If you’re trying to produce ultrafine, high‑quality powder, choosing the right fine powder grinding mill can make or break your results.

Maybe you need a tighter particle size distribution for better product performance. Maybe your material is heat‑sensitive, abrasive, or must meet strict purity standards. Or maybe your current mill just can’t hit the micron range you need—no matter how hard you push it.

This guide is going to walk you through exactly what matters in a fine powder grinding mill:

the types of mills (jet mills, air classifier mills, ring roller mills and more), the applications that demand ultrafine powders, and the selection tips that real plants use to avoid costly mistakes.

Along the way, you’ll see where EPIC Powder Machinery fits in—with practical, engineering‑driven solutions instead of marketing fluff.

If you’re serious about micron powder production and want consistent, industrial‑scale results, keep reading.

Do you want to know how to choose the right Fine Powder Grinding Mill?

What Is a Fine Powder Grinding Mill?

A fine powder grinding mill (also called an ultrafine grinding mill, superfine powder mill, or industrial powder grinder) is specialized particle size reduction equipment designed to turn granular or coarse material into micron-level powder with a controlled particle size distribution (PSD). I use these systems to deliver consistent, high-performance powders for industrial production, not just basic size reduction.

Basic Definition and Working Principle

In simple terms, a fine powder grinding mill:

- Takes in: crushed or pre-processed material

- Applies energy: through impact, shear, attrition, and/or compression

- Separates fine from coarse: using an integrated or external air classifier

- Returns oversize: back to the grinding zone until it meets the target size

The process is usually continuous and often operates in a closed-circuit grinding system or closed-loop powder milling system, where:

- Material is fed into the mill (screw feeder, rotary feeder, or dosing system).

- Grinding happens between rollers, pins, hammers, media, or via air jets.

- Ground particles are carried by airflow to an ultrafine air classifier.

- Fine powder passes to the collector; coarse powder is recirculated.

This is how I achieve stable, repeatable fineness in real industrial conditions.

Fine vs Ultrafine Powder: Micron and Submicron

When we talk about “fine” and “ultrafine,” we’re really talking about particle size ranges:

- Fine powder:

- Typically 10–200 μm (microns)

- Common for food, spices, plastics masterbatch, basic mineral fillers

- Ultrafine powder / Superfine powder:

- Typically 1–10 μm

- In advanced systems, down to submicron (<1 μm)

- Used for high-end coatings, pigments, pharmaceuticals, and high-performance fillers

A dedicated ultrafine grinding mill, such as a jet mill grinder, air classifier mill, or ball mill with classifier, is usually required once you aim below about 20 μm with a tight PSD.

Why Particle Size Distribution (PSD) Matters

It’s not enough to hit an “average” size; the shape of the PSD drives your product performance. In practice, I focus on:

- Narrow PSD (sharp cut)

- Better flowability and packing density

- More consistent reaction rate, dissolution, or color strength

- Reduced dust and segregation in handling

- Controlled top cut (D90 / D97)

- Limits the number of coarse particles that can cause surface defects, poor gloss, rough mouthfeel, or low strength

- Optimized fines content (D10)

- Too many fines → caking, poor flow, dust explosions risk

- Too few fines → weak performance, poor coverage or reactivity

With proper particle size distribution control via classification, I can tune the powder to match very specific industrial performance targets.

Core Components of a Fine Powder Grinding System

A complete fine powder production line or powder grinding plant usually includes:

- Feeding system

- Screw feeder, rotary valve, or loss-in-weight feeder

- Designed for stable, controlled feed to the mill

- Grinding mill

- The core unit: jet mill, air classifier mill, ring roller mill, vibration grinding mill, ball mill, pin mill, or hammer mill

- Selected based on material hardness, heat sensitivity, and target fineness

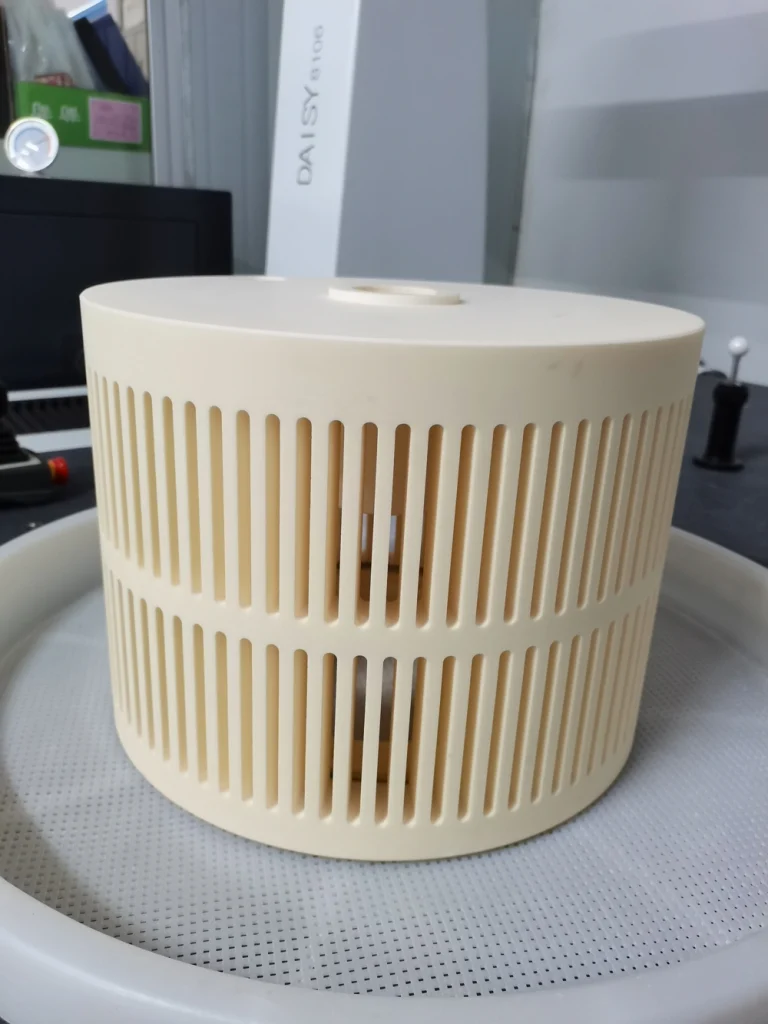

- Air classifier / classification system

- Integrated in an air classifying mill system or external in a closed-circuit ball mill

- Controls fineness, typically via classifier speed and airflow rate

- Air handling and airflow system

- Fans, blowers, and ducting to move material and control residence time

- Critical for dry grinding technology and low temperature grinding

- Dust collection and filtration

- Bag filters, cartridge filters, or cyclones

- Ensure a dust-free grinding system, high product recovery, and compliance with safety standards

- Control and automation

- PLC or DCS control for classifier RPM, mill speed, airflow, feed rate

- Data logging for quality assurance and process optimization

- Contact parts and lining materials

- Stainless steel grinding chamber, wear-resistant grinding parts, ceramics, or special alloys

- Designed around abrasiveness, purity requirements, and metal contamination control

By integrating these components correctly, I can build custom powder grinding systems and industrial fine powder processing lines that deliver consistent micron powder production for global markets.

Why Use a Fine Powder Grinding Mill?

A fine powder grinding mill isn’t just “nice to have” – it’s often the only way to hit modern quality, cost, and safety targets in powder processing.

Better Product Quality and Consistency

With a stable fine powder grinding mill, you get:

- Tight particle size distribution (PSD) for repeatable performance batch after batch

- Uniform color, texture, and density in minerals, chemicals, pigments, food, and pharma

- Stable downstream behavior in mixing, granulation, coating, or extrusion

Consistent PSD means fewer rejects, fewer customer complaints, and a much easier time scaling up production.

Improved Solubility, Reactivity, and Flowability

Fine and ultrafine grinding directly upgrades how your product behaves:

- Smaller particle size = higher surface area, which boosts solubility (APIs, food additives), reactivity (chemicals, catalysts), and dispersion (pigments, fillers).

- Better flowability and packing for powders going into silos, bags, feeders, or 3D printing systems.

- Cleaner blending with less segregation in

How Fine Powder Grinding Mills Work

A fine powder grinding mill breaks down material by combining several forces in one controlled system. Once you understand these basics, it’s much easier to choose the right industrial powder grinder and keep it running at its best.

Main Grinding Mechanisms

Inside a fine powder grinding mill or ultrafine grinding mill, particles are reduced mainly by:

- Impact – high-speed hammers, pins, or particles hit the material and shatter it (pin mill, hammer mill, jet mill).

- Shear – material is “sliced” between fast-moving surfaces (air classifier mill, some rotor mills).

- Attrition – particles rub and grind against each other or against media (ball mill, vibration grinding mill).

- Compression – material is squeezed between rollers or rings (ring roller mill, Raymond-type mills).

Most particle size reduction equipment uses a mix of these forces. We tune the design so you get the fineness you want with minimum energy.

Closed-Circuit vs Open-Circuit Systems

Your fine powder grinding mill can run:

- Open-circuit: Material passes through once, no built-in separation. It’s simpler but the particle size distribution (PSD) is usually broader.

- Closed-circuit: A classifier (often an ultrafine air classifier) sits in the loop. Fine powder is removed as product, coarse particles are sent back to the mill.

