Discover what a jet mill is and how it works to achieve ultra-fine particle size reduction using high-velocity gas jets for precise micronization.

The Basics What Exactly Is a Jet Mill Core Definition and Historical Evolution

A jet mill is a specialized machine designed for ultra-fine grinding and particle size reduction using high-velocity air or gas streams. Unlike traditional mills, jet mills operate without moving parts inside the grinding chamber. Instead, they use the energy of compressed air or gas to accelerate particles and make them collide with each other. This process, called micronization, produces very fine powders with high purity and uniform sizes.

The concept of jet milling dates back several decades and evolved alongside advances in compressed air technology. Early models focused on grinding heat-sensitive materials that could not withstand conventional milling methods. Over time, improvements led to different types of jet mills like spiral jet mills and fluidized bed jet mills, each optimized for specific applications.

Today, jet mills are widely used in industries such as pharmaceuticals, chemicals, and food processing because they efficiently produce ultra-fine powders without contamination or heat damage. Their core principle of inter-particle collision combined with no moving parts makes them a reliable and clean option for delicate materials.

The Basics What Exactly Is a Jet Mill Key Components of a Jet Mill System

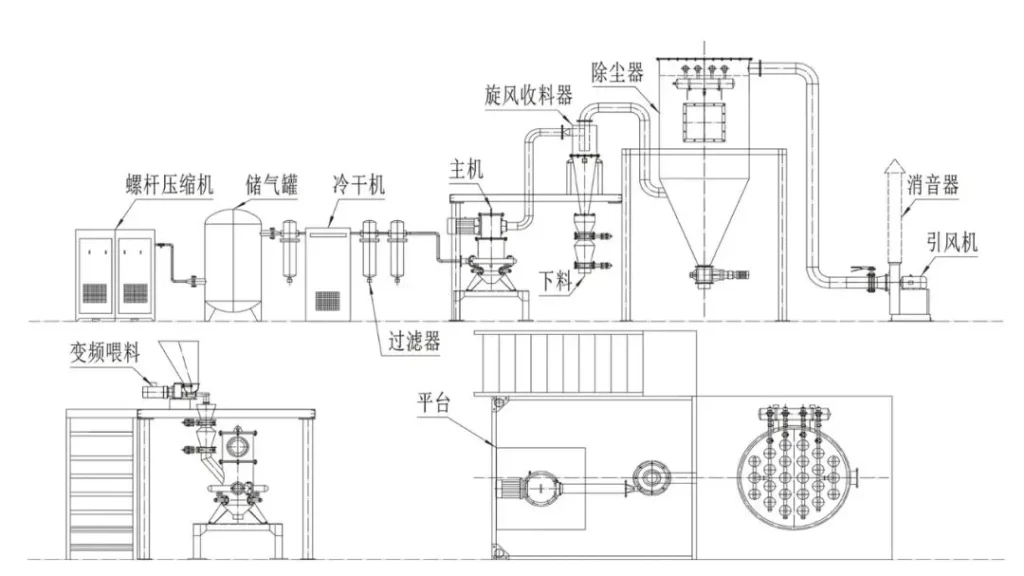

A jet mill system is made up of a few important parts working together to grind materials into ultra-fine powders. At the heart of the system, you’ll find the nozzle assembly, where compressed air or gas is blasted at high speeds. This high-pressure air is key to the jet mill’s micronization process and particle size reduction.

Next is the grinding chamber, a special space where particles collide with each other at high speeds—this is called inter-particle collision. Unlike traditional mills, jet mills have no moving parts milling inside, which means less wear and tear, and less heat generated during grinding.

There’s also a classifier, often built-in or attached, that separates the finely ground powder from the coarser particles, ensuring uniform particle size. Some jet mills use a fluidized bed jet mill design to improve air circulation and grinding efficiency, while others might use a spiral jet mill setup for different milling needs.

Together, these components enable precise control over powder quality, making jet mills a favorite for handling heat-sensitive materials grinding and producing pure, consistent powders for industries like pharmaceuticals and specialty chemicals.

The Basics What Exactly Is a Jet Mill Types of Jet Mills for Different Needs

Jet mills come in a few main types, each designed to fit specific grinding needs. The most common ones are spiral jet mills and fluidized bed jet mills.

Spiral Jet Mills use high-speed air jets that swirl in a spiral pattern inside the chamber. This swirl creates intense collisions between particles, efficiently breaking them down into ultra-fine powders. They’re great for tough, hard materials and allow precise control over particle size.

