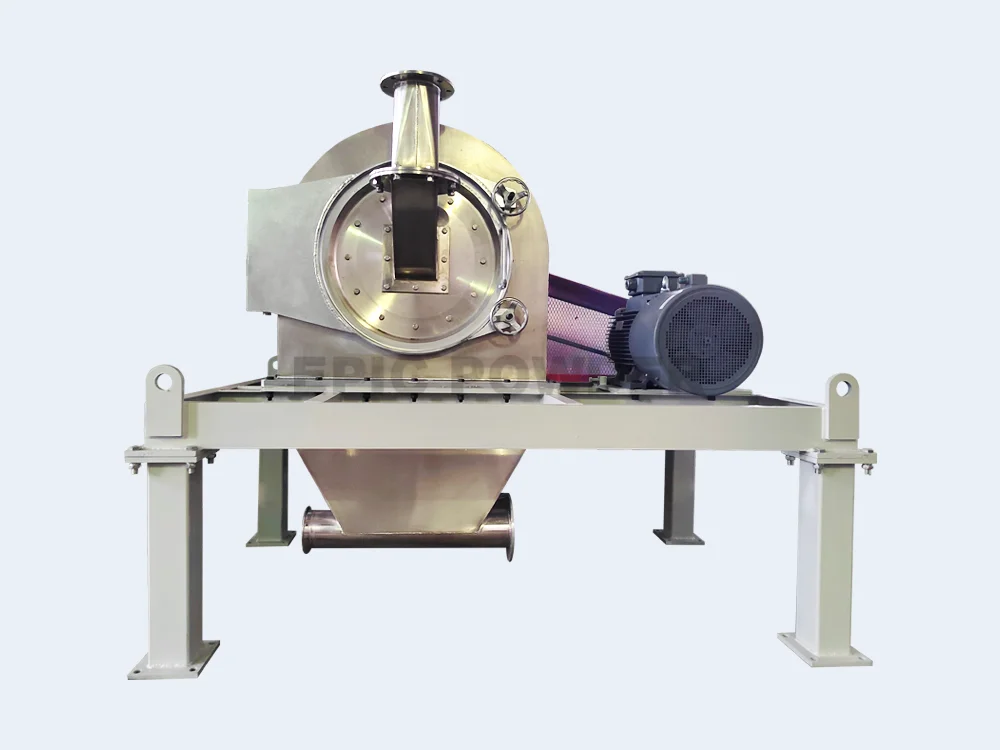

Powder Metallurgy

With the development of industrial modernization in our country, powder metallurgy is widely used in various fields such as military, aerospace, and civilian. Due to the complexity of metallurgical powder production, there are strict requirements for enterprises in terms of grinding technology, particle requirements, safety and explosion prevention, product purity, control of oxygen and moisture, and collection system efficiency. There are also high screening standards for related equipment and processes.

Project Cases

2025-10-22

Project Data Taiwan’s premium tea culture drives demand for ultra-fine matcha powders with tight particle-size distributions. Achieving a D50 near 10 μm while preserving aroma, ...

Read More →

2025-10-22

Mexico’s sugar industry provides a steady supply of granulated sugar for food, beverage, and pharmaceutical applications. Several downstream processes require a finer sugar powder with ...

Read More →

2025-10-22

In the past, rice husks were handled in a crude manner, mostly being burned or randomly piled. Burning rice husks emits harmful gases. These include ...

Read More →

2025-10-22

Overview of air classifier mill for rice husk grinding Project Data Material: Rice HuskMoisture Content: <5%Requirement: D50: 300 meshProduction Capacity: 200-250 kg/h Malaysia’s rice husk ...

Read More →

Related Posts

2026-01-20

Fluidized Bed Air Jet Mill: Principle and Structure The Fluidized Bed Air Jet Mill is top-notch in dry powder processing. It combines milling and classification ...

Read More →

2025-12-05

If you’re trying to produce ultrafine, high‑quality powder, choosing the right fine powder grinding mill can make or break your results. Maybe you need a tighter particle size distribution for ...

Read More →

2025-11-24

What Is a Jet Pulverizer Machine? If you need consistent ultra-fine powder without contamination or heat damage, you’re looking for a jet pulverizer machine (also called a fluid ...

Read More →

2025-11-21

What Is Zinc Borate and Why Ultrafine Particle Size Matters Zinc borate is an inorganic compound widely used as a halogen-free flame retardant and smoke suppressant in ...

Read More →

2025-11-20

The rise of porous carbon—especially silicon-carbon composites—is reshaping the future of high-performance battery anodes. But here’s the catch: achieving ultra-fine, contamination-free particle sizes with preserved pore ...

Read More →

2025-11-19

You have an important choice when picking a Jet mill for PE wax. EPIC Powder’s Jet Mill MQW and the AS Spiral Jet Mill are ...

Read More →

2025-11-18

Understanding the Unique Challenges of NdFeB in Air Jet Milling When milling NdFeB (Neodymium-Iron-Boron) powder using an air jet mill, you’re dealing with a material ...

Read More →

2025-11-12

Struggling to pick the right air classifier mill for your operation? You’re not alone. Choosing poorly can lead to costly downtime, inconsistent particle sizes, and wasted energy. ...

Read More →

We can provide processes and equipment that meet the following performance indicators

- According to the characteristics of the materials, various crushing technologies such as airflow crushing, impact crushing, ball milling crushing, roller pressing crushing, shear crushing, etc. are flexibly used to selectively crush the materials to the micrometer or submicron level.

- For metallurgical powders after grinding or materials after atomization, the particle size distribution between 1 micron and 100 microns can be adjusted by a classifier to achieve different distribution states such as narrow particle size distribution or normal particle size distribution.

- Most metallurgical powders have the characteristics of being flammable and explosive in production processes such as grinding, grading, and conveying. In response to this characteristic, Elpai adopts automated and intelligent monitoring and control methods and inert gas circulation protection systems in the powder process, ensuring the safety and controllability of the production process through multiple measures.