Modern food and health products processing production line Help you upgrade from a handcrafted workshop to a modern factory

Food and health products are closely related to human life and health, and belong to the health industry as the pharmaceutical industry. Therefore, higher requirements are placed on production machine.

EPIC Powder combines advanced food-grade production systems with engineering expertise to achieve extremely high standards in terms of quality, hygiene, safety and economy. Automatic and intelligent dust-free production line from raw material feeding, grinding and filter to mixing, conveying and stirring. From a handcrafted workshop upgrade to a modern factory.

Project Cases

Taiwan 10-Micron Matcha Classifying Mill Grinding Project

100 mesh granulated sugar pin mill grinding project in Mexico

80 Mesh Rice Husk Impact Mill Production Line in Thailand

300 mesh rice husk grinding and pulverizing line in Malaysia

Milk powder grinding production line of a company in Menggu

Related Posts

We can provide processes and equipment that meet the following performance indicators

Jet Mill

Suitable for grinding materials with high hardness, high purity and high added value.

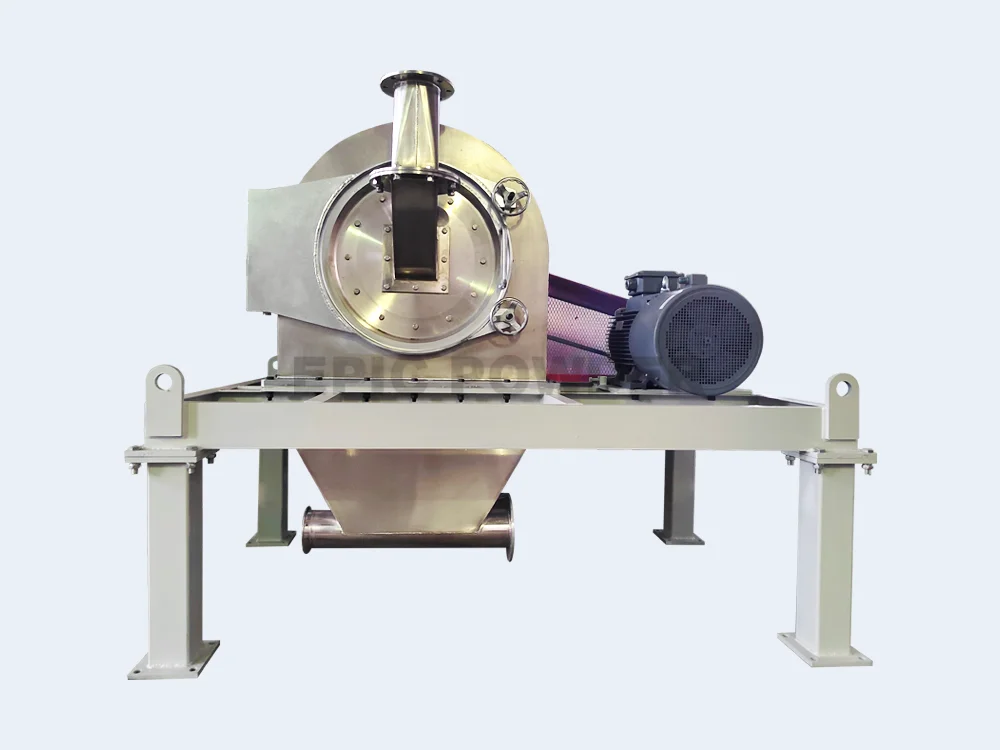

Air Classifying Mill

Integration of grinding and classifying

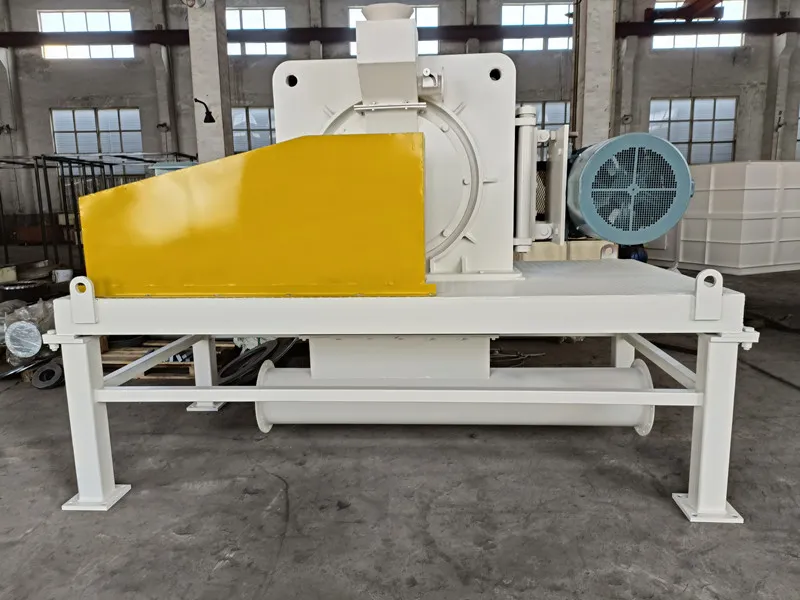

Pin Mill

The material should not exceed Mohs hardness 3.

Depending on the material, the capacity and particle size range will vary. Please contact our engineers to customize the machines more suitable for you.