Fluidized Bed Air Jet Mill: Principle and Structure

The Fluidized Bed Air Jet Mill is top-notch in dry powder processing. It combines milling and classification in one compact unit. This system uses high-speed airflow instead of grinding media like traditional mills. It creates a dynamic fluidized bed in the chamber. The design ensures purity and efficiency. It usually has a vertical cylindrical chamber. Around the base, there are multiple supersonic nozzles. At the top, a high-precision turbine classifier is positioned. This design eliminates the need for moving grinding parts, significantly reducing wear and preventing metallic contamination.

Core Working Principle of Fluidized Bed Air Jet Mill

The Core Working Principle of Fluidized Bed Air Jet Mill relies on the energy of compressed air. High-pressure air is accelerated through specially designed Laval nozzles to supersonic speeds, injecting into the grinding chamber. This creates a fluidized state where raw material particles are accelerated and collide with each other at the intersection of the air streams.

- Self-Grinding Mechanism: Pulverization occurs solely through particle-to-particle impact and friction, ensuring the material does not grind against the machine walls.

- Adiabatic Expansion: As the compressed air expands at the nozzle exit, the temperature drops, creating a cold milling environment ideal for heat-sensitive and low-melting-point materials.

Key Components and Their Functions

To achieve precise ultra-fine grinding, the system relies on several critical components working in unison:

- Supersonic Nozzles: Convert pressure energy into kinetic energy, driving particles to collide.

- Turbine Classifying Wheel: A horizontal or vertical rotor that separates fine powder from coarse material based on centrifugal force.

- Screw Feeder: Automatically regulates the feed rate to maintain a stable powder-to-air ratio.

- PLC Control System: Orchestrates the entire operation, allowing for automated adjustment of parameters like wheel speed and system pressure.

Particle Size Control: Core Connotation and Evaluation Indicators

In high-tech industries such as pharmaceuticals, battery materials, and advanced ceramics, “grinding” is insufficient; precise Particle Size Control is the objective. This concept moves beyond simply reducing material size; it encompasses the ability to engineer the particle shape and strictly limit the distribution range.

Definition of Particle Size Control in Milling Process

Definition of Particle Size Control in Milling Process refers to the systematic manipulation of equipment parameters to achieve a specific geometric diameter and distribution curve. In a fluidized bed jet mill, this is primarily achieved by balancing the aerodynamic drag force (pulling particles out) against the centrifugal force (rejecting particles back to the grinding zone) generated by the classifying wheel.

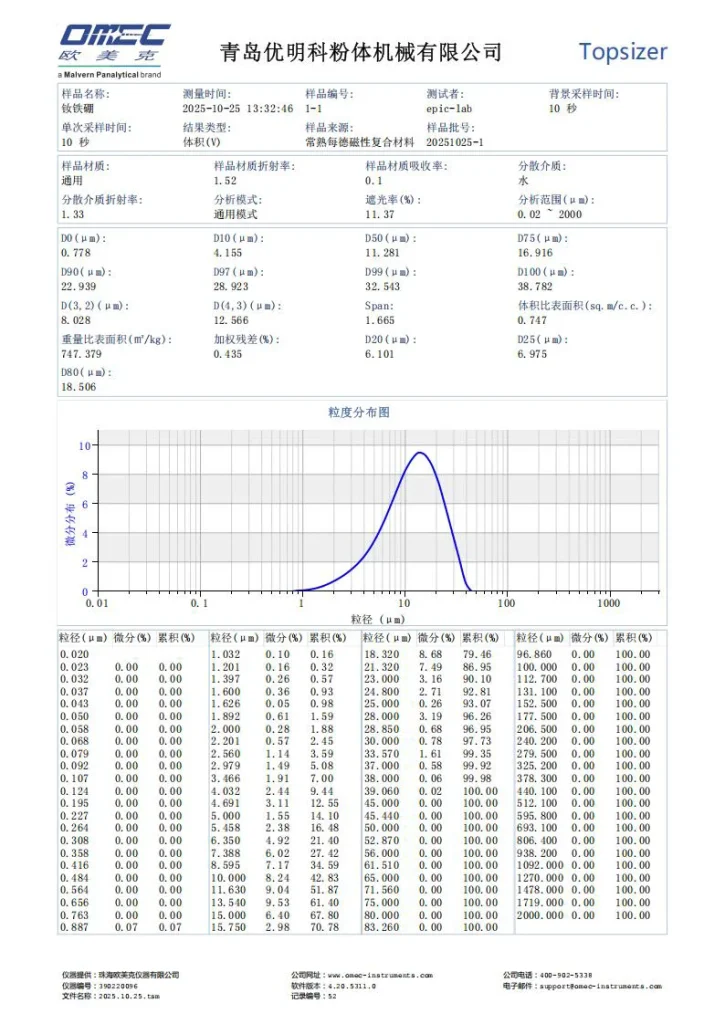

Critical Evaluation Indicators (D10, D50, D90, PSD Span)

To quantify success, we utilize specific metrics that define the quality of the powder:

- D50 (Median Diameter): The value where 50% of the particles are smaller and 50% are larger. This is the primary benchmark for average size.

