If you’re in the manufacturing or industrial sector, you already know that building an efficient calcium carbonate powder processing plant is key to unlocking huge value from natural minerals. Whether you’re aiming to boost production quality, cut energy costs, or scale your operations in the world market, understanding the full scope of calcium carbonate powder processing plants is essential. This guide will give you actionable insights into the latest machinery, streamlined production steps, and smart design choices—helping you stay ahead in an increasingly competitive and sustainability-driven industry. Let’s dive into how the right plant setup can transform raw limestone into a powerhouse raw material for countless industrial applications.

Understanding Calcium Carbonate: From Raw Mineral to Industrial Powerhouse

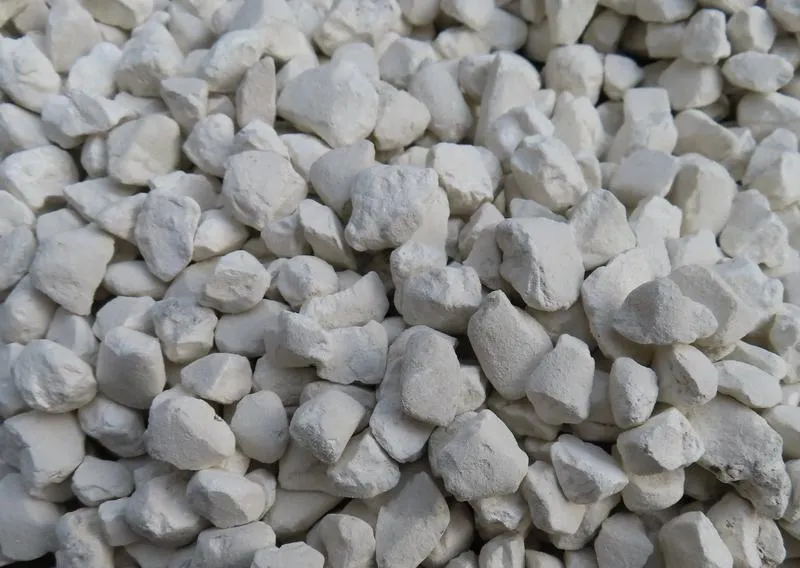

Calcium carbonate (CaCO₃) is a widely used industrial mineral known for its versatility and abundance. Chemically, it is a simple compound made of calcium, carbon, and oxygen, with a stable crystalline structure. Physically, calcium carbonate appears as a white, odorless powder or crystal, boasting properties like high brightness, excellent whiteness, and good chemical stability. These traits make it ideal for diverse applications across industries.

When it comes to calcium carbonate powder, there are two main types: Ground Calcium Carbonate (GCC) and Precipitated Calcium Carbonate (PCC). GCC is produced by mechanically grinding natural limestone, resulting in particle sizes typically ranging from 1 to 40 microns. PCC, on the other hand, is chemically synthesized, offering ultra-fine particle sizes (often below 1 micron) and greater purity, which is essential for high-performance uses.

Sourcing raw materials is critical for producing high-quality calcium carbonate powder. Manufacturers focus on selecting high-purity limestone rich in CaCO3 content, often above 90%. Rigorous quality testing follows, checking factors such as particle size distribution, brightness, and impurity levels. This ensures consistent product quality tailored to specific industrial needs.

Economically, calcium carbonate powder processing is driven by strong demand in sectors like plastics, paper, construction, and pharmaceuticals. The abundance of limestone resources across the U.S., combined with advances in limestone grinding mill and processing technology, keeps production costs competitive. Additionally, calcium carbonate’s role as a cost-effective filler and additive supports ongoing growth and innovation in downstream markets.

In , understanding the chemical properties, types, raw materials, and market drivers behind calcium carbonate powder lays the foundation for successful plant operation and product development in today’s industrial landscape.

The Calcium Carbonate Powder Manufacturing Process: A Step-by-Step Breakdown

Making high-quality calcium carbonate powder starts with raw material preparation. First, we source high-purity limestone, then use primary crushing equipment like jaw crushers or cone crushers to break the rock into manageable pieces. This initial step ensures the material is ready for further processing.

