Understanding the Unique Challenges of NdFeB in Air Jet Milling

When milling NdFeB (Neodymium-Iron-Boron) powder using an air jet mill, you’re dealing with a material that comes with its own set of challenges. NdFeB contains rare-earth elements like neodymium and terbium, which are highly reactive and prone to oxidation. Exposure to oxygen during milling can degrade the magnetic properties, reducing the powder’s effectiveness in making high-performance magnets.

The jet milling process itself involves high-velocity particle impact that generates heat and fine dust. This combination raises concerns about potential oxidation, but also about dust explosions in the milling chamber, especially since ultrafine powder particles can be highly combustible under the right conditions.

Common issues with NdFeB jet milling include inconsistent particle size distribution and contamination from the milling environment. Particle size inconsistency can affect downstream processes like sintering and magnet coercivity, while contamination lowers product purity and performance. Controlling these factors requires careful attention to both the equipment setup and the milling environment.

Core Precaution #1: Implementing Inert Gas Protection to Prevent Oxidation

When using an air jet mill to produce NdFeB powder, preventing oxidation is crucial due to the rare-earth elements being highly reactive. The best way to protect the powder is by implementing an inert gas environment, with nitrogen circulation being the most practical choice.

Why Nitrogen Circulation?

- Cost-effective: Nitrogen is cheaper than argon, making it suitable for continuous, large-scale milling.

- Closed-loop system: Nitrogen can be recirculated with low oxygen content (around 200 PPM), minimizing gas waste and contamination risks.

- Stable atmosphere: Maintains a consistent low-oxygen environment that safeguards NdFeB powder from oxidation during milling.

| Feature | Nitrogen | Argon |

|---|---|---|

| Cost | Lower | Higher |

| Availability | Readily available | Less common |

| Gas Density | Lower | Higher (better inertness) |

| Suitability for Scale | Ideal for large-scale | Better for small scale |

Setup Guidelines for Nitrogen Protection

- Nitrogen purging: Flush the mill chamber thoroughly before operation to reduce oxygen levels.

- O₂ sensors: Continuously monitor oxygen inside the mill to keep it well below 500 PPM, ideally near 200 PPM.

- Gas recirculation: Use a closed-loop nitrogen circulation system with filters to maintain purity and minimize moisture.

EPIC Integration Highlights

EPIC Powder Machinery’s JetMill series comes with integrated options for inert gas protection, including nitrogen circulation systems and cryogenic cooling adaptations. These setups improve powder quality and reduce oxidation risk.

- Cryogenic options enhance particle brittleness, easing the milling process.

- Inline oxygen monitoring is standard for real-time atmosphere control.

Best Practices

- Perform inline oxygen measurement to adjust nitrogen flow dynamically.

- Use data from oxygen sensors to fine-tune purging cycles.

