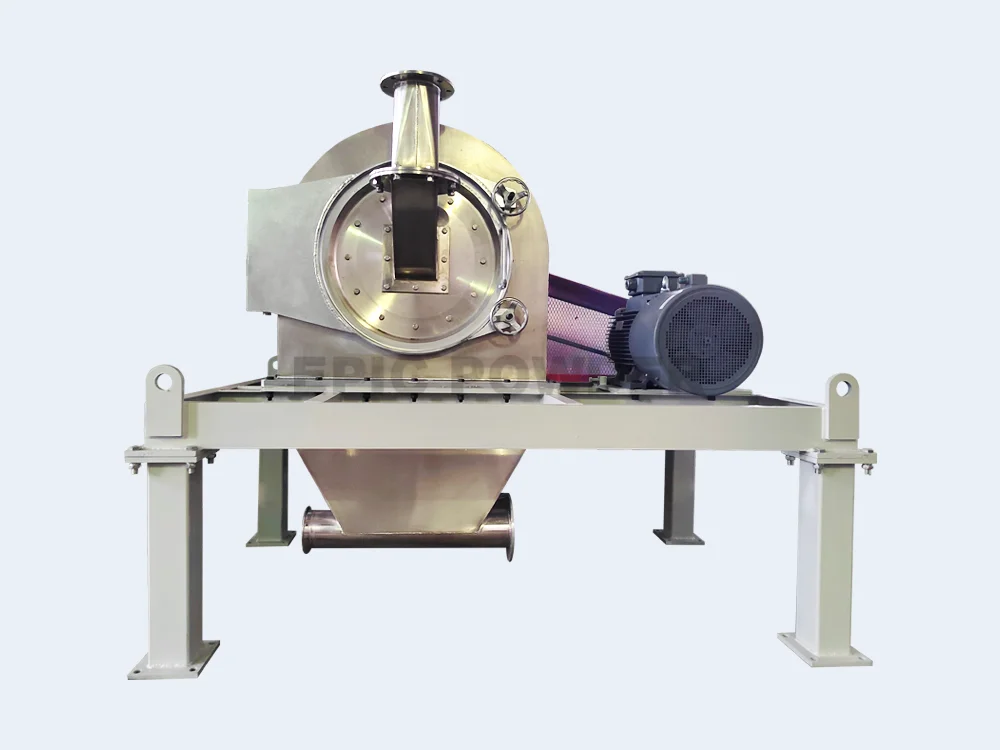

Spiral Jet Mill

Complete CIP and SIP systems capability. With spiral jet mill technology, the size reduction is achieved by collisions between particles of the substance, previously accelerated by high-speed jet streams. Target PSD is generally below 30μm when adopting this technology.

Working Principle

MQP disc jet mill, also known as spiral jet mill, the basic principle is: use the negative pressure generated by compressed air to suck the material in the hopper into the flat grinding chamber; The high-speed airflow (sonic speed or even supersonic speed) collides and crushes each other, and the materials that reach a certain particle size will approach the center of the grinding chamber due to the reduction of centripetal force, and will be discharged from the grinding chamber with the flow of airflow, and then enter the cyclone and dust collector.

Features And Benefits

- Without any rotating parts, CNC precision machining, no welding seam, easy to clean.

- No medium grinding, the grinding chamber can be protected by stainless steel and wear-resistant ceramics to ensure product purity.

- Low temperature grinding, especially suitable for grinding heat-sensitive, low-melting, sugar-containing and volatile materials.

- The grinding process is extremely short, the crushing efficiency is high, and the over-grinding is less.

- Suitable for grinding, dispersing and depolymerizing, and particle shaping of materials with various hardness.

- The whole system is closed, without dust, low noise and easy to operate.

Technical Parameters

| MODEL | Feeding Size(mm) | Particle size(D97:μm) | Production Capacity(kg/h) | Air consumption(m³/min) | Air pressure(Mpa) | Installed power (kw) |

|---|---|---|---|---|---|---|

| MQP01 | < 2 | 8~150 | -- | 1 | 0.7~0.85 | 7.5 |

Related Products

Project Cases

Related Posts

Send Us A Message

info@epic-powder.com

PHONE

+86 15762272120 Mon to Fri 08:00 am – 6:00 pm

LOCATION

NO. 369, Road S209, Huanxiu, Qingdao City, 266201, Shandong Province, CHINA