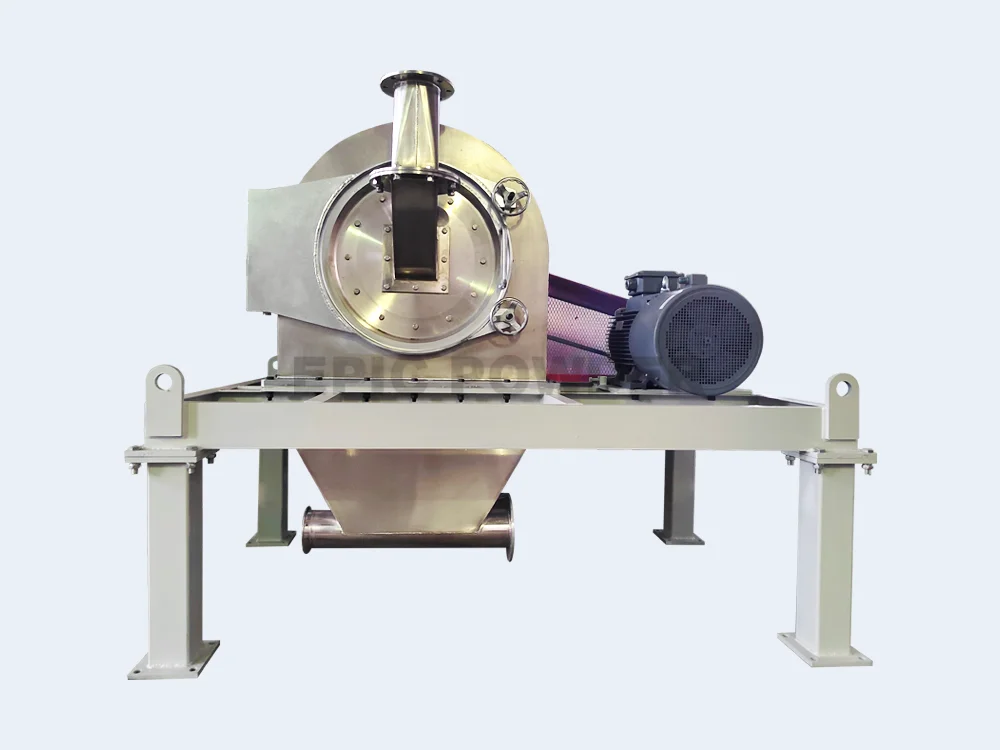

Air Separator

- High fines yield and maximum fines capacity, with a single classifier wheel

- Superfine powders in the range of d97 = 3 µm to d97 = 45 µm

- Classifying wheel supported in bearings on both sides

- Double flooded fine material outlet

- Optimized feed material supply direct to the classifier wheel

- Compact and functional design

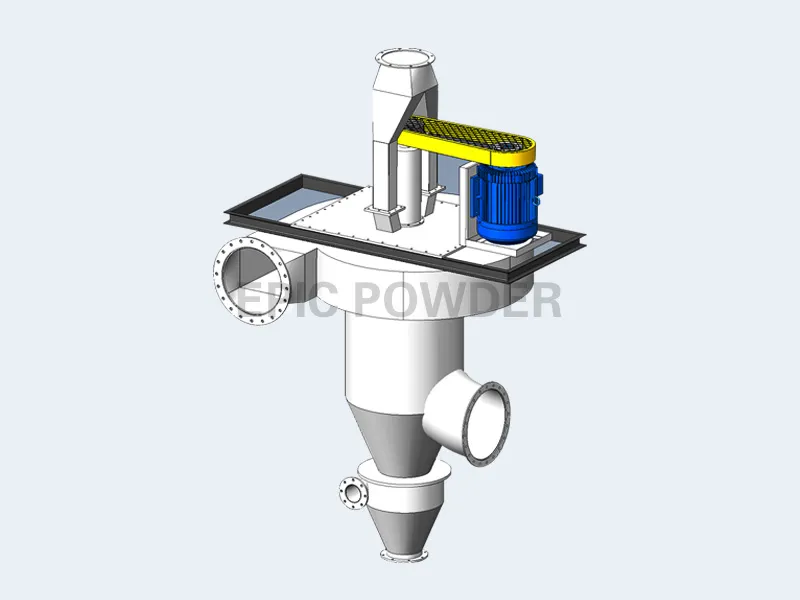

Working Principle

The feeding port of the classifier is at the top of the classifier. The feed enters the classifier from the top inlet under the action of gravity, and then falls onto the centrifugal dispersion disc of the classifying wheel. The material will be evenly dispersed, dispersed to the baffle ring and down into the grading area. Classification air enters the scroll housing, passes the guide vanes, and inwards to the classification wheel. The fine powder is carried by the airflow into the classifying wheel, and then enters the cyclone collector or dust collector with the airflow, while the coarse powder will be repelled by the centrifugal force of the classifying wheel and fall into the lower body of the classifier.

