Cathode materials can be categorized into lithium cobalt oxide, lithium manganese oxide, lithium iron phosphate, and ternary materials. Among these, lithium iron phosphate is an olivine-structured cathode material primarily composed of lithium, iron, phosphorus, and carbon sources. It is manufactured through processes including raw material mixing, drying, sintering, and grinding.

The particle size distribution of lithium iron phosphate crystals significantly impacts the rate performance of cathode materials. Under identical conditions, a narrower particle size distribution shortens lithium ion transport paths, resulting in superior rate performance—meaning faster charging and discharging speeds for lithium batteries.

The preferred grinding equipment for LFP is the jet mill. Utilizing jet milling principles, it produces particles with a narrow size distribution, eliminating over-grinding and large particles while achieving low fine powder rates and high yield. This makes it the top choice for the vast majority of battery material manufacturers.

How to Choose the Right Air-Jet Mill

Choosing the right air jet mill for pulverizing lithium iron phosphate requires comprehensive consideration of factors such as material characteristics, process requirements, and equipment performance. The following are key points:

Material Properties

Lithium iron phosphate is a high-hardness, brittle material that demands high wear resistance and grinding efficiency from processing equipment. We recommend prioritizing fluidized bed jet mills or counter-jet mills. These two types of equipment effectively handle high-hardness materials, minimize equipment wear, and ensure uniform particle size distribution.

Process Requirements

Particle Size Control: Lithium iron phosphate imposes stringent particle size requirements, necessitating micron-level or even nanometer-level precision. Fluidized bed jet mills achieve narrow particle size distributions through precise control via classification wheels. Opposed-jet mills leverage high-speed particle collisions for superior grinding efficiency and strong particle size controllability.

Production Capacity Matching: Select appropriate equipment based on production scale. Benchtop units suit small-scale experiments or pilot testing, while large-scale production requires vertical or horizontal industrial units to balance output and costs.

Special Requirements: For high-temperature, flammable, or explosive environments, incorporate safety measures like inert gas protection and explosion-proof designs. For ultra-high-purity products, choose equipment with ceramic linings or high-purity materials to minimize impurity contamination.

Equipment Performance

Grinding Efficiency and Energy Consumption: Fluidized bed jet mills feature low energy consumption, making them suitable for large-scale continuous production. Opposed jet mills deliver strong grinding power but exhibit relatively higher energy consumption, requiring assessment against actual costs.

Classification Precision: High-quality jet mills feature efficient classification wheels that precisely separate coarse and fine particles, preventing over-grinding or uneven particle size distribution. Opt for equipment with adjustable classification wheel speeds to accommodate varying particle size requirements.

Automation Level: Prioritize PLC touchscreen-controlled systems supporting parameter storage, real-time monitoring, and remote adjustment for streamlined production management and quality control.

Materials and Maintenance

Wear-Resistant Materials: Critical components such as the grinding chamber and nozzles should be constructed from wear-resistant materials like hard alloys, ceramics, or high-chromium stainless steel to extend equipment lifespan and reduce maintenance costs.

Ease of Cleaning and Maintenance: The equipment structure should eliminate cleaning blind spots, facilitate disassembly and cleaning, and minimize the impact of residue on product quality. Regularly inspect nozzle wear and promptly replace vulnerable parts.

Total Cost

Purchase Cost: Fluidized bed jet mills carry a higher price tag but offer lower long-term operating costs. Opposed jet mills require relatively lower initial investment, yet may incur higher energy consumption and maintenance expenses. A comprehensive evaluation balancing budget constraints and production efficiency is essential.

Operating Cost: Select cost-effective equipment by considering factors such as air source pressure, energy consumption, and replacement frequency of wear parts. Some manufacturers offer equipment leasing or customized services, allowing flexible selection based on actual operational needs.

EPIC Powder Recommended Models:

Fluidized Bed Air Mill: Suitable for large-scale continuous production, featuring a narrow particle size distribution and low energy consumption. Ideal for lithium iron phosphate production requiring high purity and precise particle size control.

Disc-Type Air Mill: Features high grinding efficiency and can process high-hardness materials. Suitable for small-batch production or scenarios demanding exceptional particle size uniformity.

It is recommended to consult with equipment manufacturers prior to purchase. Provide material samples for testing to obtain actual grinding results and process parameters, ensuring precise alignment between equipment and production requirements.