- Result: tighter PSD, stable quality, and better energy efficiency, especially for micron and ultrafine powder.

Most modern fine powder production lines use some form of closed-circuit or closed-loop powder milling system to keep quality under tight control.

Classification, Recirculation, and Narrow PSD

To get a narrow, consistent PSD, we rely on:

- Integrated or external classifier – separates particles by size or mass in real time.

- Recirculation loop – oversize particles are automatically returned to the mill until they meet the target size.

- Fine tuning – adjust classifier speed and airflow to move the “cut point” and control the PSD bandwidth.

This is how a superfine powder mill can hold a very tight spec even when feed quality changes.

Airflow, Speed, and Grinding Media

Fine grinding performance is all about control:

- Airflow

- In jet mills and air classifier mills, airflow moves material, cools the process, and helps classification.

- Higher airflow generally carries finer particles to the classifier faster, but too much flow can reduce grinding time.

- Rotor / mill speed

- Higher speed = stronger impact and shear = finer powder, but also more wear and energy use.

- We balance speed to hit your fineness target without burning power or parts.

- Grinding media (ball mills, vibration mills)

- Size: smaller media = finer grinding, but slower throughput.

- Material: steel, ceramic, or special alloys to match hardness and purity requirements.

When we design or upgrade a powder pulverizer machine or fine particle milling system, these parameters are what we optimize to deliver stable micron powder at the lowest cost per ton.

For a practical look at how this works in real plants, you can see how we build complete mineral powder grinding lines for fillers like calcium carbonate in our guide to heavy calcium carbonate grinding and applications.

Types of Fine Powder Grinding Mills

Common industrial fine powder grinding mill types

When I design a fine powder grinding line, I usually start by shortlisting from these core mill types:

- Jet mill (spiral / fluidized bed jet mill) – uses high‑speed air jets, no mechanical media contact.

- Air classifier mill (air classifying mill) – impact grinding + built‑in air classifier in one housing.

- Ring roller mill / Raymond roller grinding mill – compression and shear between rollers and ring for minerals.

- Vibration grinding mill (vibro mill) – high‑frequency vibration with media for fine and ultrafine powders.

- Ball mill with classifier – classic closed‑circuit grinding with external air classifier.

- Pin mill grinder – high‑speed pins for impact grinding of medium‑hard materials.

- Hammer mill for fine grinding – hammers + screens for coarse to medium‑fine powders.

Each of these is a proven industrial powder grinder solution in real production lines, not just lab gear.

Matching mill type to material and fineness

Here’s how I normally match the mill to your material and target size:

- Soft to medium, heat‑sensitive, high‑purity (APIs, pigments, specialty chemicals)

→ Jet mill or air classifier mill for micron and submicron powder with very clean surfaces. - Nonmetallic minerals (calcium carbonate, talc, quartz, kaolin, perlite, etc.)

→ Ring roller mill for 325–2500 mesh; ball mill + classifier when you need flexible fineness and very high capacity. For example, our calcium carbonate and perlite powder grinding lines are built around these solutions on EPIC Powder Machinery’s powder grinding platform. - Tough, abrasive, high-volume raw minerals

→ Ball mill with classifier or ring roller mill, with wear‑resistant liners and parts. - Food, spice, and general chemicals

→ Pin mill or hammer mill for efficient medium‑fine grinding and easy cleaning. - R&D, small batches, special ultrafine projects

→ Vibration grinding mill, or lab‑scale jet mill / air classifier mill for flexible trials.

If you’re unsure what’s realistic for your powder, I always recommend starting with lab or pilot tests on your material at a technical center like ours before locking in the mill type.

Pros and cons of fine powder grinding technologies

Each fine powder grinding mill technology has its trade‑offs:

- Jet mill / ultrafine grinding mill

- Pros: Very fine (down to d97<3–5 μm), narrow PSD, low contamination, great for heat-sensitive and high‑purity powders.

- Cons: Higher energy use, lower capacity, needs compressed air and a clean, dry feed.

- Air classifier mill

- Pros: Grinding + classification in one machine, adjustable fineness on the fly, good particle size distribution control, solid balance of cost, energy, and performance.

- Cons: Not as ultra‑clean as jet mills, more wear when used on very abrasive minerals.

- Ring roller mill (Raymond type)

- Pros: Very energy‑efficient, stable continuous production, ideal for ultrafine mineral powder processing (e.g., CaCO₃ 600–2500 mesh), lower operating cost per ton.

- Cons: Mainly for nonmetallic minerals; not ideal for sticky or fibrous materials.

- Vibration grinding mill

- Pros: Compact footprint, strong fine‑grinding ability, good for small to medium batches and hard materials.

- Cons: Higher vibration, more demanding on foundations and maintenance.

- Ball mill with classifier system

- Pros: Very flexible, handles wide hardness range, large‑scale micron powder production, easy to scale up.

- Cons: Higher energy consumption, bigger system, more media and liner wear.

- Pin mill / hammer mill

- Pros: Simple, robust, low CAPEX, great for food, spices, and general chemicals.

- Cons: Limited in ultrafine range; when you need superfine powder or tight PSD, you’ll need to step up to an air classifier mill or jet mill grinder.

In real projects, I don’t pick a mill in isolation. I look at your material properties, target fineness, capacity, and purity level, then build a custom powder pulverizer system—often combining pre‑crushing, drying, and classification—to hit your spec with the lowest total cost.

Jet Mill for Ultrafine Powder

A jet mill is a fine powder grinding mill that uses high-speed compressed air (or steam) instead of mechanical blades. Particles collide with each other at very high velocity, breaking down into micron and submicron powder with almost no heat buildup and very low contamination.

How jet mills grind with high-speed air jets

In a jet mill grinder, compressed air is injected through nozzles into a grinding chamber:

- The high-speed air jets accelerate particles to supersonic speeds

- Particles impact and abrade each other (particle–particle collision)

- Finer particles are carried out by the airflow, while coarse ones stay until they’re small enough

This pure gas-energy grinding makes jet mills ideal ultrafine grinding mills for critical and sensitive powders.

Spiral jet mill vs fluidized bed jet mill

There are two main industrial jet mill types:

- Spiral jet mill

- Tangential air inlets create a spiral

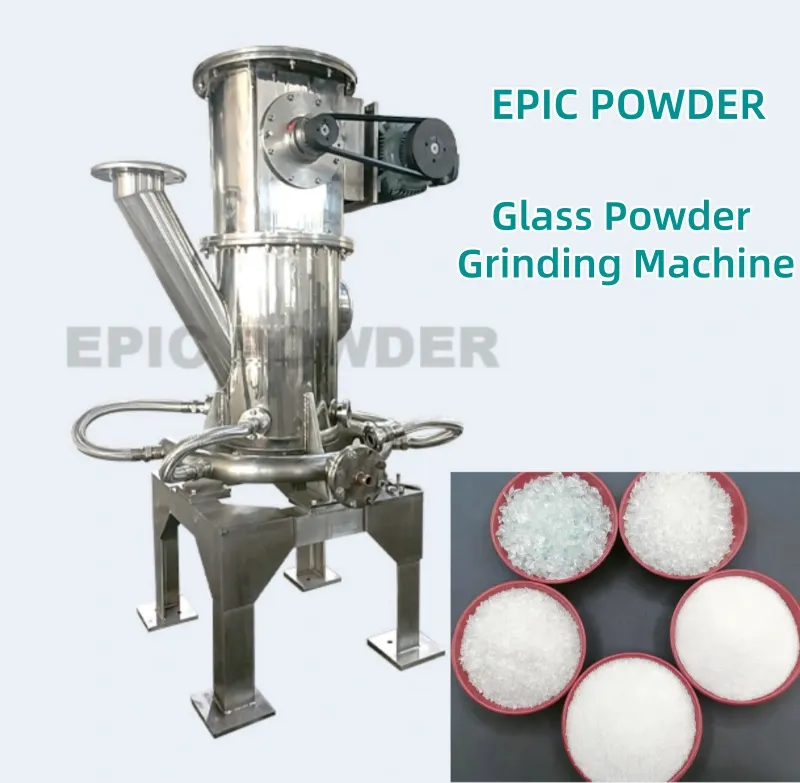

Air Classifier Mill (Air Classifying Mill)

An air classifier mill (often called an air classifying mill system) is a compact fine powder grinding mill that combines grinding and precise classification in one closed-loop housing. Feed material is crushed by a high-speed rotor (impact and shear), then instantly carried into an internal air classifier that separates fine powder from coarse particles in real time.

How grinding and air classification work together

Inside the air classifier mill:

- The rotor or pins grind the material into fine powder (impact + attrition).

- A strong airflow lifts the particles into the integrated air classifier.

- Fine particles that meet the target micron size pass through as product.

- Oversized particles are rejected by the classifier and thrown back to the grinding zone until they’re fine enough.

This built-in loop gives you tight particle size distribution (PSD) without external sieves or extra equipment, very similar in concept to other modern powder classification systems.

Controlling particle size with the integrated classifier

You control cut size and PSD mainly through:

- Classifier wheel speed – higher speed = finer cut, lower speed = coarser product.

- Air volume / airflow – more airflow helps carry finer particles; less airflow keeps coarser powder in the mill.

- Rotor speed – higher speed improves fineness but increases energy use and wear.