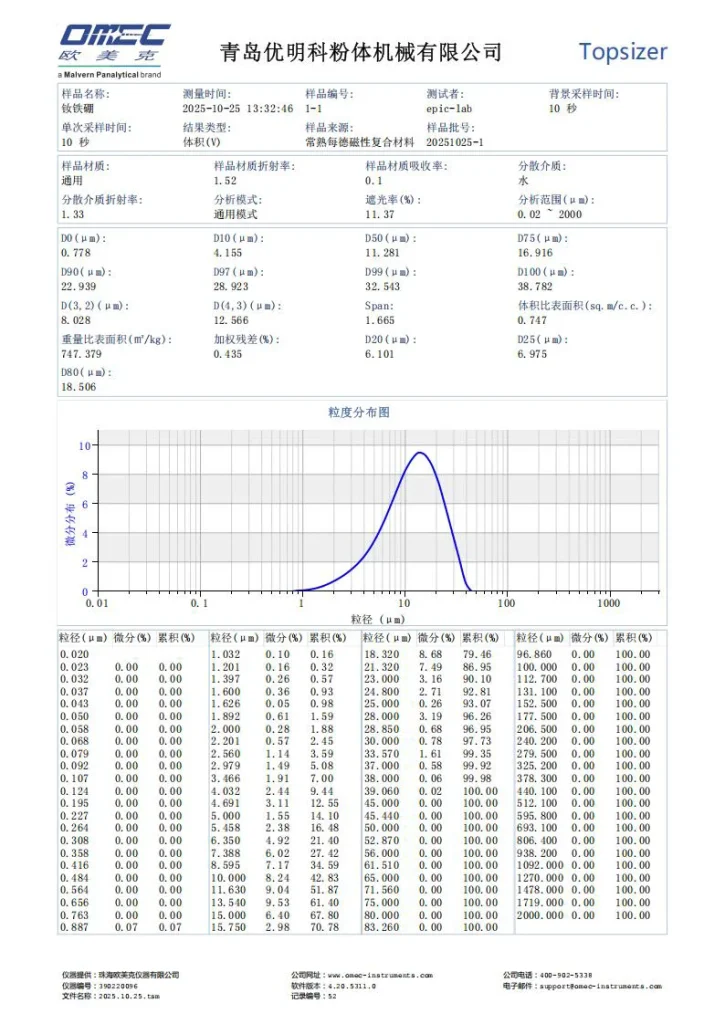

- One case study with EPIC systems showed a consistent oxygen level below 200 PPM, resulting in high-purity NdFeB powder with a fineness of D100: 45 μm.

For detailed guidance on selecting the right air jet mill for NdFeB with inert gas protection, explore this how to select the best air jet mill for NdFeB powder in 2025.

This combination of nitrogen circulation, monitoring, and advanced milling technology is key to unlocking high-quality NdFeB powder without oxidation damage.

Core Precaution #2: Optimizing Process Parameters for Powder Quality and Yield

Controlling process parameters is key to producing high-quality NdFeB powder with good yield in an air jet mill. Here’s how to fine-tune the main elements:

Particle Size Control

- Classifier speed: Adjusting this controls particle size distribution. Higher speeds give narrower, finer particles—aim for consistent D100 around 45 μm to match desired specs.

- Grinding pressure: Fine-tune the grinding pressure to balance particle breakage and avoid overgrinding, which can cause fines that reduce powder flow and magnetic properties.

Feed Rate and Nozzle Tuning

- Feed rate: Keep it steady and optimal to prevent overloading the mill or inconsistent milling. Too high reduces milling efficiency; too low wastes capacity.

- Laval nozzles: Proper nozzle configuration boosts particle acceleration and impact energy. Select nozzles designed for NdFeB to maximize grinding efficiency without worry of nozzle wear.

Lubricant Addition

- Add small amounts of silicone oil during milling to stabilize particles, reduce static build-up, and prevent particle agglomeration. This is essential especially for ultrafine powders.

Troubleshooting Tips

- Run flow simulations to check gas and powder dynamics inside the mill. They help detect potential dead zones or uneven particle trajectories that cause size inconsistency.

- Use hydrogen decrepitation as a pre-milling step to gently crack NdFeB chunks before milling. This improves grinding efficiency and powder uniformity.

| Parameter | Effect | Recommendation |

|---|---|---|

| Classifier Speed | Particle size distribution | Adjust for narrow size range |

| Grinding Pressure | Breakage vs overgrinding | Balance to avoid fines |

| Feed Rate | Milling efficiency | Keep stable & within optimal range |

| Laval Nozzle Type | Particle impact & velocity | Use mill-specific nozzle designs |

| Silicone Oil Add. | Powder stabilization | Add in small controlled amounts |

Optimizing these parameters ensures a consistent powder quality with minimal waste. For example, maintaining a system oxygen content below 200 PPM during nitrogen circulation helps preserve magnetic properties, while fine-tuning particle size improves sintering and coercivity.

For more on milling techniques and equipment options, you can explore advantages of ceramic-lined air jet mills.

Core Precaution #3: Ensuring Operator and Equipment Safety

Safety is critical when using an air jet mill to produce NdFeB powder due to the fine, combustible nature of the material. Here are key measures to protect both operators and equipment:

Dust and Explosion Mitigation

- Use ATEX-certified enclosures designed to handle explosive dust environments.

- Ensure proper grounding of all equipment to avoid static sparks.

- Install spark detection and suppression systems to catch ignition sources early.

PPE and Ventilation

- Operators should wear respirators to prevent inhalation of fine particles.