Fluidized Bed Jet Mills work by suspending the particles in an upward airflow, creating a “fluidized” state. This keeps particles separated and leads to gentler grinding. These mills are often preferred for heat-sensitive materials like pharmaceuticals because they generate less heat during the milling process.

Depending on what you need—whether it’s super fine micronization for pharmaceuticals or bulk powder classification for chemicals—there’s a jet mill type that fits. Choosing the right style helps maximize efficiency and product quality while handling different materials safely.

How Does a Jet Mill Work Step-by-Step Breakdown The Fundamental Working Principle

At its core, a jet mill uses high-speed jets of compressed air or gas to grind materials into ultra-fine particles. Unlike traditional mills with moving parts, a jet mill relies on the force of these jets to make particles collide with each other inside the grinding chamber. This process, called inter-particle collision, breaks the materials down into much smaller sizes.

The high velocity of the gas creates a fluidized bed where particles float and clash continuously, which helps achieve consistent particle size reduction without friction from mechanical parts. Because the energy comes from air or gas streams, no heat builds up during milling, making jet mills perfect for heat-sensitive materials like pharmaceuticals.

This method also allows for precise control over grinding by adjusting gas pressure and feed rate, resulting in highly uniform powders through the micronization process. Key jet mills, including spiral jet mills and fluidized bed jet mills, operate on this same working principle but differ in design to fit specific material and size requirements.

How Does a Jet Mill Work Step-by-Step Breakdown The Milling Process in Action

In a jet mill, the actual milling happens when high-speed jets of compressed air or gas collide inside the grinding chamber. Here’s what goes down during the milling process:

- Material Feeding: Powder or granules are introduced into the mill through a feed valve or hopper.

- Acceleration: Once inside, the particles are caught in high-velocity air jets that speed them up to nearly the speed of sound.

- Inter-particle Collision: These fast-moving particles smash into each other, breaking down into smaller, ultra-fine pieces. Unlike traditional mills, there are no moving parts inside — it’s all about the power of particle-to-particle impact.

- Grinding Zone: The grinding chamber is designed to keep particles suspended and continuously colliding until they reach the desired size.

- Powder Classification: After milling, an integrated classifier separates fine particles from coarse ones. The coarse particles continue circulating in the chamber until they’re finely ground.

- Product Collection: Finally, the finely ground powder is collected and ready for use.

This process makes jet mills perfect for ultra-fine grinding and micronization, especially useful when working with heat-sensitive materials since no mechanical parts generate unwanted heat.

How Does a Jet Mill Work Step-by-Step Breakdown Energy Dynamics Why No Heat Buildup

One standout feature of jet milling is that it doesn’t generate much heat during the grinding process. That’s a big deal, especially when you’re working with heat-sensitive materials like certain pharmaceuticals or fine chemicals.

Here’s why this happens: a jet mill uses high-speed compressed air or gas to accelerate particles inside the grinding chamber. These particles collide with each other at high velocity, breaking down into smaller sizes. Since there are no moving mechanical parts like blades or wheels rubbing against the material, there’s minimal friction, which means very little heat is produced.

Also, the air used to power the jet mill acts like a coolant, quickly carrying away any tiny heat generated. This keeps the overall temperature low, preventing damage or changes to the material’s properties.

In short, the combination of inter-particle collision and the constant air flow ensures efficient micronization without overheating—making jet mills perfect for materials that would degrade under traditional grinding methods.

Advantages of Jet Milling Why Choose It Over Traditional Methods Superior Particle Quality and Purity

One of the biggest reasons to choose jet milling over traditional grinding methods is the superior particle quality and purity it delivers. Because jet mills use high-speed air or gas streams to grind materials, there’s no metal-to-metal contact, which means no contamination from grinding parts. This is especially important for industries like pharmaceuticals and food, where purity is critical.

Jet milling also produces very uniform, ultra-fine particles thanks to its precise particle size reduction and powder classification. The micronization process here ensures tight control over particle size distribution, giving you a consistent product every time. Plus, this no moving parts milling approach minimizes heat buildup, protecting heat-sensitive materials from degradation. This level of quality isn’t as easy to achieve with traditional mills, which often introduce more heat and contaminants into the process.