With the right settings, an air classifier mill can consistently hit d90 in the 10–150 μm range with a clean, narrow PSD, ideal for many industrial powders.

Ideal applications for air classifier mills

This kind of industrial powder grinder works best when you need fine to medium-fine powder, stable quality, and a relatively high throughput in a single pass. Common uses:

- Chemicals & pigments – additives, resins, inorganic pigments, dyestuffs.

- Food & spices – sugar, spices, proteins, cocoa, food additives (with food-grade design).

- Minerals – soft to medium-hard minerals where ultra-ultrafine is not required.

- Pharma & cosmetics – excipients and non-API ingredients in GMP-style configurations.

It’s especially useful where you want one compact, closed, dust-controlled system instead of separate mill + external classifier.

Fineness range, throughput, and energy use

Typical numbers (varies by material and model):

- Fineness range: about 20–150 μm, sometimes finer on soft or brittle materials.

- Throughput: from a few kg/h (lab and pilot) up to several tons per hour in a full fine powder production line.

- Energy use: generally more energy-efficient than jet mills at the same fineness, but more energy-intensive than simple hammer or pin mills.

You’re basically trading some power consumption for better precision and fewer process steps.

When to choose an air classifier mill vs a jet mill

Go for an air classifier mill when:

- You need fine, but not extreme ultrafine powder (say, >5–10 μm).

- You want lower energy cost and higher capacity than a jet mill at similar fineness.

- Your product can handle some mechanical impact and moderate heat.

- You want integrated classification in a single, compact unit with simpler operation.

Choose a jet mill grinder instead when:

- You need ultrafine or submicron powder.

- The material is very heat-sensitive or needs ultra-high purity with minimal metal contact.

For many global manufacturers in chemicals, food, and minerals, an air classifier mill hits the sweet spot between precision, cost, and throughput in everyday fine powder processing.

Ring Roller Mill for Mineral Powder

Structure & Working Principle

A fine powder grinding mill in ring roller design uses multiple grinding rollers pressing against a rotating grinding ring. Material is fed into the mill, thrown onto the ring by centrifugal force, and crushed repeatedly between roller and ring.

Key parts in a typical ring roller mill:

- Grinding ring + grinding rollers – main fine grinding zone

- Plow or shovel system – lifts material into the grinding area

- High-efficiency classifier – controls final particle size in a closed-circuit grinding system

- Airflow system – carries fine powder out, returns coarse back to the grinding zone

This dry grinding technology gives stable, repeatable micron powder production with tight particle size distribution.

Best Materials for Ring Roller Mills

I mainly use ring roller mills for:

- Calcium carbonate (GCC/PCC)

- Talc, kaolin, barite, dolomite, feldspar

- Quartz and other nonmetallic ores

For large-scale ultrafine mineral powder processing, a ring roller mill is usually more efficient and cost-effective than many other particle size reduction equipment options. You can see how this works in real projects in our non-metallic mineral powder grinding lines.

Fineness Range & Capacity

A modern ring roller ultrafine grinding mill typically delivers:

- Fineness: about D97 10–45 μm, depending on classifier speed and configuration

- Output capacity: from 2–3 t/h on small systems up to 20+ t/h on large industrial powder grinders

That makes it ideal when you need both fine powder and high throughput in one line.

Energy Efficiency & Continuous Stability

For mineral powder grinding, ring roller mills are built for 24/7 continuous duty:

- Lower specific energy use than traditional ball mills at the same fineness

- Stable product quality thanks to precise particle size distribution control

- Less vibration and smaller footprint versus many other superfine powder mill designs

The closed-loop powder milling system also makes dust control and product recovery easier.

Ring Roller Mill vs Ball Mill for Fine Minerals

When I compare ring roller mills to ball mill with classifier systems for fine mineral grinding:

- Energy consumption: ring roller is usually 20–40% more energy-efficient at fine D97 10–20 μm

- Installation space: ring roller mills are more compact

- Maintenance: fewer grinding media, simpler internals than a large ball mill

- Fineness: both can reach fine powder; ring roller tends to give narrower PSD with less oversize

I normally choose a ring roller calcium carbonate grinding mill or talc ultrafine grinding line when:

- The material is nonmetallic, medium-hard or softer

- You need high tonnage + fine powder with stable, predictable operating cost

Vibration Grinding Mill

A vibration grinding mill (also called a vibro mill for fine powder) uses high-frequency vibrations to make the grinding media hit and rub the material thousands of times per minute. This repeated impact and friction quickly break particles down into very fine powder with tight particle size distribution.

How vibration mills grind very fine powder

Inside the chamber, an eccentric motor or vibrator drives the shell at high frequency. The grinding media (usually balls or cylinders) move in short, intense strokes, generating:

- High-frequency impact – direct hits that crush brittle particles.

- Shear and attrition – sliding and rubbing that refine particles to finer sizes.

- Efficient energy transfer – almost all the energy goes into the media and material, not lifting a full charge like a traditional ball mill.

Media types and chamber design

To get stable, repeatable fine powder, I focus a lot on media and chamber engineering:

- Media options

- Ceramic balls (alumina, zirconia): for high-purity, low-contamination powder.

- Steel or alloy media: for hard, abrasive minerals and metals.

- Small-size media (1–10 mm): improves fine and superfine grinding performance.

- Chamber design

- Cylindrical or U-shaped chambers for even distribution of media.

- Multi-chamber layouts to push from coarse to fine in one pass.

- Wear-resistant liners (ceramic or hardened steel) to reduce contamination and extend life.

Suitable materials and target fineness

A vibration mill is a good fit when you need fine to ultrafine powder but don’t want a huge footprint:

- Good materials:

- Nonmetallic minerals (quartz, feldspar, kaolin, calcium carbonate)

- Pigments, ceramics, battery materials, metal powders

- Fragile or brittle chemicals that respond well to impact

- Typical fineness:

- D90 within 10–50 μm in standard setups

- With optimized media and conditions, can push toward sub-10 μm for some materials

Efficiency and footprint advantages

For many customers, the main reasons to choose a vibration grinding mill are:

- High grinding efficiency at relatively low installed power

- Compact footprint, easy to fit into existing powder grinding plants

- Lower media consumption compared to some high-energy mills

- Flexible operation from lab-scale to small and mid-size industrial lines

Because the design is compact, it’s often part of modular fine powder production lines where space is tight but fineness requirements are strict.

When vibration mills outperform traditional mills

Vibration mills can beat conventional ball mills or hammer/pin mills in several cases:

- When you need finer powder than a pin mill or hammer mill can reliably deliver, but don’t want to jump straight to a jet mill.

- When space is limited and a full-size ball mill installation is not realistic.

- For short-run, high-value materials where high energy per kg is acceptable and product quality/purity matter more than bulk throughput.

- For hard, brittle minerals where impact dominates and the material breaks cleanly.

Many users will start with a pin mill and then move to a vibration mill when they need better fineness and narrower PSD; for example, upgrading spice or chemical grinding setups that previously relied only on pin mill grinders.

Ball Mill with Classifier System

A ball mill with classifier system is a classic setup when you need stable, continuous fine and ultrafine powder grinding at industrial scale. It combines a ball mill (for grinding) and an external air classifier (for precise particle size control) into a closed-circuit grinding system.

Closed-circuit ball mill with external classifier

In a closed loop, the process is simple and reliable:

- The ball mill grinds the material into a wide PSD (particle size distribution).

- Ground material goes to the air classifier.

- Fine powder within the target size exits as product.

- Oversize particles are sent back to the ball mill for regrinding.

This recirculation keeps energy focused on the coarse fraction and gives you consistent micron powder production with controlled quality.

How the classifier controls ultrafine powder size

The external ultrafine air classifier is the brain of the system. You control fineness mainly by:

- Classifier wheel speed – higher speed = finer cut size.

- Airflow volume and pressure – tunes separation sharpness and PSD.

- Feed rate – too high and the PSD widens; optimized feed keeps a tight curve.

With proper tuning, you can achieve narrow PSD, cut down oversize, and produce stable ultrafine mineral powder or chemical powders that meet strict spec.

Material compatibility and hardness range

A ball mill classifier system is versatile and handles a wide hardness range:

- Soft to medium-hard: calcium carbonate, talc, barite, kaolin.

- Medium to hard: quartz, feldspar, silica, many inorganic chemicals.

- Custom linings (ceramic, high-chrome alloy, rubber) reduce wear and metal contamination for high-purity powder processing.

If you’re dealing with very abrasive or high-purity minerals like silica or carbon-based materials, pairing the right lining and media with the classifier setup is key—this is exactly what we do in our ultrafine mineral powder processing lines and related projects such as advanced spherical silica micro powder production.

Fineness capability and production scale

Typical performance for a modern industrial powder grinder with ball mill + classifier:

- Fineness range:

- ~ d97 20–250 µm for standard fine powder

- down to ~ d97 5–10 µm with optimized design and classification

- Capacity:

- From a few hundred kg/h (small systems)

- Up to several tens of tons per hour for large powder grinding plants

That makes it a strong choice for continuous, high-throughput powder production lines in minerals, chemicals, and fillers.

When a ball mill classifier system makes the most sense

I usually recommend a ball mill with classifier when:

- You need high capacity and stable long-term production.

- Your product fineness is in the fine to low-ultrafine range (not nanometer scale).