- Use static-dissipative clothing to reduce static buildup risks.

- Maintain effective ventilation systems equipped with HEPA filters to capture airborne NdFeB dust safely.

Equipment Maintenance

- Regularly inspect mill liners for wear and replace them promptly to avoid contamination and equipment failure.

- Utilize quick-disconnect modules for fast, safe access during cleaning or repairs, reducing downtime and exposure.

Emergency Protocols

- Establish clear shutdown procedures to quickly stop the mill if abnormal conditions like high oxygen levels or sparks are detected.

- Train operators on emergency response to ensure rapid action and limit hazards.

Taking these safety steps seriously protects your team and ensures reliable, continuous NdFeB powder production without costly incidents or equipment damage. For a deeper dive into optimizing grinding safety and equipment, consider exploring best practices in related jet milling processes like those detailed in dry grinding and air classification systems.

Core Precaution #4: Quality Control and Post-Milling Handling

Maintaining top-notch quality control is essential when producing NdFeB powder with an air jet mill. Inline monitoring tools like laser diffraction systems help keep particle size distribution consistent, while magnetic tests ensure the powder’s coercivity and other magnetic properties meet strict standards. These checks help catch any deviations early, preventing costly product issues downstream.

Proper storage after milling is just as important. Use inert vacuum-sealed pouches to protect the powder from moisture and oxygen, which can cause oxidation and degrade magnetic performance. Keep humidity tightly controlled in storage areas to further minimize any risk of deterioration.

When scaling from lab to industrial production, aligning milling parameters with quality assurance processes ensures both high yield and return on investment. Consistency becomes key as batches grow larger, so monitoring and adjustment protocols must be robust.

Finally, be sure your milling setup complies with standards like ISO 9001 for quality management and REACH regulations for chemical safety. These certifications not only guarantee product safety but also help in gaining customer trust and market access.

For deeper insights into powder size control and milling techniques, exploring advanced grinding technologies such as those explained in the discussion on jet mill micronizer vs air classifier mill key differences can be very helpful.

Advanced Tips: Enhancing Efficiency with EPIC Powder Machinery Solutions

When it comes to producing high-quality NdFeB powder, choosing the right jet mill system can make a big difference. EPIC Powder Machinery offers customizable solutions that cater to specific milling needs, improving efficiency and powder quality.

Customization Options: Fluidized Bed vs Spiral Jet Mills

| Feature | Fluidized Bed Jet Mills | Spiral Jet Mills |

|---|---|---|

| Grinding Mechanism | Fluidized particle flow | Spiral gas flow with classifier |

| Particle Size Control | Excellent for uniform sizes | Good control, adjustable fineness |

| Suitable Powder Type | Fine, fragile powders | Hard and coarse powders |

| Energy Consumption | Moderate | Generally lower |

| Maintenance Complexity | Moderate | Simpler design |

Choosing between fluidized bed and spiral jet mills depends on your specific NdFeB powder properties and production scale requirements.

Case Study: EPIC Nitrogen System Success Story

A leading magnet manufacturer implemented EPIC’s closed-loop nitrogen circulation system in their jet milling process. This upgrade cut oxygen content consistently below 200 ppm, reducing oxidation-related defects by over 30%. The system also improved particle fineness, achieving a D100 of 45 μm, enhancing powder performance for sintered magnet applications. This real-world success highlights how nitrogen-protected air jet mills can safeguard rare-earth powders during ultrafine grinding.

Future-Proofing: Cryogenic Enhancements & AI-Driven Parameters

EPIC Powder Machinery is also innovating with cryogenic jet milling options. Cooling the material below ambient temperatures reduces heat-induced oxidation and helps maintain magnetic properties during milling. Additionally, AI-driven process controls automatically optimize classifier speeds, feed rates, and nozzle pressures in real-time, boosting yield while maintaining powder quality.

For a deeper dive into optimizing powder production with advanced machinery, exploring solutions like those found in the non-metallic mineral milling cases can be insightful. These demonstrate tailored approaches for grinding systems similar in complexity to rare-earth metal powders.

By integrating EPIC’s flexible machinery, your facility can confidently scale NdFeB powder production while protecting quality and safety.