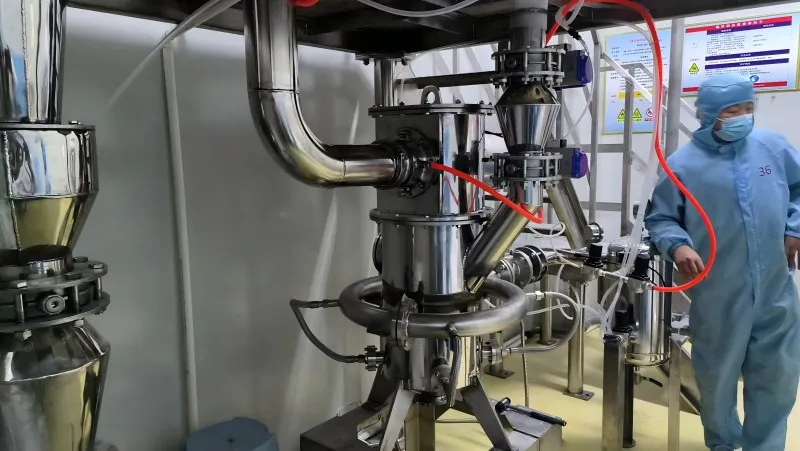

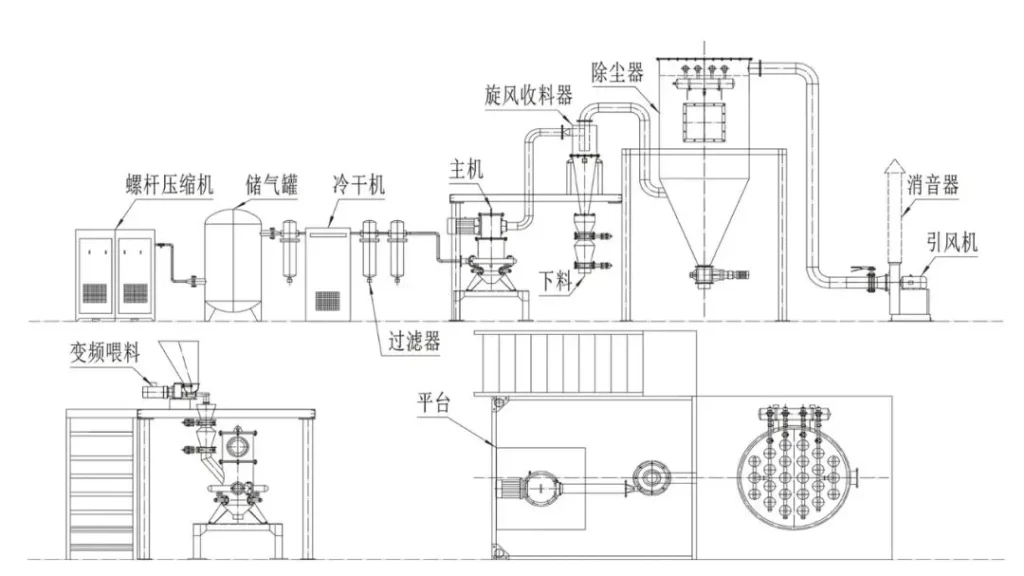

Working Principle of Lithium Iron Phosphate jet Milling Machine

The lithium iron phosphate jet mill production line primarily consists of a grinding main unit (with the supersonic Laval nozzle as its core technology), cyclone collector, dust collector, electrical control cabinet, air compressor, and other components. Working Principle: The equipment utilizes purified, dry compressed gas. This gas stream carries the material at high velocity, imparting significant kinetic energy. Within the grinding chamber, this creates high-speed collisions and intense friction between material particles. Simultaneously, the high-velocity gas stream exerts a shearing force on the material, thereby achieving the grinding effect.

The MQW series air jet mill incorporates an integrated classification system, serving as a combined unit that simultaneously performs grinding and classification. Qualified fine powder is classified directly within the air jet mill and collected by a cyclone separator, preventing over-grinding while enhancing production capacity. Variable frequency control enables direct adjustment of particle size distribution, achieving a minimum D97 ≤ 2 μm with high precision and narrow distribution.