- You’re processing abrasive or hard minerals where roller mills or pin mills wear out too fast.

- Operating cost, energy efficiency, and maintenance matter more than having the very finest possible powder from a jet mill.

- You want flexible control of PSD without changing the core machine.

If your target is robust, scalable ultrafine mineral powder production with predictable cost and quality, a ball mill + classifier closed-circuit system is often the most practical and profitable solution.

Pin Mill and Hammer Mill for Fine Powder

Pin mills and hammer mills are the go-to workhorses when you need reliable fine or medium-fine powder at a reasonable cost and simple operation.

How Pin Mills and Hammer Mills Grind

Pin mill (impact pin milling):

- Two discs with pins rotate against each other (or against a stationary disc)

- Particles are shattered by high-speed impact between the pins

- Works best on brittle, low-oil materials

- Easy to add a basic classifier or screen for tighter control

Hammer mill (hammer milling):

- Rotating hammers hit the material against a liner or screen

- Size reduction by impact + some shear

- Handles a wider range of feed materials, including slightly moist or fibrous ones

- Screen size sets the approximate final fineness

Key Differences: Pin Mill vs Hammer Mill

| Feature | Pin Mill | Hammer Mill |

|---|---|---|

| Main mechanism | High-speed pin impact | Hammer impact + some shear |

| Typical fineness | Finer (down to ~50–100 µm) | Medium-fine (usually 150–500 µm) |

| Best for | Brittle, crystalline, low-fat | General powders, grains, biomass |

| Shape of particles | More uniform, less coarse tails | Broader distribution, more fines + coarse |

| Heat generation | Higher (fast tip speed) | Moderate |

| Wear risk with abrasives | Higher | Medium |

Best Materials and Industries

Pin mill applications:

- Food & spices: sugar, salt, pepper, chili, dehydrated vegetables

- Chemicals: fertilizers, additives, resins, minor bulk chemicals

- Pharma & cosmetics (non-sterile): excipients, cosmetic fillers

- Recycling: hard plastics, minor additives

Hammer mill applications:

- Food & feed: cereals, maize, soy meal, animal feed, premix

- Biomass: wood chips, fibers, husk, pellets pre-grinding

- Minerals: soft minerals pre-crushing before fine mills

- General chemicals: rough to medium-fine grinding

If you need integrated feeding or upstream processes, it’s easy to combine these mills with dedicated powder feeding equipment in a compact line.

Fineness Limits – Where They Fall Short

In real production, pin and hammer mills normally reach:

- Hammer mill: D90 ≈ 300–600 µm (some designs down to ~150 µm)

- Pin mill: D90 ≈ 80–200 µm, with good settings and right material

They are not enough when you need:

- Ultrafine powder: <30–50 µm, especially <10 µm

- Very narrow PSD (tight particle size distribution)

- High flowability and low dust for advanced polymers or additives

- High-purity and low metal contamination (electronics, pharma)

Upgrading to Ultrafine Grinding Systems

Once your product needs move beyond ~50–80 µm, it’s usually more cost-effective to step up to an ultrafine grinding mill instead of over-driving pin or hammer mills.

Common upgrade routes:

- Air classifier mill (ACM):

- Impact grinding + built-in air classifier

- Good for food, chemicals, and many minerals

- Tight PSD, typically D97 10–75 µm

- Jet mill grinder (spiral or fluidized bed jet mill):

- Uses compressed air or steam, no mechanical media

- Ideal for heat-sensitive, high-purity powder

- D50 can reach 1–5 µm and below

- Ball mill with classifier or ring roller mill:

- Better for mineral ultrafine powder (e.g. CaCO₃, talc, quartz)

- Stable, large-scale, energy-efficient for very fine mineral lines

If you’re already running a pin or hammer mill and need finer, we usually:

- Keep your existing mill as a pre-grinder;

- Add an ultrafine mill + classifier downstream;

- Close the loop with a dust-free grinding system and precise classification.

You can see the kind of integrated fine powder lines I’m talking about in our industrial powder grinder range on the fine powder grinding mill products page.

Comparing Fine Powder Grinding Mill Types

When you’re choosing a fine powder grinding mill, you’re really balancing four things: fineness, PSD control, throughput, and total cost. Below is a straight, practical comparison of the main industrial powder grinder options.

Fineness Range & PSD Control

- Jet mill (spiral / fluidized bed jet mill)

- Fineness: D50 ≈ 1–10 µm, can reach submicron with the right setup

- PSD: Very narrow, excellent control with integrated ultrafine air classifier

- Best when you need ultrafine, high-purity, heat‑sensitive powders

- Air classifier mill (air classifying mill system)

- Fineness: D50 ≈ 5–45 µm

- PSD: Adjustable and fairly narrow via classifier speed & airflow

- Good “all‑rounder” for chemicals, pigments, food, and minerals

- Ring roller mill / Raymond roller grinding mill

- Fineness: Typically 20–400 mesh (≈ 40–75 µm) with fine versions going down into 10 µm range

- PSD: Stable, not as sharp as jet mills

- Ideal for nonmetallic mineral milling like calcium carbonate, talc, quartz

- Ball mill with classifier (closed‑circuit grinding system)

- Fineness: D97 ≈ 5–45 µm (with fine classifiers)

- PSD: Flexible; can be tuned but not as tight as pure jet mills

- Works well for hard, abrasive minerals at medium–large scale

- Vibration grinding mill (vibro mill for fine powder)

- Fineness: Commonly 5–30 µm depending on media and time

- PSD: Good, but more sensitive to operating conditions

- Strong for lab, small‑scale, and specialty powders

- Pin mill grinder / hammer mill for fine grinding

- Fineness: Typically 50–200 mesh (≈ 75–300 µm)

- PSD: Broader; more “medium‑fine” than ultrafine

- Go‑to choice for spices, food additives, bulk chemicals before upgrading to ultrafine systems

If you need even tighter particle size distribution control, pairing mills with a dedicated ultrafine air classifier is often the cleanest solution.

Throughput, Energy Use & Operating Cost

- Jet mills

- Throughput: Low–medium

- Energy: Highest kWh/t

- Opex: High, but unmatched for purity and fineness

- Air classifier mills

- Throughput: Medium

- Energy: Lower than jet mills for the same fineness

- Opex: Balanced; strong choice for continuous fine powder production

- Ring roller mills

- Throughput: Medium–high

- Energy: Very good efficiency for mineral powder production

- Opex: Low per ton, great for large mineral powder grinding lines

- Ball mill + classifier systems

- Throughput: Medium–high

- Energy: Moderate–high

- Opex: Higher wear but flexible and robust, especially with abrasive ores

- Vibration mills

- Throughput: Low–medium

- Energy: Can be efficient at small scale

- Opex: More niche; great when footprint is tight

- Pin & hammer mills

- Throughput: High

- Energy: Low–medium

- Opex: Low, simple maintenance; limited when you need micron powder production

Best Mill Choice by Material & Industry

- Nonmetallic minerals (calcium carbonate, talc, quartz, kaolin)

- Coarse–fine: Ring roller mill

- Fine–ultrafine: Ball mill + classifier, jet mill for top‑end fillers

- Chemicals & pigments

- Fine: Air classifier mill, pin mill

- Ultrafine / high‑value pigments: Jet mill, or air classifier mill with high‑precision classification

- Pharmaceuticals & cosmetics

- Ultrafine APIs & high‑purity powders: Jet mill, GMP‑grade pharmaceutical powder mill

- Excipients and cosmetic powders: Air classifier mill with stainless steel grinding chamber

- Food, spices, additives

- Spices, herbs, sugar, proteins: Hammer mill, pin mill, air classifier mill for finer textures

- Odor‑sensitive or heat‑sensitive ingredients: low‑temperature air classifier mill or jet mill

Quick Comparison Table – Fine Powder Grinding Technologies

| Mill Type | Typical Fineness Range | PSD Control | Throughput | Energy Use | Best For |

|---|---|---|---|---|---|

| Jet mill (spiral / FB) | D50 ≈ 1–10 µm | Very narrow | Low–Medium | High | Ultrafine, high‑purity, heat‑sensitive powders |

| Air classifier mill | D50 ≈ 5–45 µm | Narrow, flexible | Medium | Medium–Low | Chemicals, pigments, food, general fine powder |

| Ring roller mill | ~40–75 µm (down to ~10 µm) | Moderate | Medium–High | Low | Mineral powder processing, fillers, coatings |

| Ball mill + classifier | D97 ≈ 5–45 µm | Moderate–good | Medium–High | Medium–High | Hard minerals, large‑scale ultrafine mineral powder |

| Vibration grinding mill | ≈ 5–30 µm | Moderate–good | Low–Medium | Medium | Specialty and lab‑scale fine particle milling |

| Pin / hammer mill | ≈ 75–300 µm (50–200 mesh) | Broad | High | Low–Medium | Spices, food, bulk chemicals, pre‑grinding |

If you’re handling special ceramics or advanced functional materials, it’s often worth looking at more tailored solutions and case studies, like those for special ceramic powder materials on our fine powder processing insights, before locking in a mill type.

Key Features of a Fine Powder Grinding Mill

A fine powder grinding mill lives or dies on control, stability, and cleanliness. Here’s what I always lock in when we design or choose a system.

Adjustable fineness & precise classification

You need to dial in particle size, not “roughly” hit it.

