| Place of Origin: | Qingdao City, Shandong Province, China |

| Brand Name: | EPIC Powder |

| Certification: | CE, ISO |

| Model Number: | SRM 800, SRM 900, SRM 1000 |

| Minimum Order Quantity: | 1 unit |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Steel Pallet & Wooden Case |

| Delivery Time: | 60-90 days after payment |

| Payment Terms: | Western Union, L/C, D/P, T/T |

| Supply Ability: | 30 set per quarter |

| After-sales Service Provided: | Engineers Available To Service Machinery Overseas | Name: | Vertical Roller Grinding Mill In Mining Machinery For Sale |

|---|---|---|---|

| Product Fineness: | D97: 5 - 75 Micron | After-sale Service Term: | Lifetime Service |

| Automation: | PLC, HMI, Remote Computer Control | Process Engineering Service: | Available |

| Civil Engineering Service: | Available | Drawing Software: | 3D By Solidworks/ProE/Ug, 2D By AutoCAD |

| Delivery Time: | 60 - 90 Days After Down Payment Received | Place Of Origin: | China |

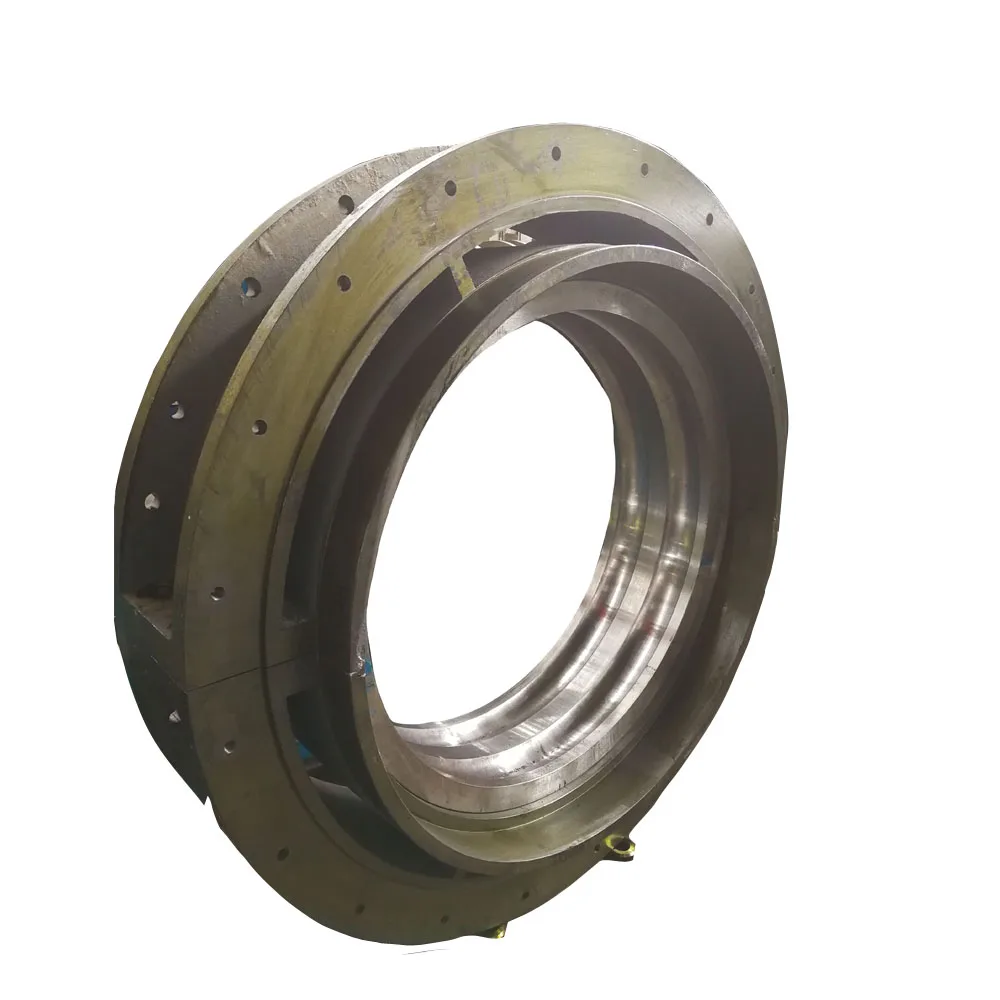

Grinding Fine Limestone Powder Roller Mill

Superfine roller mill is proven to be the most efficient dry grinding machine, if compared with traditional grinding machines like ball mill, impact mill, jet mill. It was designed to achieve lower energy consumption than ball mill for non-metallic mineral powder grinding in the beginning, and

now it has expanded its application to other industries like fine chemicals, construction material,

high-tech new material.

1. It is suitable for fine powder grinding of most materials of Mohs hardness less than 6.

2. It can make a wide range of product fineness, 200 mesh-2,500 mesh all possible.

3. Its integrated high-precision powder classifier on top guarantees good product fineness.

And the particle size distribution of its finished product is adjustable.

4. It requires low energy consumption than other types of grinding mills like ball mill, impact mill,

jet mill, in most cases.

5. It requires lower investment cost and smaller installation space than ball mill.

6. It is good for heavy-duty grinding and low maintenance. Hard-wearing material is selected for

key components like rollers and grinding track.

7. Its structure design is optimized for easy replacement of key components and minimum downtime.

8. Intelligent PLC control system makes sure simple operation and stable production.

|

Model |

Feed Size (mm) |

Moisture (%) |

Fineness (um) |

Capacity (t/h) |

Mill Motor (kW) |

|

SRM800 |

<10 |

<5 |

5 - 75 |

0.7 - 6 |

75 |

|

SRM900 |

<10 - 15 |

<5 |

5 - 75 |

1.4 - 12 |

110 |

|

SRM1000 |

<10 - 20 |

<5 |

5 - 75 |

2.1 - 18 |

132 - 160 |

- calcium carbonate (limestone, marble, chalk)

- dolomite

- gypsum

- talc

- barite

- petrol coke

- battery material

- activated carbon

- carbon black from pyrolyzed waste tire

Contact Person: business