Next up is fine grinding and milling. Popular equipment includes ball mills, Raymond mills, and vertical roller mills, which reduce the crushed limestone into finer, consistent particles. These mills balance efficiency and particle size control, crucial for producing different grades of calcium carbonate powder.

After grinding, air classifiers come into play. These machines separate particles based on size and weight, helping control the powder’s final particle size distribution. This step ensures the product meets industry-specific needs, whether coarse or ultrafine powder.

Some plants apply surface modification or coating to improve properties like dispersibility, brightness, and compatibility with other materials. This treatment enhances the calcium carbonate’s performance in applications like plastics or paper.

Finally, the powder undergoes drying and purification to remove moisture and impurities, ensuring consistent quality. Automated packing systems then prepare the product for shipping, maintaining product integrity.

It’s important to note the process differs between Ground Calcium Carbonate (GCC) and Precipitated Calcium Carbonate (PCC). GCC involves mechanical grinding of natural limestone, while PCC is chemically precipitated, requiring additional steps like chemical reactions and filtration.

This step-by-step process keeps calcium carbonate powder production efficient, meeting high world market standards for quality and performance.

Essential Components of a High-Performance Calcium Carbonate Processing Plant

Setting up a top-notch calcium carbonate powder processing plant requires the right mix of equipment and systems to ensure efficiency, quality, and ease of operation—especially for US-based manufacturers focused on industrial standards and scalability.

Crushing Equipment: Jaw and Cone Crushers

The process starts with reliable crushing equipment. Jaw crushers are used for primary crushing, breaking down large limestone rocks into manageable sizes. Cone crushers follow for secondary crushing, producing uniform-sized particles optimized for milling. Both are robust, energy-efficient, and designed to handle the tough limestone typical in calcium carbonate production.

Grinding Mills: Key to Particle Size Control

Grinding is where you get the fine calcium carbonate powder needed in many industries. Common mills include:

- Vertical agitator ball mills: Great for producing superfine powders with consistent particle distribution.

- Ring roller mills: Efficient for dry grinding applications, reducing dust and improving product quality.

Energy consumption is an important factor here, and mills optimized for lower power use can save operational costs over time.

Auxiliary Systems: Air Classifiers, Dust Collectors, and Coating Reactors

To refine powder quality, air classifiers separate particles by size, ensuring the final product meets precise specs. Dust control is critical, so dust collectors are installed for cleaner air and regulatory compliance. Additionally, some plants use coating reactors to apply surface treatments that improve powder dispersion in end-use products.

Control and Monitoring: PLC-Based Systems

Modern plants rely heavily on PLC (Programmable Logic Controller) systems that offer real-time monitoring and adjustments. Sensors track key parameters like particle size, moisture, and system pressures, allowing operators to optimize performance, reduce downtime, and maintain consistent quality.

Plant Layout: Modular Design and Capacity Planning for the world Market

Modular plant designs are popular for their flexibility and scalability. They allow manufacturers to expand production in phases and adapt to market demands without costly overhauls. When planning a plant in the world, consider:

- Local zoning and industrial area requirements

- Energy efficiency mandates

- Space for auxiliary equipment and future expansion

By focusing on these core components—crushing equipment, efficient grinding mills, auxiliary systems, smart PLC control, and flexible plant design—your calcium carbonate powder processing plant will be well-positioned to meet world industrial standards while maximizing productivity and ROI.

For more on grinding equipment suited to your powder needs, check out our detailed guide on Raymond mills and air classification systems like the air separator.

Key Features and Advantages of EPIC Powder Machinery’s Calcium Carbonate Plants

EPIC Powder Machinery stands out for delivering calcium carbonate processing plants designed with efficiency, durability, and adaptability in mind. Here’s what makes their plants a smart choice for China manufacturers:

Energy Efficiency and Advanced Grinding Technology

- Roller Pressure Technology: Reduces energy consumption during grinding by applying consistent pressure, improving throughput.

- Closed-Circuit Grinding: Recirculates material for finer particle control with less waste and lower power use.

Scalability and Customization

- Plants can be tailored for small, medium, or large-scale production, meeting varied customer demands.

- Modular designs allow for easy upgrades or expansion as business needs grow.

Durability and Low Maintenance

- Built with high-quality materials that withstand harsh industrial environments.

