Drying & Dispersing

For many products in our daily life requires grinding process. From breakfast cereals to cold medicine to paint and cement, grinding is a key step in bringing products to the market in the right form.

When the material enters machine, it is milled at high speed, which increases the evaporation surface area, has a large drying capacity, significant energy saving, high thermal efficiency of more than 70%.

The quality of dried products is uniform, the maximum dehydration capacity can reach 2t/h, product modification can also be carried out at the same time.

Negative pressure, dust-free, operation is simple, maintenance cost is low, variety of automatic protection functions and high reliability.

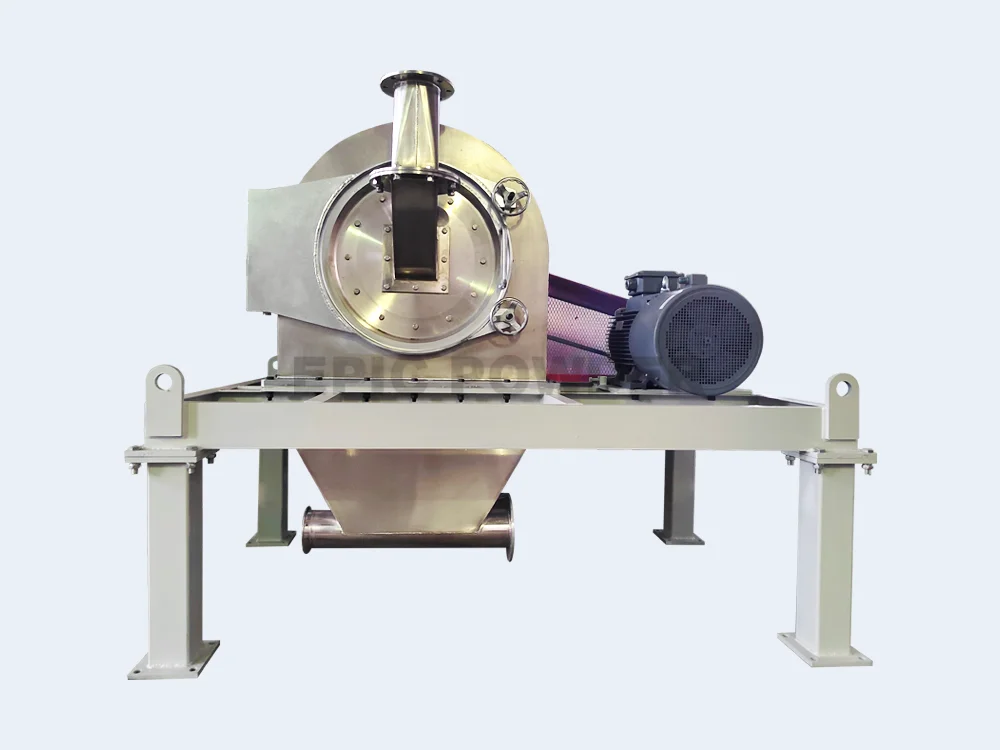

Rotor Mill for drying, dispersing and modifying

Industry we serve

Send Us A Message

info@epic-powder.com

PHONE

+86 15762272120 Mon to Fri 08:00 am – 6:00 pm

LOCATION

NO. 369, Road S209, Huanxiu, Qingdao City, 266201, Shandong Province, CHINA