Advantages of Jet Milling Why Choose It Over Traditional Methods Efficiency and Versatility

Jet mills stand out when it comes to both efficiency and versatility in the particle size reduction world. They use high-speed air or gas streams to grind materials without any moving parts, which means less wear and tear and lower maintenance compared to traditional mills. This design also allows for continuous operation, making jet mills great for high-volume production.

One big advantage is their ability to handle a wide range of materials—from hard minerals to heat-sensitive substances like pharmaceuticals—without changing the machine setup. You can easily switch between grinding different materials without cross-contamination thanks to the clean, no-contact milling environment. Plus, jet mills deliver consistent ultra-fine grinding or micronization, producing uniform particles as small as a few microns.

This versatility extends beyond just the material variety. Jet mills can be customized with different types like spiral jet mills or fluidized bed jet mills to fit specific milling needs, from dry powder classification to ultra-fine grinding. This flexibility combined with efficient energy use makes jet milling a smart choice for U.S. manufacturers looking to optimize production quality and cost.

Key efficiency and versatility highlights:

- No moving parts mean lower maintenance and downtime

- Continuous operation for large-scale production

- Handles heat-sensitive and abrasive materials without degradation

- Easy switching between materials to avoid contamination

- Adjustable for micronization and precise particle size control

- Suitable for diverse industries including pharmaceuticals, chemicals, and food sectors

Overall, jet milling delivers a reliable, adaptable milling solution that meets the demanding needs of modern U.S. manufacturing setups.

Advantages of Jet Milling Why Choose It Over Traditional Methods Limitations to Consider

While jet milling offers many benefits like ultra-fine grinding and no heat buildup, it’s not perfect for every situation. Here are some limitations to keep in mind:

- High Energy ConsumptionJet mills use compressed air or gas, which can lead to higher energy costs compared to some traditional milling methods.

- Not Ideal for Very Hard MaterialsExtremely tough or abrasive materials may wear out the mill components faster, increasing maintenance needs.

- Lower Throughput for Some ApplicationsBecause the process focuses on fine particle size reduction, it might be slower than coarse grinding methods if you need large quantities fast.

- Requires Clean, Dry Feed MaterialMoist or sticky feeds can cause clogging or affect performance, so proper material prep is essential.

- Initial Investment CostsJet mills, especially advanced types like spiral or fluidized bed jet mills, may have a higher upfront cost than simpler grinders.

Despite these limitations, for tasks requiring precise particle size reduction, especially with heat-sensitive materials or pharmaceutical jet milling, jet mills remain a go-to choice in the U.S. market. Understanding these factors helps you decide if jet milling fits your production needs.

Real-World Applications Where Jet Mills Shine Industry Spotlights

Jet mills are widely used across industries that require ultra-fine grinding and precise particle size reduction. Here’s where they truly stand out:

- Pharmaceuticals: Jet milling is essential for grinding heat-sensitive materials like drugs without causing degradation. It ensures uniform particle size, which improves drug bioavailability and consistency.

- Chemical Industry: Chemicals often need to be micronized for better reaction rates or improved product performance. Jet mills handle abrasive and reactive powders safely and efficiently.

- Food and Beverage: Powdered ingredients such as spices, sugars, and flavorings benefit from jet milling’s ability to create fine, consistent powders without exposure to heat that could alter taste or quality.

- Cosmetics: The beauty industry relies on smooth, ultra-fine powders for products like face powders and foundations. Jet mills help achieve that soft texture with high purity.

- Minerals and Metals: In mining and metallurgy, jet mills grind minerals into fine powders used in various applications, from ceramics to metal coatings.

- Electronics: Materials like titanium dioxide and other compounds used in electronics need precise particle size control, which jet milling delivers efficiently.

Thanks to no moving parts milling and inter-particle collision mechanisms, jet mills offer a clean, efficient way to process materials that can be sensitive or require precise powder classification. This makes them a top choice across diverse US industries focused on quality and performance.

Real-World Applications Where Jet Mills Shine EPIC Powder Machinery Solutions

At EPIC Powder Machinery, we understand the unique demands of jet milling across industries in the United States. Our jet mill solutions are designed to handle everything from pharmaceuticals to specialty chemicals with precision and reliability. Whether you’re working with heat-sensitive materials or need ultra-fine grinding for micronization processes, our equipment consistently delivers superior particle size reduction without contamination.

We offer a range of jet mills, including spiral jet mills and fluidized bed jet mills, tailored to your specific needs. Our team focuses on optimizing your milling setup to ensure maximum efficiency and product purity. Plus, with no moving parts in many of our jet mill designs, maintenance is straightforward and downtime is minimized—keeping your operations running smoothly.