Advantages of EPIC powder air jet mill for lithium iron phosphate production

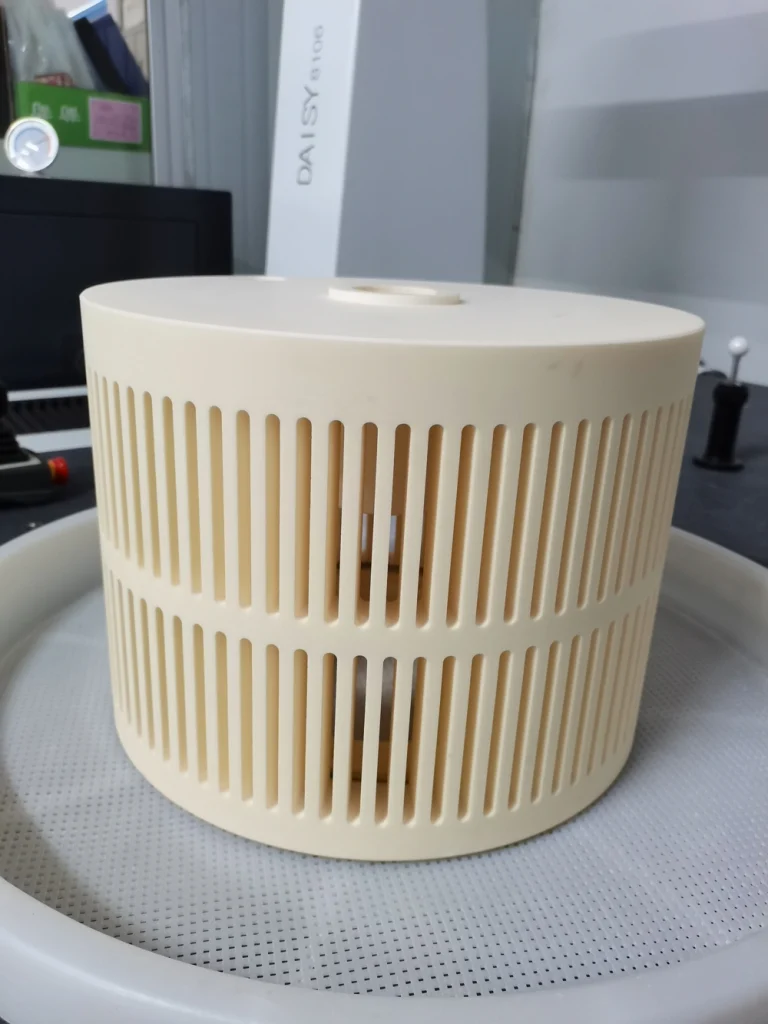

Replaceable Ceramic Lined Grinding Chamber

Excessive impurity content in lithium iron phosphate increases the self-discharge rate of lithium batteries, shortening their lifespan. Based on the characteristics of cathode materials, Zhongda employs an integrally sintered ceramic grinding chamber lined with 99% alumina, zirconia, and other ceramics. This design prevents impurity introduction at the source, ensuring the purity of lithium iron phosphate materials.

Controllable Particle Size Range for Lithium Iron Phosphate

By adjusting air pressure and grinding pressure in conjunction with feed rate, the particle size of finished lithium iron phosphate can be effectively controlled. The final product achieves a D97 ≤ 2 microns particle size.

Advantages of Positive Airflow Pulverizer Equipment

Product Particle Size: Controllable particle size range of 2μm to 150μm. Direct control of particle size distribution via variable frequency drive, achieving a minimum D97 ≤ 2μm with high precision and narrow distribution.

Feed Particle Size: ≥30 mesh. Higher output with finer feed material. Coarser feed requires a pre-installed coarse crusher.

Fully Ceramic Construction: All material-contact parts are ceramicized, ensuring no magnetic substances are introduced.

Feeding Method: Utilizes a hopper + variable-frequency screw conveyor + variable-frequency feed control for precise, controllable dosing.

Discharge Method: Qualified ground material is collected via a dust collector or cyclone separator. Discharge options include electric discharge valves, pneumatic butterfly valves, or manual butterfly valves per customer requirements.

Product Quality: All MQW series jet mills comply with GMP standards. Utilizing advanced technical drawings and European/American product design processes, the equipment features mature technology with efficient and stable operation.

Safety Performance: Equipment is easy to disassemble, clean, and maintain. The system operates in a sealed environment with low noise levels, ensuring a clean and environmentally friendly production process.

Operating Environment: No special workshop requirements. The site remains dust-free and pollution-free with a negative pressure system.

Temperature Control: The jet mill provides constant temperature control, enabling 24/7 continuous production without temperature rise. Maximum operating temperature ≤25°C.

Supersonic Laval Nozzle: Zirconia ceramic nozzle.

Post by Alex Liu

Thanks for reading. I hope my article helps. Please leave a comment down below. You may also contact EPIC Powder online customer representative for any further inquiries.