- Stepless fineness adjustment via classifier speed / airflow

- Stable PSD control for narrow cut (D97, D50, etc.)

- Real-time tuning to handle different recipes and materials

| Feature | What It Gives You |

|---|---|

| Variable classifier speed | Tight control of cut size |

| Adjustable airflow | Balance between fineness and capacity |

| Online PSD monitoring* | Fast response to product drift |

*On advanced systems.

Wear-resistant design & contact materials

Fine grinding is brutal on hardware. I design for long life and clean product.

- Wear-resistant liners & parts (ceramics, special alloys)

- Optional stainless steel contact surfaces for food / pharma

- Optimized mill internals to cut metal contamination and downtime

| Area | Typical Material Options |

|---|---|

| Grinding parts | Alloy steel, carbide, ceramics |

| Liners | High-chrome, alumina, SiC, PU |

| Housing/contact | Carbon steel, stainless steel (304/316) |

Temperature control for heat-sensitive powders

Fine grinding generates heat; many powders can’t take it.

- Controlled air temperature and airflow

- Options for low-temperature / cold grinding

- Protection against melting, oxidation, and caking

| Need | Solution |

|---|---|

| Keep API below Tg/melting | Cold air / chilled circuit |

| Avoid color change in pigments | Short residence, cooler design |

| Prevent sugar/spice caking | Controlled inlet air humidity |

Dust collection, filtration & product recovery

A modern fine powder mill must be clean, safe, and efficient.

- Closed-loop systems to cut dust emissions

- High-efficiency filters and cyclones for powder recovery

- Designed for ATEX / explosion control where needed

| Function | Typical Equipment |

|---|---|

| Primary separation | Cyclone / classifier |

| Fine dust capture | Bag filter / cartridge filter |

| Safety | Explosion vents / isolation |

For example, our dust-free grinding system for mineral and chemical powders integrates high-efficiency filtration and product recovery similar in concept to the systems used in modern Raymond roller grinding setups.

Control systems, automation & data monitoring

If you can’t see it, you can’t control it.

- PLC + HMI for recipe-based operation

- Real-time data on power, pressure, temperature, PSD (optional)

- Remote monitoring and alarms to protect equipment and product

| Control Item | Why It Matters |

|---|---|

| Mill & classifier speed | Direct control of fineness |

| Air volume/pressure | Affects capacity & PSD |

| Power draw | Early warning for overload/issues |

These features are what separate a basic powder pulverizer machine from a truly industrial fine powder grinder that can run stable, safe, and profitable in 24/7 production.

Material Compatibility and Design Options for a Fine Powder Grinding Mill

When I design a fine powder grinding mill system, I start from the material, not the machine. Different powders behave completely differently in the mill, so matching design to material is non‑negotiable.

Handling Abrasive, Sticky, and Fibrous Powders

- Abrasive (quartz, silica, ceramics, some pigments)

- Use hard wear parts (carbide, high‑chrome alloy, engineered ceramics).

- Prefer ring roller mills, ball mills with classifier, or jet mills for longer service life.

- Add wear liners in high‑velocity areas (inlet, outlet, classifier).

- Sticky / Oily (some food, pharma, resin, waxy chemicals)

- Choose low-temperature grinding (jet mill, cooled air classifier mill).

- Smooth internal surfaces to reduce build-up.

- Consider cryogenic grinding or chilled air when sticking is severe.

- Fibrous (herbs, plant fibers, some plastics)

- Use hammer mill or pin mill as pre‑grinder.

- Design rotor and screen/liner to avoid wrapping and clogging.

- Often run in two stages: coarse cut + fine powder grinding mill.

Metal Contamination and High‑Purity Designs

For high‑purity powders (pharma, electronics, high-end pigments, specialty minerals), metal pick-up is a big issue.

- Low‑metal contact design:

- Replace standard steel with ceramic or polymer contact parts where possible.

- Use non-contact classifiers and smooth channels to minimize abrasion.

- Magnetic separation on feed line to catch tramp iron.

- Fully enclosed, dust-free grinding system to avoid external contamination.

For ultra‑clean mineral lines like high-purity calcium carbonate, I usually pair a ring roller mill or ball mill with classifier plus a carefully chosen liner system. For a deeper dive on this type of setup, check the detailed guide to an efficient calcium carbonate grinding mill line on our site: calcium carbonate grinding mill guide.

Choosing Lining Materials: Ceramics, Alloys, Stainless Steel

Use liners to balance wear, purity, and cost:

| Lining Material | Main Benefits | Typical Use Cases |

|---|---|---|

| Ceramic (Al₂O₃, ZrO₂) | Ultra low contamination, high hardness | High-purity minerals, pigments, electronics |

| High-chrome alloy | Strong wear resistance, cost-effective | Abrasive minerals, mining, fillers |

| Stainless steel (304/316) | Corrosion-resistant, food/pharma safe | Food, spice, cosmetic, pharmaceutical powders |

I normally mix and match: for example, ceramic classifier + alloy grinding zone to balance purity and cost.

Moisture, Feed Size, and Pre‑Processing

Material moisture and feed size decide how far we can go in one step.

- Moisture content

- Ideal for dry grinding: usually ≤1–2% for ultrafine, ≤5% for standard fine grinding.

- Above that, I recommend pre‑drying or a mill design that tolerates higher moisture (some air classifier mills or turbo mills as in this turbo dry grinding mill example).

- Feed size

- Jet mill / air classifier mill: typically <3–5 mm.

- Ring roller / ball mill: can take coarser feeds, but a crusher is still often used.

- Oversized feed causes high wear, poor fineness, and unstable operation.

Custom Configurations for Special Powder Requirements

For global customers with specific needs, I typically customize the fine powder grinding mill system around:

- Special atmosphere: nitrogen or inert gas for explosive or oxidation‑sensitive powders.

- Temperature control: chilled air, water jackets, or split-stage grinding for heat‑sensitive materials.

- Integrated steps: pre‑crushing, drying, ultrafine classification, and dust collection in one closed-loop powder milling system.

- Module size: from lab‑scale powder mills and pilot systems to full industrial powder grinding lines with automation and data logging.

Every powder has its own “personality.” The right combination of mill type, lining, and system design is how we keep your fine powder grinding mill running stable, clean, and profitable.

Industrial Applications of Fine Powder Grinding Mills

Fine powder grinding mills sit at the core of modern powder processing. In my plants, we treat them as strategic equipment, not just “machines,” because the right fine powder grinding mill can decide whether a product passes spec or fails.

Key Industries Using Fine & Ultrafine Grinding

You’ll see industrial powder grinders and ultrafine grinding mills heavily used in:

- Mineral and mining – calcium carbonate, talc, quartz, kaolin, barite, nonmetallic ores.

- Chemicals & pigments – additives, catalysts, carbon black, titanium dioxide, color pigments.

- Pharmaceuticals & cosmetics – APIs, excipients, cosmetic powders, fillers.

- Food, spices, and additives – spices, herbs, sweeteners, functional powders, baking soda.

- Battery, ceramics & advanced materials – Li-ion materials, ceramic powders, metal oxides.

We design complete fine powder production lines for these sectors, often integrating mills with high-precision centrifugal classifiers when customers need very narrow particle size distribution.

What “Fine” and “Ultrafine” Mean by Industry

“Fine” and “ultrafine” are not the same for everyone:

- Minerals:

- Fine: D97 20–45 µm

- Ultrafine: D97 5–10 µm (for high-end fillers and coatings)

- Chemicals & pigments:

- Fine: D50 10–30 µm

- Ultrafine: D50 1–5 µm (for color strength, reactivity)

- Pharma & cosmetics:

- Fine: D90 < 100 µm

- Ultrafine: D90 < 10–20 µm, often with very narrow PSD for bioavailability and feel

- Food & spices:

- Fine: 80–200 mesh (≈75–180 µm)

- Ultrafine: 300+ mesh (≤50 µm) for instant solubility or smooth mouthfeel

Typical Performance Targets by Application

When I design or select an industrial fine powder processing system, these are the main targets we lock in:

- Mineral powders

- Stable D97 10–20 µm for fillers

- High whiteness, low contamination

- Low kWh/t for large capacities

- Chemicals & pigments

- Tight PSD for controlled reactivity and color strength

- No oversize particles that affect dispersion

- Clean operation and minimal metal contamination

- Pharma & cosmetics

- Consistent PSD batch to batch

- Low temperature rise for heat-sensitive APIs

- GMP-ready, easy cleaning, full traceability

- Food & spices

- Controlled fineness for flavor release and texture

- Food-grade design, easy washdown

- Odor and cross-contamination control (especially in multi-product plants)

In all these industries, a well-chosen fine powder grinding mill is really about repeatability: hitting the same particle size distribution every shift, at the lowest energy and operating cost you can get.

Mineral Powder Processing and Mining

Fine grinding of calcium carbonate, talc, quartz, and kaolin

In mineral processing, a fine powder grinding mill is the core of any serious production line. I use ring roller mills, ball mill–classifier systems, and jet mills to grind:

- Calcium carbonate (GCC/PCC) down to D97 5–20 μm for standard fillers, and even 2–3 μm for high-end coatings.

- Talc into ultrafine, lamellar powder for plastics, cosmetics, and paper.

- Quartz into fine silica powder for engineered stone, glass, and functional fillers.