For industries requiring powder classification or processing of delicate materials, EPIC Powder Machinery provides expert advice and customized solutions to get you the best results from your jet milling process. Trust EPIC to bring advanced grinding technology right to your doorstep, helping local manufacturers and processors stay competitive with top-quality powders.

Jet Mill vs Other Grinding Technologies A Quick Comparison

When it comes to grinding and particle size reduction, jet mills stand out, but how do they stack up against other common grinding methods?

Jet Mill Advantages:

- Ultra-fine Grinding: Jet mills can grind particles down to the micron or even sub-micron level, which many traditional grinders can’t achieve.

- No Moving Parts: Since jet mills use high-speed air streams to grind, there’s less wear and tear compared to ball mills or hammer mills.

- No Heat Buildup: Because the grinding happens through inter-particle collision and the process uses compressed air, heat-sensitive materials won’t degrade—a big plus for pharmaceutical jet milling.

- Consistent Particle Size: Powder classification inside the mill ensures a uniform particle size distribution.

Other Grinding Technologies:

- Ball Mills: Great for coarse to fine particle size but can generate heat and contamination due to friction and moving parts.

- Hammer Mills: Better suited for breaking down larger particles quickly but often lack the precision of a jet mill.

- Spiral Jet Mills and Fluidized Bed Jet Mills: These are variations of jet mills optimized for specific materials or fine-tuning particle shapes, but they share the same basic advantages.

Drawbacks to Consider:

- Jet mills generally require higher initial investment and operational costs because compressed air use can be energy-intensive.

- For coarser grinding, traditional mills might be more cost-effective.

In short, if you need ultra-fine, pure powders, especially for heat-sensitive materials, a jet mill is hard to beat. For tougher, larger particle breakdowns, other grinding technologies might do the job more economically.

Optimizing Your Jet Milling Setup Tips from EPIC Experts Material Selection and Prep

Getting the best out of your jet mill starts with choosing the right material and preparing it properly. At EPIC Powder Machinery, we’ve seen firsthand how careful material selection and prep can make a huge difference in performance.

Material Selection Tips:

- Consider hardness and abrasiveness: Softer, friable materials like pharmaceuticals and food powders work great. Harder or abrasive materials may wear parts faster.

- Check moisture content: Too much moisture can cause clumping and reduce milling efficiency. Dry materials typically grind better.

- Look at particle size before milling: Starting with smaller particles helps achieve ultra-fine grinding faster.

Preparation Steps:

- Pre-screen or sieve materials: Remove large chunks or contaminants to avoid damaging the mill or affecting powder quality.

- Dry materials thoroughly: Use drying methods suitable for heat-sensitive materials to keep quality intact.

- Control feed rate: Feeding material steadily and evenly helps avoid overloading and ensures consistent micronization.

Following these tips ensures smoother operation and better particle size reduction, whether you’re running a spiral jet mill or a fluidized bed jet mill. For more details, check EPIC’s full guide on optimizing jet milling setups.

Optimizing Your Jet Milling Setup Tips from EPIC Experts Scaling and Maintenance Best Practices

Scaling your jet milling operations smoothly means paying close attention to both equipment and process. Here are key tips from EPIC Powder Machinery to keep things running efficiently:

Start Small and Test

- Begin with pilot runs to dial in your particle size and feed rate.

- Use these tests to identify potential issues before scaling up.

Maintain Consistent Feed Quality

- Pre-screen materials to avoid clogs or uneven grinding.

- Keep moisture levels steady—jet mills handle dry powders best.

Regular Cleaning and Inspection

- Clean the milling chamber frequently to prevent buildup.

- Check nozzles and classifiers for wear—worn parts reduce efficiency and affect particle size.

Monitor Air Pressure and Flow

- Keep compressed air at optimal levels for consistent milling performance.

- Fluctuations here can cause uneven grinding or downtime.

Plan Preventive Maintenance

- Set schedules for replacing consumables like nozzles and seals.

- Regular maintenance avoids unexpected breakdowns and costly repairs.

Use Data to Optimize

- Track output particle size and throughput over time.

- Adjust settings based on real data to maintain quality as production scales.

By following these best practices, you can maximize the lifespan and performance of your jet mill while keeping your US-based production running smooth and efficient. EPIC Powder Machinery supports you with solutions tailored for American industry standards, helping you get the most from your jet milling investment.