If you’re aiming for ultrafine grinding that delivers consistent, contamination-free powders below 5 microns, then a jet mill is your secret weapon. Whether you’re in pharmaceuticals, chemicals, or advanced materials, understanding jet mills is key. They use high-speed air streams to operate effectively. They break particles apart without causing wear. In this post, you’ll discover why jet mills for ultrafine grinding outperform traditional methods, how they boost efficiency, and why EPIC Powder Machinery’s cutting-edge designs are trusted worldwide for precision and scalability.Ready to elevate your powder processing? Let’s dive in.

What Is Ultrafine Grinding and Why Jet Mills

Ultrafine grinding is the process of reducing particles to extremely small sizes, typically below 10 microns, often reaching sub-micron levels. This level of fineness is essential in industries where material performance, reactivity, or texture depends heavily on particle size. Achieving a consistent ultrafine particle size distribution requires precise, efficient technology.

Jet mills are a top choice for ultrafine grinding. They use high-speed jets of compressed air or gas to speed up particles. These particles collide in the mill. They break down into ultrafine powders. This process doesn’t need mechanical parts, which wear out fast.This wear-free powder processing ensures clean, contamination-free results critical for high-purity ultrafine powders.

The science behind jet milling revolves around opposed jet grinding technology or variations like the spiral jet milling process. These methods use carefully controlled airflow patterns to create friction and impact between particles. As particle size decreases, the energy required to break them also changes, making jet mills highly energy-efficient for ultrafine particle size reduction.

Jet mills let you control particle size precisely. They use air classifiers to ensure consistent milling at target sizes from 0.5 to 10 microns. Jet mills are the top choice for ultrafine grinding. They offer efficiency, precision, and contamination-free grinding. This makes them ideal for hard and heat-sensitive materials.

If you want to learn more about automation and optimization in jet mill operations, check out EPIC Powder Machinery’s advanced solutions for ultrafine grinding.

Ready to explore how jet milling can elevate your material’s performance? Let’s dive into the key benefits and applications next.

Key Benefits of Jet Mills for Ultrafine Grinding

Jet mills offer several advantages when it comes to ultrafine grinding, especially for U.S. manufacturers looking for reliable and efficient powder processing solutions. Here’s why jet mills stand out:

- Consistent Ultrafine Particle Size DistributionJet mills use high-speed air jets to grind materials, allowing you to achieve a tight and consistent particle size, often down to 0.5 to 10 microns. This precision is crucial in industries like pharmaceuticals and chemicals.

- Wear-Free Powder ProcessingUnlike traditional mills that rely on metal parts to crush materials, jet mills use opposed jet grinding technology with no moving parts touching the product. This means less contamination, longer equipment life, and minimal maintenance.

- Suitable for Hard and Heat-Sensitive MaterialsThe cold grinding process in a fluidized bed jet mill prevents overheating, protecting sensitive materials such as pigments, food powders, and pharmaceuticals from degradation.

- Energy Efficiency and Cost SavingsJet mills consume less energy compared to other ultrafine grinding methods. Plus, their ability to integrate with air classifiers allows for precise control, reducing waste and improving overall efficiency.

- Scalable and Flexible for Various ApplicationsWhether you need to micronize pharmaceuticals, produce high-purity ultrafine powders for cosmetics, or grind mining minerals, jet mills handle diverse materials with ease.

- Minimal Cross-Contamination with Easy CleaningThe simple design of a jet mill makes cleaning quick and straightforward, an essential factor for U.S. facilities handling multiple product runs.

In short, jet mills deliver precise, energy-efficient, and low-maintenance ultrafine grinding—helping U.S.-based businesses meet their production demands without compromise.

Applications Across Industries Where Jet Mills Shine

Jet mills for ultrafine grinding are widely used across many industries in the U.S. because they deliver consistent, high-quality results with efficient ultrafine particle size distribution. Here’s where they really make a difference:

Chemicals and Pigments

Jet mills handle the toughest chemicals and pigments with ease. Using fluidized bed jet mill or spiral jet milling processes, manufacturers get uniform, wear-free powders that improve product performance, color brightness, and mixability. It’s ideal for producing high-purity ultrafine powders needed in coatings, plastics, and printing inks.