- Kaolin into controlled PSD powders for ceramics, paper coating, and paints.

The aim is always stable particle size distribution, clean surfaces, and consistent bulk density.

Ultrafine mineral powder for fillers, coatings, and plastics

For fillers, coatings, and plastics, “fine” is rarely enough. You usually need:

- Ultrafine mineral powders in the 2–20 μm range with narrow PSD.

- High whiteness and purity for architectural coatings and masterbatch.

- Stable rheology so your slurry, paint, or compound runs smoothly in production.

For example, a high-end calcium carbonate grinding line will combine a ring roller mill with a high-precision air classifier to deliver a stable D50 and tight top cut, ideal for plastics and powder coatings. If you’re working with advanced ceramics, the requirements get even tighter, similar to what’s needed for high-purity alumina ceramic powders in battery and electronic applications, as shown in this overview of alumina ceramic powder properties and applications.

Matching mineral hardness to the right grinding mill

Choosing the right ultrafine grinding mill depends heavily on mineral hardness and abrasiveness:

- Soft to medium (talc, kaolin, calcite)

- Ring roller mill / Raymond-type mill

- Air classifier mill

- Ball mill with classifier for very fine GCC

- Medium-hard (dolomite, barite)

- Ring roller mill

- Ball mill + classifier for higher capacity

- Hard and abrasive (quartz, silica, feldspar)

- Ball mill with classifier

- Jet mill for high purity and very fine cut

I always match Mohs hardness, required fineness, and purity level before recommending a mill.

Case-style examples of mineral powder production lines

To keep it concrete, here are typical setups I deliver:

- Calcium carbonate grinding line (coatings/plastics)

- Pre-crushing → ring roller mill → dynamic air classifier → dust collection → silo

- Output: 3–20 μm GCC, 3–20 t/h, energy-optimized and fully automated.

- Talc ultrafine grinding line (plastic & cosmetic grade)

- Hammer pre-mill → jet mill grinder or air classifier mill → ultrafine air classifier

- Focus: lamellar particle shape, very low contamination, stable D97 10 μm or finer.

- Quartz powder milling line (engineered stone & fillers)

- Jaw crusher → ball mill with classifier system → high-efficiency dust collection

- Designed for high hardness, low iron contamination, and tight PSD.

- Kaolin processing line (paper & ceramics)

- Calcination (if needed) → fine grinding → classification → surface modification

- Often integrated with powder coating and surface modification systems like a honeycomb mill coating machine to boost compatibility in polymers and paints.

In all these mineral powder grinding lines, my fine powder grinding mill setups are built for stable PSD, low energy per ton, and clean, dust-controlled operation, so you can scale without losing quality.

Chemical and Pigment Fine Powder Grinding

For chemical powders and pigments, a fine powder grinding mill isn’t optional – it’s how you lock in performance, color strength, and stability.

Fine powder grinding for chemicals and specialty additives

In chemical production, I use fine and ultrafine grinding to:

- Turn flakes, granules, or crystals into micron and submicron powders

- Improve mixing, dispersion, and reaction speed

- Achieve consistent bulk density and flow, which makes dosing and packaging more reliable

A modern industrial powder grinder or powder pulverizer machine lets you run stable, repeatable batches instead of fighting variable quality every shift.

Pigment dispersion and color strength

With pigments, particle size and distribution decide:

- Color strength and tinting power

- Gloss, opacity, and coverage

- Sedimentation and flocculation behavior in liquids

Using an ultrafine grinding mill with tight particle size distribution control gives you:

- Smaller, cleaner particles → higher chroma and stronger color

- Narrow PSD → better dispersion and less settling in paints, inks, and plastics

- More consistent batches → easier color matching across production runs

Controlling PSD for reactivity and stability

For chemicals and specialty additives, the PSD directly affects:

- Reactivity and dissolution rate (finer = faster)

- Chemical stability and shelf life

- Caking, dusting, and flow in handling systems

That’s why I pair grinding with precise powder classification (often with an air classifier mill or external classifier). By tuning classifier speed and airflow, we keep powders:

- In the target micron range

- With a tight PSD that avoids too many fines (dust, caking) or oversize (poor performance)

For a deeper look at how an integrated classifier manages PSD in one pass, I’d point you to

Pharmaceutical and cosmetic powder milling

For pharma and beauty powders, a fine powder grinding mill isn’t “nice to have” – it decides if your product actually works.

Ultrafine grinding of APIs and excipients

For active pharmaceutical ingredients (APIs) and functional excipients, we usually target micron and sub‑micron sizes:

- APIs: often D90 ≤ 10 μm, sometimes down to 1–5 μm with jet mills or air classifier mills

- Excipients (lactose, MCC, starch, talc): controlled in the 10–100 μm range depending on dosage form

- Cosmetic powders (foundations, sunscreens, pigments): soft-focus feel and coverage typically need 5–30 μm, sometimes ultrafine TiO₂ or ZnO below 1 μm

A well-designed ultrafine grinding mill or air classifier mill lets us hit these ranges repeatably, keep PSD tight, and minimize oversized particles that ruin flow and mouthfeel or cause dosing issues.

Particle size, bioavailability, and absorption

Particle size directly affects dissolution rate, bioavailability, and onset of action:

- Smaller particles → larger surface area → faster dissolution

- Narrow PSD → more predictable absorption and dosing

- Poorly soluble APIs often need micronization to hit target exposure

- Inhalation and nasal products demand extremely tight cut points in the 1–5 μm range

This is why we always combine fine powder grinding with precise classification; an integrated air classifier mill system or ball mill with classifier gives us the control needed for regulated markets.

Hygienic, GMP-friendly grinding systems

For pharmaceutical and cosmetic plants, our powder pulverizer machines are built around GMP and hygiene:

- Smooth, crevice-free stainless steel grinding chambers (SS304/SS316L)

- Tool-free access for fast cleaning and changeover

- Validatable CIP/SIP options, full documentation, and material traceability

- Closed-loop powder milling systems with dust-tight design to protect both operator and product

- Full integration with batch records, recipe control, and data logging for audits

If you’re looking at combined grinding and classification, a GMP air classifier mill with hygienic design is often the most flexible choice; you can see sample setups in our air classifier mill solutions.

Milling heat-sensitive and explosive powders

Many APIs, vitamins, and cosmetic actives are heat-sensitive, oxygen-sensitive, or dust-explosive. We handle this at the design level:

- Low temperature grinding mills (jet mills, high-efficiency pulverizers with chilled air or nitrogen)

- Inert gas milling (N₂) for oxygen-sensitive or explosive powders

- Short residence time and optimized airflow to avoid thermal degradation

- ATEX-ready designs with explosion venting, suppression, and grounding

- Strict dust control and filtration for safe, clean operation

In practice, we often combine jet mill grinders or fluidized bed jet mills with ultrafine air classification to get high-purity, low-temperature grinding that meets both regulatory and performance demands.

Food, Spice, and Additive Grinding with a Fine Powder Grinding Mill

When we grind food, spices, and additives, the goal isn’t just “small” – it’s consistent, controllable fine powder that keeps flavor, flow, and safety in check.

Fine grinding for spices, herbs, and flavorings

With the right fine powder grinding mill or industrial powder grinder, we can:

- Take spices, herbs, sugar, salt, proteins, and flavorings down to fine and medium‑fine powder

- Lock in aroma by short residence time and, if needed, low‑temperature grinding

- Improve mixing and dosing in seasonings, instant foods, bakery mixes, and beverages

Pin mills, hammer mills for fine grinding, and air classifier mills are the most common choices in food powder processing.

Texture and mouthfeel control via particle size

Particle size directly decides:

- Taste and mouthfeel – gritty vs smooth (e.g., drink powders, sauces, bakery fillings)

- Dissolution rate – how fast powders disperse in water, milk, or oil

- Dusting and caking – a tight particle size distribution (PSD) reduces segregation and improves stability

We use precise particle size distribution control and classification to match the target texture for each product.

Food-grade materials and hygienic design

For food and spice grinding, the system has to be food-safe first:

- Stainless steel grinding chambers and contact parts

- Smooth, crevice‑free design for easy cleaning and sanitation

- Options for GMP‑style layouts, metal detection, and sieving

- Fully sealed, dust‑free grinding systems to protect operators and product

Our engineering approach in industrial fine powder processing is similar to what we apply in high-purity sectors like specialty carbon black and nonmetallic minerals; you can see that same process discipline in our work on non-metallic mineral grinding lines.

Managing odor, cross-contamination, and cleaning

Spices and flavorings are strong and sticky – if you don’t manage them well, they contaminate everything:

- Dedicated lines or fast-change designs for allergens and strong-smelling spices

- Tool‑free access to grinding zones for quick dry and wet cleaning

- CIP/SIP options on closed-loop powder milling systems where required

- Strong dust collection and filtration to capture fine aromatic particles and keep the plant clean

In short, a well-designed food-grade fine powder grinding mill gives you consistent flavor, clean operation, safe materials, and easy changeover across your spice and additive portfolio.

How to Choose the Right Fine Powder Grinding Mill

Choosing a fine powder grinding mill is a business decision, not just a technical one. I always start from your real production needs, then match the machine to that—never the other way around.