Features And Benefits

- The hierarchical structure design is unique, low pressure, low energy consumption.

- It is very good for apex cutting of ultra-fine products and medium-fine products.

- Applicable to a wide range of particle sizes, the coarsest can reach 200 microns.

- There are different models to meet different output, and the feeding capacity of the largest model can reach 800t/h.

- Wear-resistant design, can handle powder products with extremely high hardness.

- The design of internal air circulation can reduce investment and save floor space.

- It can be combined with a ball mill to form a closed-circuit production system for grinding various materials.

Technical Parameters

| MODEL | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Drive power (kW) | 5.5 | 11 | 15 | 22 | 37 | 45 | 75 | 110 | 132 | 160 | 185 | 220 | 280 | 320 | 380 | 475 | 540 | 630 |

| Air flow rate(m³/h) | 2,800 | 4,700 | 8,600 | 15,200 | 23,400 | 31,000 | 49,000 | 74,000 | 107,000 | 150,000 | 190,000 | 237,000 | 288,000 | 344,000 | 402,000 | 469,000 | 536,000 | 606,000 |

| Fineness D97 (μm) | 8 | 9 | 10 | 13 | 14 | 16 | 18 | 20 | 25 | 27 | 28 | 29 | 31 | 33 | 34 | 35 | 37 | 38 |

| Max. feed (t/h) | 4 | 6.6 | 12.1 | 21.3 | 32.8 | 43 | 68 | 100 | 140 | 210 | 260 | 330 | 400 | 480 | 560 | 650 | 750 | 840 |

Related Products

Project Cases

2025-10-22

Project Data Taiwan’s premium tea culture drives demand for ultra-fine matcha powders with tight particle-size distributions. Achieving a D50 near 10 μm while preserving aroma, ...

Read More →

2025-10-22

Mexico’s sugar industry provides a steady supply of granulated sugar for food, beverage, and pharmaceutical applications. Several downstream processes require a finer sugar powder with ...

Read More →

2025-10-22

In the past, rice husks were handled in a crude manner, mostly being burned or randomly piled. Burning rice husks emits harmful gases. These include ...

Read More →

2025-10-22

Overview of air classifier mill for rice husk grinding Project Data Material: Rice HuskMoisture Content: <5%Requirement: D50: 300 meshProduction Capacity: 200-250 kg/h Malaysia’s rice husk ...

Read More →

Related Posts

2026-01-20

Fluidized Bed Air Jet Mill: Principle and Structure The Fluidized Bed Air Jet Mill is top-notch in dry powder processing. It combines milling and classification ...

Read More →

2025-12-05

If you’re trying to produce ultrafine, high‑quality powder, choosing the right fine powder grinding mill can make or break your results. Maybe you need a tighter particle size distribution for ...

Read More →

2025-11-24

What Is a Jet Pulverizer Machine? If you need consistent ultra-fine powder without contamination or heat damage, you’re looking for a jet pulverizer machine (also called a fluid ...

Read More →

2025-11-21

What Is Zinc Borate and Why Ultrafine Particle Size Matters Zinc borate is an inorganic compound widely used as a halogen-free flame retardant and smoke suppressant in ...

Read More →

2025-11-20

The rise of porous carbon—especially silicon-carbon composites—is reshaping the future of high-performance battery anodes. But here’s the catch: achieving ultra-fine, contamination-free particle sizes with preserved pore ...

Read More →

2025-11-19

You have an important choice when picking a Jet mill for PE wax. EPIC Powder’s Jet Mill MQW and the AS Spiral Jet Mill are ...

Read More →

2025-11-18

Understanding the Unique Challenges of NdFeB in Air Jet Milling When milling NdFeB (Neodymium-Iron-Boron) powder using an air jet mill, you’re dealing with a material ...

Read More →

2025-11-12

Struggling to pick the right air classifier mill for your operation? You’re not alone. Choosing poorly can lead to costly downtime, inconsistent particle sizes, and wasted energy. ...

Read More →