- Material: Granulated sugar

- Requirement: 100 mesh

- Production Capacity: 300–450 kg/h

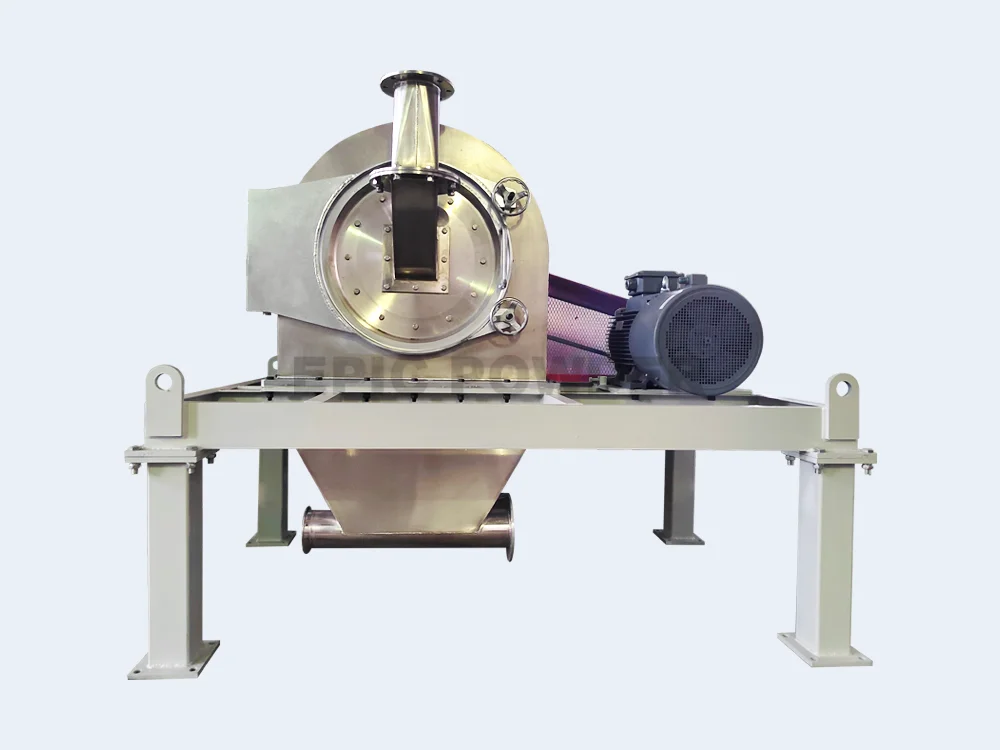

Mexico’s sugar industry provides a steady supply of granulated sugar for food, beverage, and pharmaceutical applications. Several downstream processes require a finer sugar powder with a controlled particle-size distribution around 100 mesh. To meet quality and consistency targets, a dedicated pin mill grinding solution was evaluated for its ability to produce uniform 100 mesh sugar at a stable production rate.

System concept

The project adopts a pin mill grinding configuration integrated with a classifier to achieve precise size reduction and narrow distribution. The flow begins with feeding granulated sugar into the pin mill, where high-speed pins generate impact and shear forces that fracture crystals. The ground material then enters a classifier section, where fine sugar exits, and coarse fractions are returned for regrind. Proper tuning of feed rate, pin configuration, and classifier speed yields a tight 100 mesh target with minimal over- or under-grinding.

Sugar Pin Mill Grinding Project Preliminary Testing

To better serve our customers, EPIC Powder Machinery conducts preliminary testing and verification for every project.

Key design parameters

- Pin mill configuration: double-row pins, high-speed rotor

- Classifier type: centrifugal or cyclone-based with adjustable rotor speed

- Feed moisture: < 1% to prevent agglomeration

- Airflow management: dedusting and product collection via a single-pass or closed-loop system

Operational performance targets

- Particle size distribution: peak around 100 mesh with 5–8% oversize

- Throughput: 300–450 kg/h depending on bulk density and moisture

- Power consumption: minimized via optimized grinding efficiency and classifier tuning

- Dust control: effective filtration to maintain workplace air quality

Estimated process flow

- Pre-drying or conditioning of sugar if moisture exceeds 1%

- Feeding into pin mill at controlled rates

- In-line classification and product discharge

- Optional post-milling stage for tighter distribution if required

Prototype data snapshot

- Target: 100 mesh (150 microns)

- Observed: 95–105 mesh distribution with less than 6% oversize

- Throughput: 320–420 kg/h under standard conditions

- Energy: Specific grinding energy within expected range for pin mill systems

Notes and considerations

Sugar crystallinity and moisture have a strong impact on grinding efficiency and lump formation; maintaining low moisture is essential.

Steel contact surfaces require corrosion resistance and hygiene compliance for food-grade applications.

Cleaning and sanitation procedures should be integrated to prevent cross-contamination in multi-product plants.

Conclusion

The 100 mesh granulated sugar pin mill grinding system offers a compact, efficient solution to produce uniformly distributed 100 mesh sugar at a production rate of 300–450 kg/h. The integrated grinding and classification approach enables tight particle-size control, low fines loss, and acceptable energy usage for a Mexican sugar-processing facility.

Would you like this expanded with a detailed process flow diagram or a data table comparing alternative mills (e.g., pin mill vs. ACM) for the same target?