1. Clarify Your Production Goals First

Before looking at any mill, lock in these basics:

- Target fineness & PSD

- What particle size do you really need? (e.g. D97 10 μm, D50 20 μm)

- How narrow does the particle size distribution (PSD) need to be?

- Material characteristics

- Hardness (Mohs scale), abrasiveness

- Heat sensitivity, melting/decomposition point

- Tendency to stick, cake, or absorb moisture

- Purity requirements (metal-free, low contamination, etc.)

- Production mode

- Batch vs continuous

- Required throughput (kg/h or t/h)

- Space limits, power supply, and local labor costs

2. Step‑by‑Step Approach to Mill Selection

Use this simple sequence to shortlist the right fine powder grinding mill or ultrafine grinding mill:

- Filter by fineness range

- Coarse–medium fine (80–200 mesh): hammer mill, pin mill

- Fine (200–1250 mesh): ring roller mill, air classifier mill

- Ultrafine (<10 μm): jet mill, ball mill + classifier, vibration mill

- Match to material type

- Minerals (CaCO₃, talc, quartz) → ring roller mill, ball mill + classifier, or dedicated calcium carbonate grinding lines

- Heat‑sensitive / high‑purity → jet mill, air classifier mill

- Chemicals / pigments → air classifier mill, ball mill + classifier

- Food / spices → pin mill, hammer mill, food‑grade air classifier mill

- Check operating cost

- Power consumption (kWh/t)

- Wear parts cost (liners, nozzles, rollers, media)

- Downtime, cleaning time, changeover time

- Confirm system design

- Need closed‑loop, dust‑free operation?

- Need low‑temperature or inert gas grinding (e.g. for explosive or reactive powders)?

- Need full automation and data logging?

3. Common Mistakes to Avoid

I see companies lose money on fine powder grinding because of the same issues:

- Over‑spec’ing fineness

Ordering a jet mill when a ring roller mill or air classifier mill already meets the spec. You pay more for no real benefit. - Ignoring PSD, only looking at “mesh”

Two powders at the same “mesh” can perform very differently if the PSD is wide. Always ask for D10/D50/D90 or D97. - Skipping testing and trials

Buying on brochure data only. Lab or pilot trials on your actual material will tell you what fineness, capacity, and energy use you can really expect. - Underestimating maintenance

Cheap upfront, expensive later. Abrasive minerals on soft liners, or complex mills with no local service, quickly kill ROI. - No plan for dust and safety

Fine powder means explosion risk and strict dust control. Especially with metals and NdFeB-type powders, safe design and proper air jet milling precautions are non‑negotiable.

4. Quick Selection Snapshot

| Key Factor | What You Decide | Impact on Mill Choice |

|---|---|---|

| Fineness target | Mesh / μm + PSD width | Coarse → hammer/pin; Fine → roller/ACM; Ultra → jet/ball+classifier |

| Material behavior | Hard, soft, sticky, heat‑sensitive | Drives need for cooling, special liners, or jet mill |

| Capacity requirement | kg/h or t/h | Larger lines favor energy‑efficient roller or ball mill systems |

| Purity & hygiene | Metal‑free, GMP, food‑grade | Requires stainless steel, ceramic liners, easy‑clean designs |

| Budget & energy cost | CAPEX + OPEX targets | Decide between high‑investment/low OPEX vs lower‑cost/simple systems |

If you define these points clearly, selecting the right fine powder grinding mill becomes a straightforward, numbers‑driven choice instead of guesswork.

Match Mill Type to Material Properties

When you choose a fine powder grinding mill, the material always comes first. If you ignore the basic material properties, you’ll fight with low capacity, wear problems, and unstable product quality.

Hardness, Abrasiveness, and Friability

- Hard, abrasive minerals (quartz, feldspar, some ores):

- Better with ring roller mills, ball mill + classifier systems, or other robust mineral mills.

- Avoid light-duty pin/hammer mills – wear parts will disappear fast.

- Soft, friable materials (talc, kaolin, many food powders):

- Run well in air classifier mills, pin mills, or a Raymond / ring roller mill at moderate energy.

- Always match liner and media material (steel, ceramic, PU) to abrasiveness to control wear and contamination.

Moisture, Caking, and Stickiness

- High moisture or sticky feed tends to cake inside fine mills, choke classifiers, and form deposits.

- For these materials:

- Pre-drying or dehumidification is usually mandatory.

- Use mills with strong airflow, good internal wash-out design, and easy access for cleaning (e.g. air classifier mill or hammer mill for pre-grind).

- For fibrous or gummy products (some food, polymers), consider coarser pre-grind, cryogenic milling, or a different process route.

Heat Sensitivity and Melting Point

- Heat-sensitive powders (pharma APIs, some plastics, waxy food ingredients, special chemicals):

- Prefer jet mills (spiral or fluidized bed), which naturally run at lower grinding temperatures.

- Or use vibration mills and air classifier mills with controlled airflow and optional cooling.

- If the material softens, melts, or degrades under friction heat, keep tip speeds controlled, maximize cooling air, and consider low-temperature designs or cryogenic options. You can see which materials suit jet milling best in this overview of materials suitable for jet mill pulverizers: Which materials are most suitable for grinding using a jet mill pulverizers?.

Purity and Contamination Risks

- High-purity applications (pharma, battery materials, electronics, high-end pigments):

- Use ceramic-lined or stainless-steel grinding chambers, and avoid unnecessary metal contact.

- Jet mills and certain air classifier mills can be built as low-contamination or metal-free systems.

- For standard industrial minerals and chemicals, carbon steel may be fine, but for white or high-value powders, we typically specify:

- Stainless steel contact parts or

- Ceramic liners/media to control off-color and metal pickup.

In my own projects, I always start mill selection by mapping these four factors against the fineness target. Once we know hardness, moisture, heat sensitivity, and purity demands, the right fine powder grinding mill shortlists itself.

Define Fineness and Capacity Requirements for a Fine Powder Grinding Mill

Before you pick any fine powder grinding mill or ultrafine grinding mill, you need to lock in fineness and capacity. If these are vague, you will overspend, under-produce, or both.

1. Define Target Particle Size & PSD Bandwidth

Be clear on what “fine” actually means for your product:

| Parameter | What to Define | Typical Range* |

|---|---|---|

| D50 (median size) | Core fineness target | 0.5–50 μm |

| D90 / D97 | Max size limit (oversize control) | 1–80 μm |

| PSD bandwidth (narrow/broad) | How tight you need the distribution | Narrow for pharma, pigments |

| Measurement method | Laser, sieve, etc. | Match your customer’s method |

*Just examples – you set this based on your industry.

Key points:

- Narrow PSD = better performance (reactivity, flow, gloss, bioavailability) but higher cost.

- Broader PSD = cheaper, higher throughput, but less uniform product behavior.

2. Batch vs Continuous Production

Decide how you actually run:

- Batch grinding

- Good for: small lots, frequent recipe changes, R&D, tolling.

- Pros: flexible, easier to switch products.

- Cons: more handling, higher labor per kg.

- Continuous grinding

- Good for: stable recipes, large orders, 24/7 production.

- Pros: lower unit cost, easier automation, stable quality.

- Cons: higher upfront cost, more planning, harder to clean between products.

3. Short-Term Projects vs Long-Term High-Volume Lines

Look at your time horizon:

| Scenario | What to Focus On |

|---|---|

| Short-term / contract / pilot projects | Lower capex, flexible mill, fast changeover |

| Long-term, high-volume line | Energy efficiency, durability, automation, large capacity |

For short-term:

- Smaller lab or pilot mills make sense first.

- You can validate fineness and PSD, then scale up.

For long-term:

- Design around your 5-year volume, not this month’s order.

- Overspec a bit on capacity to avoid a bottleneck.

4. How Fineness & Capacity Impact Total Cost

Finer and faster is never free. The tighter the spec, the more you pay per ton.

- Cost drivers of finer grinding

- More energy per kg

- Higher wear on parts (liners, nozzles, classifier)

- More complex classification (ultrafine air classifier, multi-stage systems)

- Possible cooling / cryogenic options for heat-sensitive materials

- Cost drivers of higher capacity

- Larger equipment and motors

- Bigger dust collection and product handling

- Stronger foundations, more space, higher installation cost

Simple rule:

- Don’t specify “ultrafine” if “fine” already meets product performance.

- Don’t size capacity only for peak demand – but also don’t buy a mill you outgrow in 6 months.

If you’re targeting sub-10 μm or ultrafine ranges at industrial scale, consider high-efficiency systems like a fluidized bed opposed air jet mill that can deliver tight PSD and reasonable energy use in one integrated setup: fluidized bed jet mill solutions.

Budget, Energy, and Operating Costs for a Fine Powder Grinding Mill

When I choose a fine powder grinding mill or ultrafine grinding mill, I don’t just look at the price tag. I look at what it will cost me over 5–10 years of production.

Initial Price vs Lifecycle Cost

- Low initial cost, higher running cost

- Pin mill, hammer mill, simple powder pulverizer machines

- Good for starter projects or small batches

- Higher initial cost, lower lifecycle cost

- Jet mill grinder, air classifier mill, ring roller mill, ball mill with classifier

- Better for high-volume, stable production

I always factor in: power usage, spare parts, downtime, product yield, and labor. Often a “cheap” industrial powder grinder turns out expensive when you calculate waste and stoppages.

