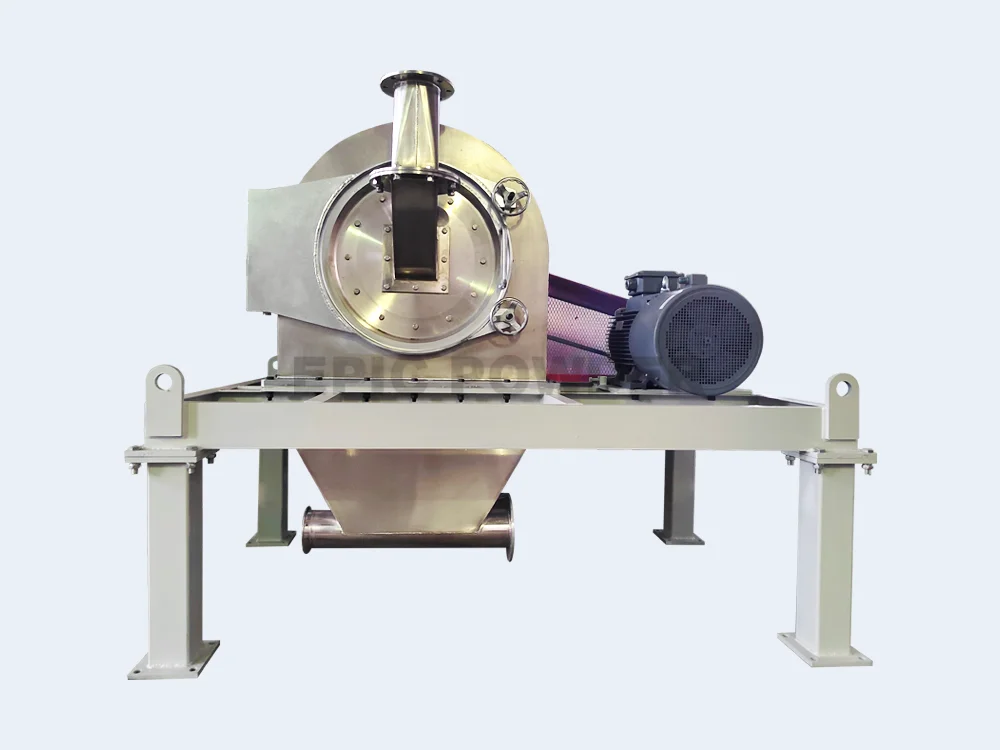

Vibration Mill

A vibration mill is a size reduction equipment that applies the process of continuous impaction in carrying out its size reduction function. The grinding container is made up of a tube that is held in a frame that is supported by means of springs which is filled to approximately 80% total volume with porcelain or stainless steel balls.

Working Principle

With the high-speed vibrator or vibration motor, the grinding media (pins, cylpebs or balls) would vibrate in high frequency, high-speed rotating and slow revolving, which would impact, rub and shear materials around them and make them into fine powder and mix them evenly.

During milling, the entire body of the mill undergoes a small but frequent vibration that is generated by an eccentric motor, and size reduction occurs by repeated impact. This vibration is usually, but not necessarily, in a vertical plane.

Vibration mills are similar to ball mills in that particles of the materials are crushed between porcelain or metal balls and the mill body.

Drugs and excipients are readily ground to less than 5 μm, the grinding time being considerably less than is required in normal ball milling. As a result, the efficiency of the comminution process in vibratory milling is a good deal than it is in conventional ball milling.

Features And Benefits

- Suitable for hard abrasive grinding stocks

- Unlike tumbling mills, the porcelain in the vibrating mills move only a few millimeters through a complex path, shearing and impacting the materials between them.

- Higher grinding rate in the range of fine particles.

- Suitable for grinding raw materials with Moh’s hardness below 9.

- Particle size can be adjustable by adjusting parameters such as grinding medium, amplitude, and frequency. The finer powder can be given in conjunction with classifier in series.

- Grinding media and liners can be made of special materials such as high manganese steel, high chromium steel, stainless steel, alumina, zirconia, quartz, etc., which are wear resistant and less pollution.

- Not suitable for thermolabile material

Technical Parameters

| Parameter / Model | ZM03 | ZM10 | ZM50 | ZM100 | ZM200 | ZM300 | ZM450 | ZM600 |

|---|---|---|---|---|---|---|---|---|

| Volume(L) | 3 | 10 | 50 | 100 | 200 | 300 | 450 | 600 |

| Motor power(kW) | 0.37 | 1.5 | 7.5 | 15 | 30 | 45 | 55 | 75 |

| Amplitude(mm) | 4 | 5 | 9 | 9 | 9 | 9 | 9 | 9 |

| Fineness(mesh) | 50-2500 | 50-2500 | 50-2500 | 50-2500 | 50-2500 | 50-2500 | 50-2500 | 50-2500 |

Related Products

Technical Parameters

Related Posts

Send Us A Message

info@epic-powder.com

PHONE

+86 15762272120 Mon to Fri 08:00 am – 6:00 pm

LOCATION

NO. 369, Road S209, Huanxiu, Qingdao City, 266201, Shandong Province, CHINA