In the pharmaceutical industry, ultrafine pulverization generally has the following characteristics

- Small particle size, concentrated and uniform distribution, saving raw materials;

- Adiabatic expansion of low-temperature and high-pressure air will absorb the heat generated by the collision of materials, will not overheat locally, and retain the biologically active ingredients of the drug, which is conducive to making the required high-quality products;

- Simple quick disassembly and assembly structure, which is conducive to cleaning and replacing material varieties.

Generally, the size of the particles is about 100 microns, and they are ultra-finely pulverized to several microns. After ultra-micro processing, the surface area of the particles increases, and their dispersibility, adsorption capacity, surface activity, etc. have comprehensive changes. It is of great significance for improving the efficacy and saving the dosage.

Project Cases

2025-10-22

Project Data Taiwan’s premium tea culture drives demand for ultra-fine matcha powders with tight particle-size distributions. Achieving a D50 near 10 μm while preserving aroma, ...

Read More →

2025-10-22

Mexico’s sugar industry provides a steady supply of granulated sugar for food, beverage, and pharmaceutical applications. Several downstream processes require a finer sugar powder with ...

Read More →

2025-10-22

In the past, rice husks were handled in a crude manner, mostly being burned or randomly piled. Burning rice husks emits harmful gases. These include ...

Read More →

2025-10-22

Overview of air classifier mill for rice husk grinding Project Data Material: Rice HuskMoisture Content: <5%Requirement: D50: 300 meshProduction Capacity: 200-250 kg/h Malaysia’s rice husk ...

Read More →

Related Posts

2026-01-20

Fluidized Bed Air Jet Mill: Principle and Structure The Fluidized Bed Air Jet Mill is top-notch in dry powder processing. It combines milling and classification ...

Read More →

2025-12-05

If you’re trying to produce ultrafine, high‑quality powder, choosing the right fine powder grinding mill can make or break your results. Maybe you need a tighter particle size distribution for ...

Read More →

2025-11-24

What Is a Jet Pulverizer Machine? If you need consistent ultra-fine powder without contamination or heat damage, you’re looking for a jet pulverizer machine (also called a fluid ...

Read More →

2025-11-21

What Is Zinc Borate and Why Ultrafine Particle Size Matters Zinc borate is an inorganic compound widely used as a halogen-free flame retardant and smoke suppressant in ...

Read More →

2025-11-20

The rise of porous carbon—especially silicon-carbon composites—is reshaping the future of high-performance battery anodes. But here’s the catch: achieving ultra-fine, contamination-free particle sizes with preserved pore ...

Read More →

2025-11-19

You have an important choice when picking a Jet mill for PE wax. EPIC Powder’s Jet Mill MQW and the AS Spiral Jet Mill are ...

Read More →

2025-11-18

Understanding the Unique Challenges of NdFeB in Air Jet Milling When milling NdFeB (Neodymium-Iron-Boron) powder using an air jet mill, you’re dealing with a material ...

Read More →

2025-11-12

Struggling to pick the right air classifier mill for your operation? You’re not alone. Choosing poorly can lead to costly downtime, inconsistent particle sizes, and wasted energy. ...

Read More →

We can provide processes and equipment that meet the following performance indicators

Jet Mill

Suitable for grinding materials with high hardness, high purity and high added value.

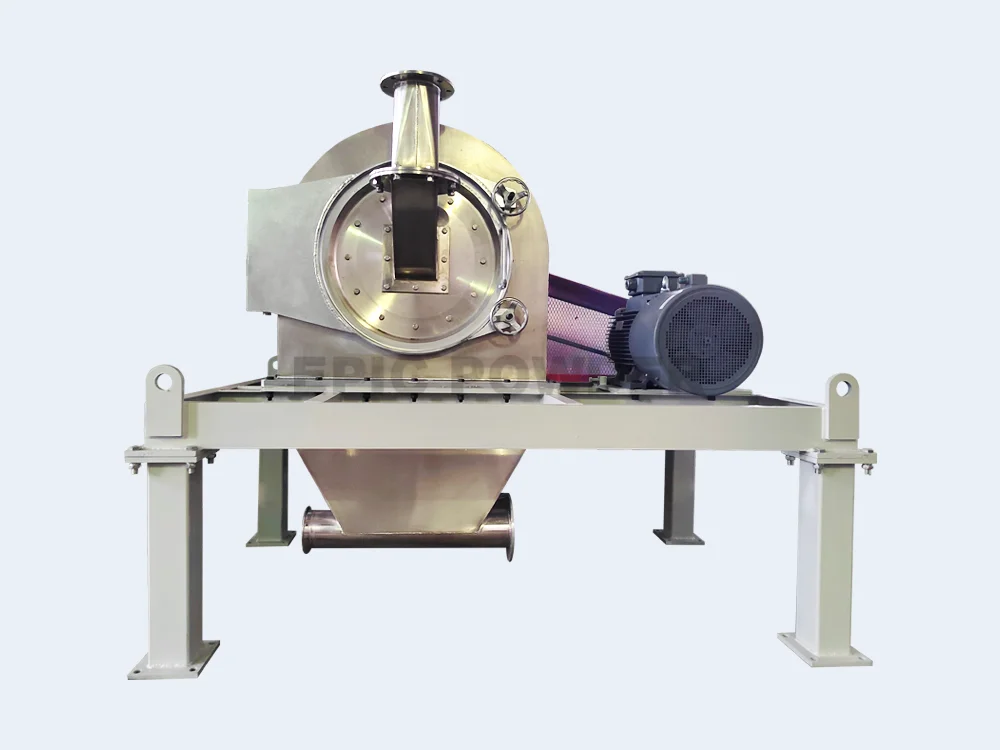

Air Classifying Mill

Integration of grinding and classifying

Spiral Jet Mill

On-line cleaning (CIP) and on-line sterilization(SIP)design is optional.

- Full ceramic protection, increased amount of metal <20ppb.

- The physical shape of the particles is stable, the particle size is uniform, and has good dispersibility, and does not cause agglomeration or precipitation.

- Simple quick disassembly and assembly structure, which is conducive to cleaning and replacing materials.

- Low residue, low pollution, less impurities.

- Jet mill can be used instead of impact mill for production, with higher safety and finer particle size.