- D90 & D10: Indicate the coarse end (D90) and fine end (D10) of the distribution. A lower D90 ensures no oversized particles exist.

- PSD Span: Calculated as $(D90 – D10) / D50$. A smaller span indicates a steeper, narrower distribution curve, which is a hallmark of high-quality jet milling.

Characteristics of Fluidized Bed Air Jet Mill in Particle Size Regulation

The fluidized bed system offers distinct advantages in regulation compared to other milling technologies:

- High Precision: Capable of achieving particle sizes between 0.5μm and 45μm with extreme accuracy.

- Adjustable Cut Point: The classifying wheel speed is controlled via variable frequency drive, allowing for instant adjustments to the product fineness without stopping the machine.

- Sharp Classification: The integrated classifier effectively prevents coarse particles from bypassing the grinding zone, ensuring a uniform output with a narrow particle size distribution.

How Do Fluidization and Jet Energy Cooperate to Regulate Particle Size?

Synergistic Mechanism of Fluidization State and Jet Impact

In our fluidized bed air jet mills, controlling particle size isn’t just one action. It’s a careful balance between airflow energy and fluidized bed mechanics. Compressed air is pushed through supersonic nozzles into the grinding chamber. This creates a fluidized state where the material particles are suspended in the air stream.

The control mechanism works through two primary forces:

- Impact Energy (Grinding Force): The high-speed airflow drives particles to collide with each other. By adjusting the pressure of the compressed air, we control the intensity of these collisions. Higher pressure generally results in finer particles due to higher impact energy.

- Centrifugal Force (Classification Force): Inside the chamber, a high-speed turbine classifying wheel spins to separate the product. The speed of this wheel determines the “cut point.” Lighter particles get carried away by the airflow and pass through the wheel. Coarser particles, however, are pushed back by centrifugal force. They go back for more grinding.

By balancing the nozzle pressure (grinding energy) and the classifier speed (separation threshold), we achieve precise How Do Fluidization and Jet Energy Cooperate to Regulate Particle Size? effectively. This makes sure that only particles that meet the D50 or D97 requirements leave the system. The others stay in the fluidized bed for more processing.

Why Does Particle Agglomeration Occur and How to Avoid It?

Causes of Agglomeration and Corresponding Control Measures

Particle agglomeration is a common challenge in ultra-fine grinding, where fine particles stick together, mimicking larger particles and reducing separation efficiency. This usually happens due to Van der Waals forces, static electricity, or moisture content in the raw material. In some cases, heat generated during processing can cause low-melting-point materials to soften and clump.

We address these issues through the inherent design of the fluidized bed air jet mill and specific operational controls:

- Cold Milling Environment: The adiabatic expansion of compressed air as it leaves the nozzles absorbs heat, significantly lowering the temperature inside the milling chamber. This is critical when processing heat-sensitive materials like PEEK or other polymers, preventing them from melting or sticking.

- Dry Air Supply: We ensure the compressed air used is free of moisture and oil. Introducing dry air prevents capillary forces that bind particles together.

- Dispersing Agents: For extremely fine powders prone to static, we can introduce specific additives or adjust the airflow dynamics to keep particles dispersed within the fluidized bed.

By maintaining a dry, cool, and highly turbulent environment, we prevent the conditions that favor agglomeration, ensuring the output remains a free-flowing, ultra-fine powder.

Benefits of Effective Particle Size Control

Optimize Product Performance and Application Adaptability

When we talk about how does a fluidized bed air jet mill control the particle size, we are really talking about unlocking the full potential of a material. In industries like pharmaceuticals and new energy, the specific surface area and particle distribution directly dictate chemical reactivity and dissolution rates. By achieving a narrow particle size distribution (PSD) without “overs” or “fines,” we ensure the powder behaves exactly as intended in its final application. This level of precision is critical for high-tech materials processing, where even minor deviations can compromise the performance of sensitive components like battery cathodes or advanced ceramics.

Improve Milling Efficiency and Reduce Energy Consumption

Precise control mechanisms prevent the common problem of “over-grinding.” In our fluidized bed systems, the integrated turbine classifier immediately separates qualified fine powder from the coarse material. This means energy is focused solely on grinding particles that actually need it, rather than wasting compressed air on dust that is already fine enough.

- Reduced Waste: Prevents energy loss on ultra-fine particles.