Pharmaceuticals and Food

In pharma, micronization for pharmaceuticals is critical for bioavailability and consistent dosing. Jet mill micronizers reduce particle sizes down to sub-micron levels without heat buildup, preserving ingredient integrity. The same tech works wonders in food processing—grinding spices, flour, and additives to fine, uniform textures that enhance flavor and dissolve better.

Mining Minerals and Battery Materials

Opposed jet grinding technology makes jet mills perfect for mining and minerals, delivering ultra-fine powders for downstream applications like ceramics and catalysts. Battery manufacturers also rely on jet mills to produce uniform, ultrafine particles essential for battery cathodes and anodes, improving energy efficiency and charging speeds.

Lithium iron phosphate jet mill ultrafine grinding case

Granuality:D50:1μm

Emerging Uses Nanomaterials and Cosmetics

Nanomaterials require extreme precision in size control—jet mills fit the bill here with their air classifier integration options, allowing fine tuning of ultrafine particle size distribution. Cosmetics brands use jet mill particle size reduction to create smooth powders and creams with better coverage, texture, and feel, meeting customer demands for premium products.

Jet mills are a versatile choice for anyone needing precise, efficient, and contamination-free ultrafine grinding. Whether it’s hard materials or delicate compounds, these mills deliver solid results across a wide range of U.S. industries.

Choosing the Right Jet Mill Factors and EPIC Solutions

Critical Selection Criteria

Picking the right jet mill for ultrafine grinding isn’t one-size-fits-all. You want to consider some key points before making a choice:

- Material hardness: Harder materials need robust jet mills designed for wear-free powder processing.

- Target particle size: Look for a mill that reliably delivers ultrafine particle size distribution, especially if you aim for sub-micron grinding applications.

- Production capacity: Match the mill’s throughput with your required volume without compromising energy efficiency.

- Purity requirements: High-purity ultrafine powders demand mills with minimal contamination risk.

- Air classifier integration: This helps in controlling particle size and improving classification accuracy.

- Energy consumption: Efficient ultrafine grinding saves on operating costs, so prioritize energy-efficient jet mill designs like the spiral jet milling process or opposed jet grinding technology.

EPIC Powder Machinery’s Ultrafine Jet Mill Lineup

EPIC Powder Machinery brings a solid range of jet mill micronizers perfect for various needs in the U.S. market:

- New-type Pneumatic Ultra Fine Grinding Mill: Delivers efficient ultrafine grinding of hard materials at particle sizes from 0.5 to 10 microns.

- Fluidized bed jet mill models: Known for wear-free powder processing and consistent ultrafine particle size distribution.

- Customizable options: EPIC can tailor jet mills to fit specific applications from pharmaceuticals to battery materials.

Installation and Optimization Tips

Getting your jet mill up and running smoothly requires more than just unboxing. Here are some practical tips:

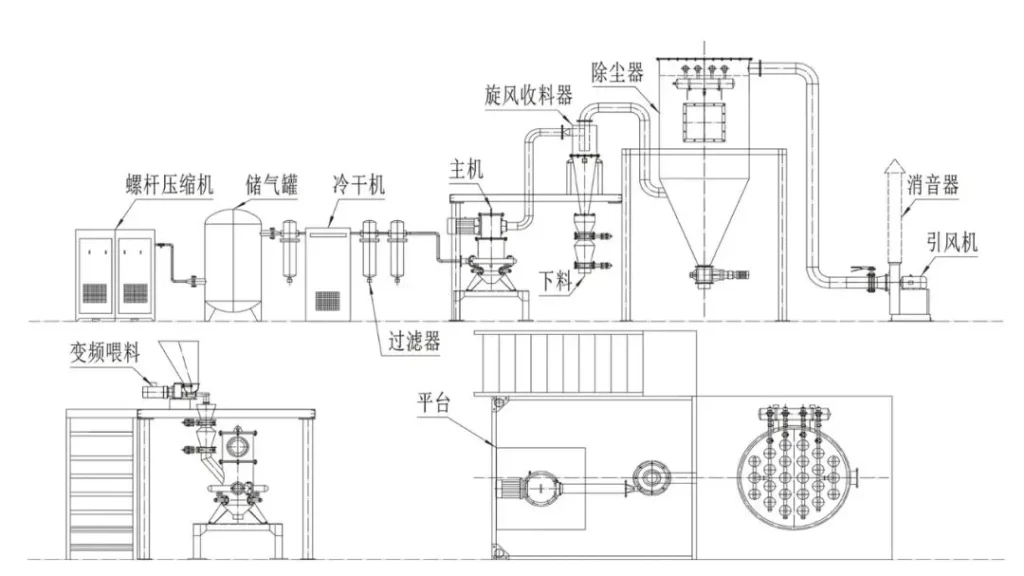

- Proper set-up: Ensure the mill is installed on a stable, vibration-free surface, with adequate airflow and dust collection systems.