Energy Consumption and Efficiency

Different mill types have very different energy profiles:

- Most energy-efficient for very fine & ultrafine

- Air classifier mill, ring roller mill, ball mill + classifier (for large tonnage)

- High energy use but top fineness

- Jet mill (spiral jet mill, fluidized bed jet mill), best when you need submicron powder and no contamination

- Medium energy use, medium fineness

- Pin mill, hammer mill – ideal for food, spices, and coarse–fine powders

For more detail on how energy is used inside a jet mill, I often point customers to this breakdown of what a jet mill is and how it works for ultra-fine particle grinding.

Maintenance, Spare Parts, and Downtime Risks

Before I recommend a fine powder grinding mill, I always check:

- Wear parts cost & life

- Grinding rings/rollers, liners, classifier wheels, nozzles, pins, hammers

- Abrasive minerals (quartz, silicon carbide) demand wear-resistant liners (ceramic, special alloys)

- Ease of access

- Can my team change parts fast? Is cleaning simple?

- Downtime risk

- Complex ultrafine systems (jet mill + classifier) need stable air supply and good maintenance

- Vibration grinding mills and ball mill systems need monitoring for bearings and media wear

Planned maintenance is always cheaper than unplanned shutdowns. A stable closed-circuit grinding system with good dust control and access doors quickly pays back in uptime.

Return on Investment (ROI) for Upgrading to Finer Grinding

Upgrading from a basic hammer or pin mill to a high-efficiency pulverizer or ultrafine grinding mill usually pays off if:

- You sell high-value powders (pharma, cosmetics, pigments, specialty chemicals)

- You need tighter particle size distribution control (narrow PSD)

- You can reduce additives, binder, or pigment dosage thanks to better fineness

- You improve reactivity, solubility, or color strength, so your product sells at a higher price

I always run a simple ROI model:

- Extra investment in the new fine powder grinding mill

- Minus energy savings per ton

- Minus reduced waste and rework

- Plus extra profit from higher-quality micron powder production

In most serious industrial lines, a modern, energy-efficient, dust-free grinding system recovers its cost in 1–3 years, especially when moving from coarse grinding to stable ultrafine mineral powder processing or high-end chemical/pigment milling.

Testing, Trials, and Customization for Fine Powder Grinding Mills

Before you lock in a fine powder grinding mill or a full powder production line, I always push for lab-scale and pilot-scale grinding trials. This is where we remove guesswork and prove what the material can actually do.

Lab-Scale & Pilot Grinding Trials

I usually start with:

- Lab-scale tests on a small jet mill, air classifier mill, or ball mill system to map the real behavior of your powder (grindability, tendency to cake, heat sensitivity).

- Pilot-scale trials to validate throughput, stability, and energy consumption before investing in a full industrial powder grinder.

If you’re comparing jet milling vs other options, trials similar to those described in this breakdown of a jet mill vs ball mill in fine powder processing are exactly what I’d recommend.

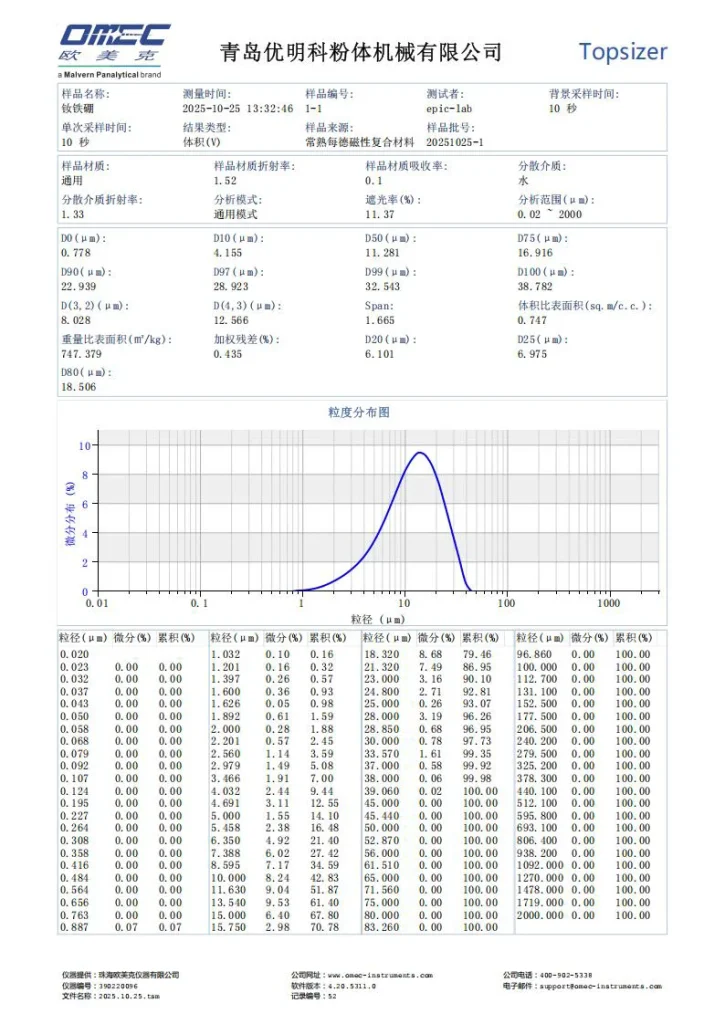

Using Test Reports the Right Way

I don’t treat test reports as paperwork; they’re a decision tool. From a proper report, you should clearly see:

- Achievable fineness (D50, D90, or specific micron range)

- Particle size distribution (PSD) shape and stability over time

- Throughput at target fineness and specific energy (kWh/t)

- Any overheating, sticking, or excessive wear risk

If the trial data doesn’t clearly show fineness vs capacity, we keep testing until it does.

Custom Designs for Special Powders

For tricky materials, I often customize the fine powder grinding mill or system layout:

- High-purity builds with ceramic or stainless liners for battery materials, pharma, and pigments

- Low-temperature or inert gas grinding for heat-sensitive or explosive powders

- Custom air classifier setups for ultra-tight PSD control in ultrafine grinding mill systems

- Specialized feeding, sealing, and cleaning for sticky, fibrous, or high-value powders

This is where a standard powder pulverizer machine turns into a custom fine powder production line.

When to Add Pre‑Crushing, Drying, or Extra Classification

I only add process steps when they clearly improve performance or cost:

- Pre-crushing: If feed >5–10 mm or very hard (quartz, some ores), we pre-crush so the fine mill runs stable and efficient.

- Drying: If moisture causes caking, buildup, or poor classification, an inline dryer or hot-air integration is non-negotiable.

- Extra classification: For premium products (high-end fillers, pigments, battery materials), a separate ultrafine air classifier after the mill tightens PSD and improves product value.

Once testing proves the right flow, I lock that into a customized, closed-loop powder milling system that fits your capacity, energy, and quality targets.

Operating a Fine Powder Grinding Mill

Daily operation basics & process control

When you run a fine powder grinding mill or full powder pulverizer system, keep the routine simple and disciplined:

- Start-up sequence: turn on dust collection → airflow/blower → classifier → mill feed. Reverse the order for shutdown.

- Stable feed rate: keep a steady, controlled feed using a screw feeder or rotary valve to avoid load swings and PSD drift.

- Check material condition: moisture, lumps, and foreign objects will wreck consistency—pre-screen or pre-crush if needed.

- Log key settings: record mill speed, classifier speed, airflow, feed rate, and product PSD so you can repeat good runs.

- Keep everything sealed: tight connections and proper filters keep the system dust-free and protect both product and staff.

If you run an integrated ball mill and air classifier system, like the ones used in many industrial dry grinding lines, lock in your operating “recipe” and stick to it; that’s where consistent micron powder production comes from.

Key process parameters to monitor

To keep your industrial powder grinder in the sweet spot, watch and adjust:

- Product fineness & PSD

- Measure d50/d97 regularly (online or lab).

- Adjust classifier speed and airflow to tighten or shift the curve.

- Airflow & pressure

- Track differential pressure across mill and filter.

- Rising pressure often means filter blinding or build‑up in the system.

- Mill load & power draw

- Use kW/amp draw as a proxy for grinding intensity.

- Sudden changes = feed, moisture, or media issues.

- Temperature

- Outlet temperature affects heat‑sensitive and sticky materials.

- Control via airflow, cooling air, or lower mill speed/feed.

- Dust & product loss

- Check filters, hoppers, and cyclones for leaks and build‑up.

- Good dust collection = higher yield + safer operation.

Signs your grinding system isn’t optimized

If you see any of these, your fine powder grinding mill needs tuning:

- Variable particle size: PSD shifts between batches or shifts in a day.

- Too much oversize or fines: high reject rates or excessive ultra‑fines point to wrong classifier settings or poor air balance.

- High energy per ton: power draw is up, throughput is down—often due to worn parts or unstable feed.

- Frequent blockages or caking: usually moisture, low airflow, or wrong internal design for your material.

- Hot product or mill body: grinding too hard, poor cooling, or pushing capacity beyond its realistic limit.

- Excessive dust or visible leaks: seals, bags, or pipe joints are failing, risking safety and product loss.

When you see two or more of these at once, stop “pushing through” and re-balance the system: airflow, classifier speed, feed rate, and mechanical condition of wear parts.

Maintenance and Reliability Best Practices for a Fine Powder Grinding Mill