- Higher Throughput: Qualified material exits the system faster, freeing up space for new feed.

- Cost Savings: Optimized airflow and pressure settings lower the overall power consumption per ton of product.

Ensure Batch-to-Batch Product Consistency and Quality Stability

Reliability is the backbone of our manufacturing philosophy. Once the critical parameters—such as classifier speed, air pressure, and feed rate—are locked into the PLC system, the mill reproduces the exact same results run after run. This eliminates the variability often seen in mechanical milling. Whether you are running a test batch or continuous production, the characteristics of fluidized bed air jet mill in particle size regulation ensure that the D50 and D97 values remain stable. This consistency allows manufacturers to guarantee uniform quality to their downstream clients, building trust and reducing rejection rates.

Step-by-Step Particle Size Control Operation

Pre-Milling Preparation

Before we even power up the mill, the foundation for precise control is laid during preparation. Raw Material Pretreatment (Drying, Impurity Removal) is non-negotiable. Excess moisture causes particles to stick, disrupting the fluidization and clogging the supersonic nozzles. We ensure the material is dry and flowable. Additionally, we filter out large foreign debris that could damage the internal lining or the grading wheel.

Next, we move to Equipment Inspection and Inert Gas Purging. We check the integrity of the seals and the condition of the nozzles. For flammable or explosive materials, we purge the system with nitrogen to create an oxygen-free environment, ensuring the process remains safe and chemically stable.

Parameter Setting and Trial Milling

This phase is where we dial in the specific requirements for the product. The Initial Parameter Configuration (Air Pressure, Feed Rate, Classifier Speed) is set based on the material’s hardness and the target fineness (D50).

- Air Pressure: We set the pressure at the grinding nozzles to generate the necessary supersonic velocity for particle collision.

- Classifier Speed: This is the most critical variable. We set the RPM of the turbine wheel to define the “cut point.” Higher speeds block coarse particles, forcing them back for more grinding.

- Feed Rate: The screw feeder is adjusted to maintain a consistent material load within the chamber.

During Trial Milling and Parameter Optimization Based on PSD Test, we process a small batch. We immediately analyze the output using a laser particle size analyzer. If the powder is too coarse, we increase the classifier speed; if it’s too fine, we lower it or increase the feed rate.

Formal Milling and Real-Time Monitoring

Once the trial results hit the mark, we transition to full-scale production. The goal here is the Stable Operation of Fluidized Bed System. The material concentration inside the chamber must remain constant to ensure uniform particle collision.

We rely on Real-Time Tracking of Particle Size and Parameter Adjustment via the PLC control system. The system monitors the current load on the classifier motor. A fluctuation in current often indicates a change in the fluidized bed density. The system can automatically fine-tune the classifier speed or feed rate to compensate, ensuring consistent quality for high-tech applications like positive and negative lithium battery materials.

Post-Milling Treatment and Quality Inspection

After the grinding and classification are complete, the finished powder is collected in the cyclone separator or bag filter. We perform a final quality inspection to verify the particle size distribution (PSD) span. Regular inspection of critical accessories and service parts, such as the grading wheel and nozzles, is performed immediately after the run to detect wear that could affect the precision of the next batch.

Practical Application Results

Particle Size Control for Lithium Battery Cathode Materials

In the rapidly evolving battery sector, consistency is non-negotiable. When processing lithium battery cathode materials, we prioritize maintaining the structural integrity of the particles while achieving precise sizing. Our fluidized bed jet mills are specifically engineered to handle these high-hardness materials without introducing metallic contamination, thanks to optional ceramic linings.

By fine-tuning the classifier wheel speed, we can strictly control the particle size distribution (PSD). This ensures a steep curve where the D50 is optimized for high tap density, which directly correlates to better battery performance.

- Contamination-Free: Self-grinding mechanism prevents iron impurities.

- Precision Classification: Eliminates oversized particles that could damage battery separators.

- Uniformity: Achieves a narrow PSD for stable charge/discharge cycles.

Particle Size Regulation for Fine Chemical Powders

Fine chemicals often present unique challenges, such as heat sensitivity or low melting points. We leverage the cold operation principle of our equipment, where the adiabatic expansion of compressed air naturally lowers the temperature in the milling chamber. This allows us to grind heat-sensitive chemicals to sub-micron levels without degradation or melting.

For these applications, the integration of a high-precision air classifier is critical. It allows us to set a strict upper limit on particle size (D97), ensuring that the final powder meets the exact specifications required for downstream processing or formulation.

- Temperature Control: Prevents material melting or chemical changes.

- Adjustable Fineness: Easily shifts between D50 2μm and 45μm based on product needs.

- Closed-Loop System: Keeps the process dust-free and prevents loss of valuable raw materials.