| Place of Origin: | Qingdao City, Shandong Province, China |

| Brand Name: | EPIC Powder |

| Certification: | ISO, CE |

| Model Number: | ITC, HTS |

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Steel Pallet & Wooden Case. |

| Delivery Time: | 60-90 days |

| Payment Terms: | L/C, T/T, D/P |

| Supply Ability: | 30 sets/quarter |

| After-sales Service Provided: | Engineers Available To Service Machinery Overseas | Product Fineness: | D97: 3 - 150 Micron |

|---|---|---|---|

| Civil Engineering Service: | Available | Drawing Software: | 3D By Solidworks/ProE/Ug, 2D By AutoCAD |

| Installation: | Engineer Instruction And Supervision On Site | After-sale Service Term: | Lifetime Service |

| Automation And Control: | PLC/ SCADA/ DCS | Weight: | Different |

| Powder: | 45-132 Kw | Capacity: | 1-30 T/H |

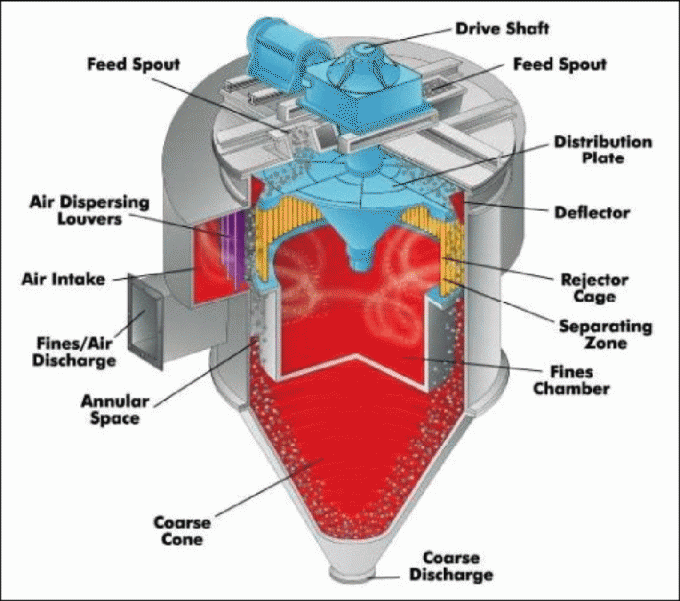

Comparing to traditional separators, ITC separator demonstrates prominent advantages as follows:

1. It separates material into “three parts”: coarse powder , medium powder and fine powder. Coarse

powder returns to cell 1 of the grinder, powder from the medium cell is delivered to the grinding cell (or

entering cell 1 with coarse powder), and fine powder is in-warehouse directly as finished product.

2. Comparing to centrifugal, cyclone or rotor separator with similar size, ITC separator achieves much

higher output and better adapts to mass production.

3. Stepless speed adjustment style spindle. Easy, flexible and reliable fineness regulation and wide

regulation scope.

4. Spaces at separation and lifting zones are re-optimized and re-designed to increase material/gas

ratio and improve separation efficiency by making full use of main space.

5. New design is employed to sealing of the lower bearing of spindle, addressing bearingdust and

lubricant leakage issues effectively and actually extending service life of the lower bearing.

Process

This air classifeir series has been developed especially for ultra fine cut points. The main point of

its development was to achieve a high fineness of the end product. A good sharpness, high efficiency

and low specific engrgy consumption with highest fines output were the guide line for this target.

We could achieve these criteria by optimizing the dynamic of air flow, the material resistance and

the multi - wheel concept.

1) What are our main products?

- We design and manufacture various powder grinding mills, classifiers, coating machines,

mixing machines, etc.

2) What service do we supply?

- We offer consultancy for project feasibility assessment, process flow definition, preliminary

layout and factory building plan, project budget, project time schedule, etc.

- We supply sample processing tests in our test station where are equipped with our various

machine products, to help clients compare performances of different types of machines or process.

- We supply project engineering, automation engineering and civil engineering.

- We send engineers to the clients’ project site and offer on-site technical instruction and

supervision during the machine installation, commissioning and test run.

3) How long time is our delivery?

- 60 to 90 days after the down payment received.

4) What payment terms do we offer?

- 30% by T/T as down payment;

- 70% by T/T before shipment or irrevocable L/C at sight.

5) What kind of shipment can we do?

- For complete machines, standard containers or frame containers by sea.

- For spare parts, wooden Case and pallet for delivery by air.

6) What service can we supply for machine installation and test run?

- We send engineers to the clients’ project site and offer on-site technical instruction and

supervision during the machine installation, commissioning and test run.

7) What is our warranty policy?

- We offer warranty of 12 months after installation or 18 months after the delivery.

- We offer lifetime service for our machine products after the delivery, and will follow up the

machine status with our clients after the successful machine installation in our clients’ factories.

For details, please contact our project consultants, thank you.

Noted: Due to the machine are customized, So the price will vary depending on the raw materials,

product fineness and production rate, etc.

Contact Person: business