- Simplified machine design means reduced downtime and easier repairs.

- Remote diagnostics capabilities allow operators to troubleshoot and optimize performance without onsite visits.

Environmental Compliance Features

- Integrated dust suppression systems help keep air clean, meeting EPA regulations.

- Innovative CO2 recapture solutions reduce the plant’s carbon footprint, a big plus for sustainability goals.

ROI Case Study: Midwest Plant Success

| Metric | Result |

|---|---|

| Energy savings | 15% reduction vs. traditional plants |

| Production increase | 20% higher output with same raw inputs |

| Maintenance downtime | Cut by 30% with durable and remote systems |

| Environmental impact | Achieved local emission standards easily |

This case highlights how investing in EPIC Powder Machinery’s technology pays off quickly through lower running costs, higher efficiency, and regulatory ease. For US producers looking to stay competitive and green, these plants bring solid value.

For more on grinding technology, check out our details on the calcium carbonate grinding mill guide.

Applications of Calcium Carbonate Powder: Driving Innovation Across Industries

Calcium carbonate powder plays a big role in many industries across the U.S. Here’s a quick look at how it’s used today:

- Plastics and Rubber: Calcium carbonate acts as a safe, non-toxic filler. It improves product strength and reduces costs without compromising quality.

- Paper and Coatings: It brightens and smooths paper, making it ideal for printing and packaging. In coatings, it enhances durability and finish.

- Construction: This powder is essential in sealants, adhesives, and concrete additives. It boosts strength, improves workability, and cuts down on shrinkage.

- Pharmaceutical and Food: FDA-compliant calcium carbonate is used in medicines and as a dietary supplement. It’s trusted for its purity and safety.

- Cosmetics and Agriculture: Emerging uses include skincare products and fertilizers. Calcium carbonate helps improve texture in cosmetics and soil quality in farming.

With steady market growth, calcium carbonate powder continues to drive innovation, offering versatile, cost-effective solutions for U.S. manufacturers.

Setting Up Your Calcium Carbonate Powder Processing Plant: Practical Guide for US Manufacturers

Starting a calcium carbonate powder processing plant in the US requires smart planning and knowing the local rules. Here’s a straightforward guide to help you set up efficiently.

Site Selection and Permitting

- Location matters: Choose a site near limestone sources to cut raw material transport costs.

- Zoning and permits: Check for industrial zoning and environmental permits from state and local agencies. Expect air quality and dust control standards to meet EPA regulations.

- Infrastructure: Ensure good access to roads, power, and water. These help keep your plant running smoothly.

Investment and Financing

- Budget planning: Typical setup costs can range widely, depending on plant scale and tech choice, from several hundred thousand to millions.

- Funding options: SBA loans are great for China manufacturers. They offer lower interest rates and longer terms. Be ready with a solid business plan and financial projections.

- Cost-saving tips: Investing in energy-efficient equipment, like vertical roller mills and dust collectors, can reduce long-term expenses.

Vendor Selection: Why EPIC Powder Machinery?

- EPIC Powder Machinery is a proven name in the world market for calcium carbonate plants.

- They offer scalable solutions from small to large operations, tailored to your capacity needs.

- Their systems focus on energy efficiency, durability, and come with remote diagnostic options, helping you minimize downtime.

Operational Best Practices

- Workforce training: Skilled operators ensure safe and optimal performance, especially in grinding and classification processes.

- Safety: Implement strict dust control and personal protective equipment (PPE) policies to protect workers and comply with OSHA.

- Maintenance: Use predictive maintenance to keep crushers, mills, and classifiers running without unexpected breakdowns. This improves plant uptime and lowers costs.

Challenges and Solutions

- Energy costs: Grinding can be energy-intensive. EPIC’s roller pressure tech and closed-circuit grinding help improve efficiency.

- Solar integration: Consider solar power to cut utility bills and boost sustainability, especially in sunny regions.

- Scaling up: Start with a modular plant design for easy expansion as demand grows.

With the right site, financing, equipment choice—especially from trusted suppliers like EPIC Powder Machinery—and operational focus, your calcium carbonate powder processing plant can thrive in the world industrial landscape.