- Optimize air pressure: Adjust compressed air levels to balance grinding efficiency and energy consumption.

- Routine maintenance: Regularly inspect wear parts to keep your mill operating at peak performance.

- Test runs: Perform trial grinding to dial in parameters for your specific material and desired ultrafine particle size distribution.

- Training: Make sure your operators understand the jet mill’s controls and safety procedures for smooth day-to-day operation.

By focusing on these factors and leveraging EPIC Powder Machinery’s solutions, you can maximize your jet mill’s performance and achieve consistent, high-quality ultrafine powders tailored for U.S. industry needs.

Real-World Case Studies EPIC Jet Mills in Action

At EPIC Powder Machinery, our jet mills are proven performers across many industries here in the U.S. Let’s look at a few success stories that highlight how our ultrafine jet mill solutions tackle tough grinding challenges.

Pharmaceutical Micronization

One major pharma manufacturer needed consistent ultrafine particle size for better drug absorption. Using our fluidized bed jet mill with air classifier integration, they achieved a tight particle size distribution in the 1-5 micron range. This improved both product quality and process efficiency, thanks to wear-free powder processing and energy-efficient operation.

Mining and Battery Materials

A battery materials company struggled with grinding hard minerals down to ultrafine sizes without contamination. Our opposed jet grinding technology provided a high-purity ultrafine powder consistently under 10 microns. This directly boosted battery performance while reducing downtime from equipment wear.

Cosmetics and Nanomaterials

A cosmetics brand wanted sub-micron grinding applications to improve product texture and stability. Utilizing our spiral jet milling process, we helped them achieve ultra-fine powders that enhanced their formulations and ensured smooth skin application.

Our New-type Pneumatic Ultra Fine Grinding Mill also proved valuable for manufacturers needing efficient ultrafine grinding of hard materials while maintaining high throughput and low energy use.

These real-world examples demonstrate how EPIC Powder Machinery’s jet mills provide reliable, scalable, and cost-effective solutions for ultrafine grinding. Whether the goal is micronization for pharmaceuticals, producing high-purity ultrafine powders, or wear-free powder processing, our jet mills are ready to deliver results tailored to the needs of U.S. industries.

Future Trends in Jet Mill Technology

The future of jet mill technology looks promising, especially as industries in the U.S. push for more efficient and precise ultrafine grinding solutions. Here are some trends shaping the next wave of jet mills:

- Energy Efficiency ImprovementsNew designs focus on reducing jet mill energy consumption without sacrificing grinding quality. This means more cost savings and a smaller environmental footprint.

- Advanced Air Classifier IntegrationBetter integration of air classifiers is helping achieve tighter ultrafine particle size distribution, even hitting sub-micron ranges more consistently.

- Wear-Free and Low Maintenance DesignsInnovations are minimizing wear on internal components, making mills last longer and reducing downtime — a big plus for continuous operations.

- Smart Automation and MonitoringIncorporating sensors and automation allows real-time monitoring of particle size and system health, helping operators optimize processes on the fly.

- Expanded Use in Nanomaterials and High-Purity PowdersAs demand grows for nanomaterials and ultra-pure powders, jet mills are evolving to handle delicate materials while preserving quality—important in pharmaceuticals and advanced battery materials.

- Customization and Modular SetupsFuture jet mills will offer more flexible setups tailored to specific industry needs, such as adapting spiral jet milling processes for various materials and hardness levels.

For U.S. businesses needing reliable jet mill micronizers or ultrafine grinding mills, staying ahead means investing in these next-gen features. EPIC Powder Machinery’s lineup is already embracing many of these trends to deliver efficient, precise, and scalable ultrafine grinding solutions.

If you would like to learn more about Jet Mill, please contact us