Chemical

The chemical industry occupies an important position in the national economy of various countries, and is the basic industry and pillar industry of many countries. The development speed and scale of the chemical industry have a direct impact on all sectors of the social economy. The annual output value of chemical products in the world has exceeded US$1.5 trillion.

Chemical substances are everywhere in our daily lives and can be seen everywhere. Printer toners, kitchen PTFE coated frying pans, resins, flame retardants, cellulose, pesticides, etc. are all products of the fine chemical industry.

After 20 years of continuous research and exploration, EPIC Powder has more advanced technical experience in grinding, crushing and grading of high-quality coatings, pigments, printing inks, high-performance ceramics, adhesives, and sealants. Using ultra-fine powder technology, the raw materials are easily processed, and the crushing size of the material particles is from 2mm to 2μm, which greatly improves the utilization rate of materials and promotes the transformation of the chemical industry.

Project Cases

Related Posts

We can provide processes and equipment that meet the following performance indicators

Jet Mill

Suitable for grinding materials with high hardness, high purity and high added value.

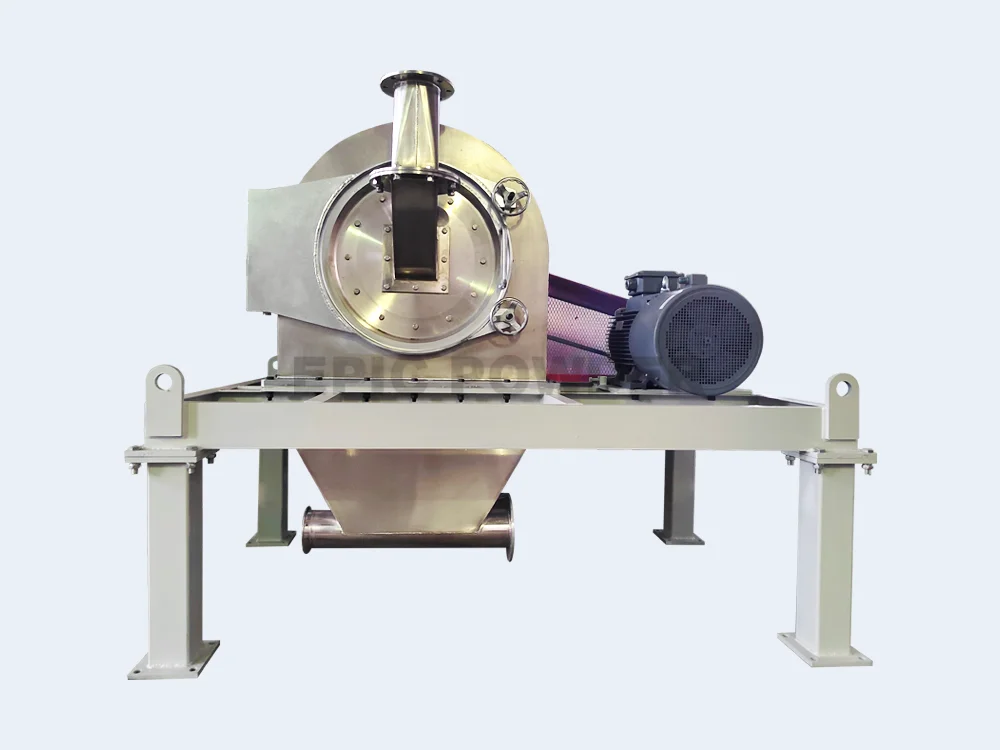

Air Classifying Mill

Integration of grinding and classifying

Air Classifier

Realize the separation of particles of different sizes

Pin Mill

The material should not exceed Mohs hardness 3.

Ball Mill and Air Classifier Production Line

Cooperate with the classifier to produce products of multiple particle sizes at the same time

- According to the material hazard and explosion-proof level, adopt comprehensive safety fire-fighting measures such as explosion venting, explosion isolation, and explosion suppression to ensure safe and controllable production and operation.

- According to the temperature requirements of the material production process, air-cooled, water-cooled, liquid nitrogen and other targeted temperature control measures are adopted to keep the material at an appropriate temperature during the production process.

- The closed-loop process design of air or inert gas circulation is adopted to effectively control the intake of external moisture.

- The key parts in contact with the materials are protected by a variety of materials to ensure the purity of the materials to a greater extent.

- Adopt the integrated solution of drying and crushing, shorten the process flow, save the workshop space, and greatly reduce the unit energy consumption and equipment investment.