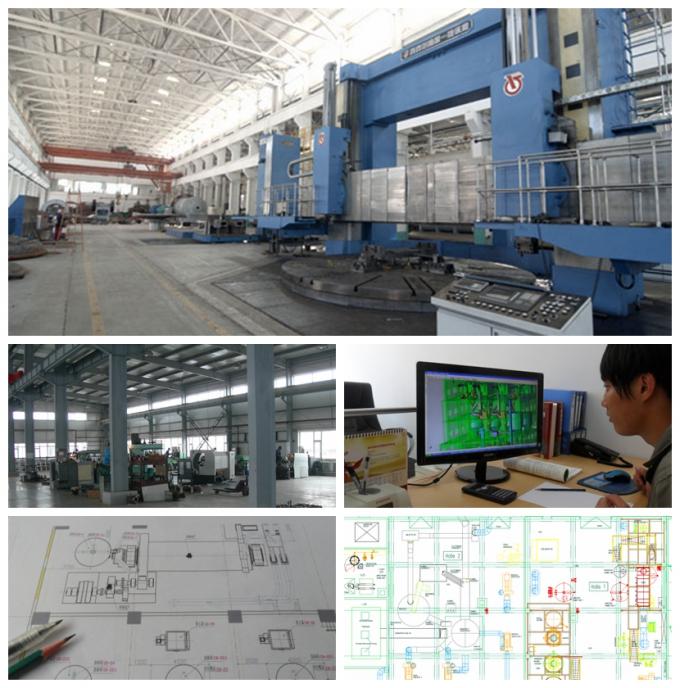

We EPIC POWDER is a professional supplier of fine powder processing projects, especially powder milling,

powder classifying, powder surface treatment and waste recycling, by dry process and wet process.

Our team has more than 35 years experience in various powders processing.

We have supplied machines and services to various fine powder processing projects in mineral industry,

chemical industry, food and agriculture industry, and pharmaceutical industry. We have a substantial test

database with over 5000 test reports of over 1000 different materials.

|

Pre-Sales Service

|

|

|

|

After-Sales Service

|

|

1.We shall offer equipment schedule,equipment layout,foundation drawing etc.

|

1) What are our main products?

- We design and manufacture various powder grinding mills, classifiers, coating machines, mixing machines, etc.

2) What service do we supply?

- We offer consultancy for project feasibility assessment, process flow definition, preliminary layout and factory

building plan, project budget, project time schedule, etc.

- We supply sample processing tests in our test station where are equipped with our various machine products,

to help clients compare performances of different types of machines or process.

- We supply project engineering, automation engineering and civil engineering.

- We send engineers to the clients’ project site and offer on-site technical instruction and supervision during the

machine installation, commissioning and test run.

- How long time is our delivery?

- 60 to 90 days after the down payment received.

3) What payment terms do we offer?

- 30% by T/T as down payment;

- 70% by T/T before shipment or irrevocable L/C at sight.

4) What kind of shipment can we do?

- For complete machines, standard containers or frame containers by sea.

- For spare parts, wooden Case and pallet for delivery by air.

5) What service can we supply for machine installation and test run?

- We send engineers to the clients’ project site and offer on-site technical instruction and supervision during the

machine installation, commissioning and test run.

6) What is our warranty policy?

- We offer warranty of 12 months after installation or 18 months after the delivery.

- We offer lifetime service for our machine products after the delivery, and will follow up the machine status with

our clients after the successful machine installation in our clients’ factories.

For details, please contact our project consultants, thank you.

Contact Person: business