| Place of Origin: | Shandong |

| Brand Name: | EPIC POWDER |

| Certification: | CE ISO |

| Model Number: | MQP |

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Steel Pallet & Wooden Case |

| Delivery Time: | 60 - 90 days after down payment received |

| Payment Terms: | L/C, T/T, D/P |

| Supply Ability: | 30 sets per quarter |

| Product Fineness: | D97: 2micron - D97: 45 Micron | Grinding Power Source: | High-pressure Compressed Air Flow |

|---|---|---|---|

| Grinding Temperature: | 20 Degree Celsius | Process Engineering Service: | Available |

| Civil Engineering Service: | Available | Drawing Software: | 3D By Solidworks/ProE/Ug, 2D By AutoCAD |

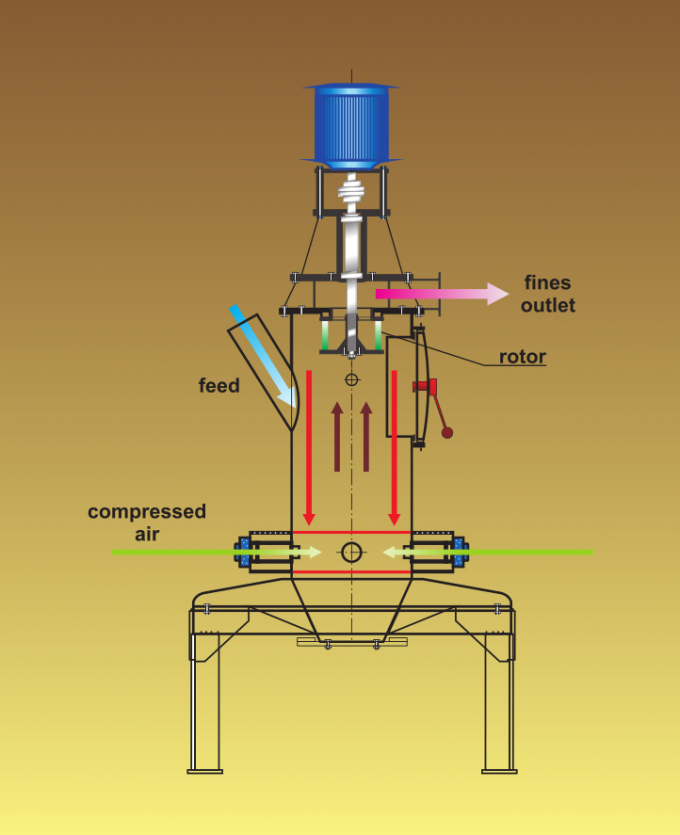

Micronizer Jet Mill is a pulverizing machine which uses high-speed compressed air to grind dry-type materials into ultrafine powders. It consists of screw feeder, milling nozzle, milling chamber, classifier chamber, and etc.

In adjustable speed, screw feeder doses the raw materials stably and continuously into the jet mill. Compressed air reaches a very high speed when rushing through the special designed nozzles. Carried by the compressed air, materials crash in the midst of air flow, where they grind with each other by impacting repeatedly. The ground materials fly upwards with the rising air, entering the classifier chamber, where ground materials facing two forces – the centrifugal force result from the fast rotation of classifier wheel and the pneumatic attraction by the suction fan. If the ground materials are finer than grading range, pneumatic attraction is stronger, so materials pass through the classifier wheel and move on to the cyclone and dust collector to be collected. In contrast, coarser materials are rejected back to the milling chamber to be re-milled.

Features:

| Simple, straightforward design with no moving parts |

| Engineered for easy dismantle and clean, easy access and maintenance |

| Efficient, effective one-step grinding and classifying operation |

| No heat from grinding |

| No media contamination |

| No lubricant contamination |

| Variety of available liners to prevent contamination and resist abrasion |

| Models for sanitary/ pharmaceutical applications available. |

Application:

- Abrasive products

- Sticky products

- Mineral fillers

- Ceramic fillers

- Food

- Chemical products

- Agricultural chemicals

Techincal Data:

Jet mill with vertical classifier.

| Model | MQL03 | MQL06 | MQL10 | MQL20 | MQL40 | MQL60 | MQL80 |

| Feed Size (mm) | <3 | <3 | <3 | <3 | <3 | <3 | <3 |

| Product Fineness (d97: μm) | 8-150 | 8-150 | 8-150 | 8-150 | 10-150 | 10-150 | 10-150 |

| Output (kg/h) | 5-100 | 10-200 | 20-400 | 50-800 | 150-1500 | 300-2000 | 400-6000 |

| Air Consumption (m³/min) | 3 | 6 | 10 | 20 | 40 | 60 | 80 |

| Air Pressure (Mpa) | 0.6-0.85 | 0.6-0.85 | 0.6-0.85 | 0.6-0.85 | 0.6-0.85 | 0.6-0.85 | 0.6-0.85 |

| Installation Powder (Kw) | 26-37 | 47-68 | 68-106 | 145-184 | 276-310 | 402-427 | 520-600 |

Note:

Data of production capacity and product fineness in this sheet are just for your reference. Due to the different characteristics of materials, one model of jet mill will give different production performance. Please contact me for tailored technical proposal or trials with your material.

1) What are our main products?

- We design and manufacture various powder grinding mills, classifiers, coating machines, mixing machines, etc.

2) What service do we supply?

- We offer consultancy for project feasibility assessment, process flow definition, preliminary layout and factory building plan, project budget, project time schedule, etc.

- We supply sample processing tests in our test station where are equipped with our various machine products, to help clients compare performances of different types of machines or process.

- We supply project engineering, automation engineering and civil engineering.

- We send engineers to the clients’ project site and offer on-site technical instruction and supervision during the machine installation, commissioning and test run.

3) How long time is our delivery?

- 60 to 90 days after the down payment received.

4) What payment terms do we offer?

- 30% by T/T as down payment;

- 70% by T/T before shipment or irrevocable L/C at sight.

5) What kind of shipment can we do?

- For complete machines, standard containers or frame containers by sea.

- For spare parts, wooden Case and pallet for delivery by air.

6) What service can we supply for machine installation and test run?

- We send engineers to the clients’ project site and offer on-site technical instruction and supervision during the machine installation, commissioning and test run.

7) What is our warranty policy?

- We offer warranty of 12 months after installation or 18 months after the delivery.

- We offer lifetime service for our machine products after the delivery, and will follow up the machine status with our clients after the successful machine installation in our clients’ factories.

For details, please contact our project consultants, thank you.

Contact Person: Crystal Ma