High tech materials

The rapid development of science and technology has led to the continuous emergence of various new materials, and the emergence of new materials is also promoting the development of technology. Powder can be used as a material, no matter how fine, no matter what. Powder processing technology plays a crucial role in the research and application of materials. EPIC Powder technology aims to provide cutting-edge full process services for the new materials industry with the goals of ultra refinement, ultra purification, specific functions, and safety and environmental protection.

Project Cases

Related Posts

We can provide processes and equipment that meet the following performance indicators

Jet Mill

Suitable for grinding materials with high hardness, high purity and high added value.

Air Classifying Mill

Integration of grinding and classifying

Air Classifier

Clean and environmentally friendly efficient dry method fine classifier

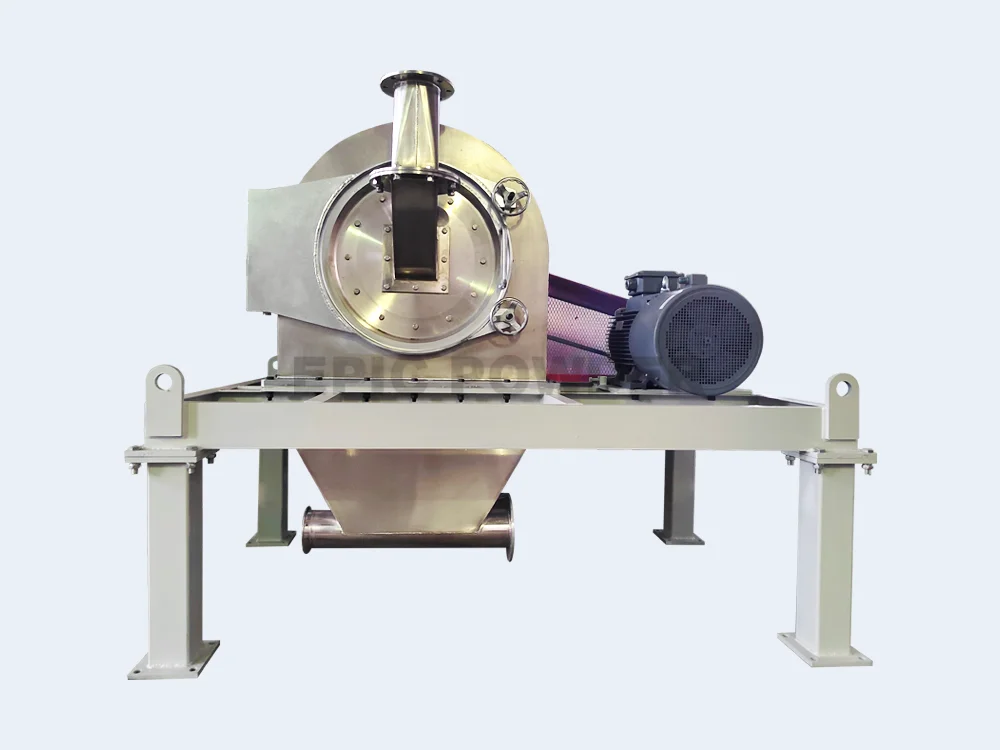

Turbo Mill

A depolymerization reduction pulverization system that integrates encapsulation, modification, and dispersion

- We use independently developed new technologies such as steam kinetic energy grinding, nano turbulence grinding, and supersonic airflow grinding to help customers achieve breakthroughs from micrometer to nanometer scales.

- According to the need for controlling sensitive elements in materials, we use multiple materials to protect key components in contact with materials, greatly ensuring the purity of the materials.

- Tailored solutions based on customer needs to meet specific material functionality requirements, including particle morphology, particle size distribution, dispersion, etc.

- Adopting customized production plans for volatile, corrosive, toxic, and harmful materials greatly reduces the harm of material leakage to human health and the environment.

- The inner lining of the equipment can be made of ceramic materials such as alumina and zirconia according to the production needs, reducing the intake of impurities.

Automation and intelligent control methods are adopted in the powder production process, and measures such as inert gas circulation protection are taken for flammable and explosive materials to ensure safe and controllable production operations.