Achieving the same particle size in lithium iron phosphate is hard. You need to watch every step in the grinding process. This helps batteries work well every time. Picking suitable ultrafine grinding equipment is important. It lets you make material that is always the same. Keeping particle size the same helps you maintain high quality. It also helps you follow safety rules for lithium iron phosphate uses.

Key Takeaways

- Keeping particle size the same helps batteries work better and last longer.

- Pick ultrafine grinding equipment that lets you control size and shape easily. This helps batteries work more efficiently.

- Take care of grinding equipment often and check it to keep results steady. This stops expensive problems from happening.

- Use tools that check particle size during production. You can change things quickly if needed.

- Use quality control steps like adding surfactants and keeping the right temperature. This makes particle size more even.

Importance of Particle Size Consistency

Battery Performance Impact

It is important to keep particle size the same. This helps lithium iron phosphate batteries work their best. Using suitable ultrafine grinding equipment lets you control particle shape and size. Round particles can make tap density higher and help batteries work faster. But, just making particles compact does not always make batteries better. If particle sizes are not the same, batteries may not work well. They can also become less dependable.

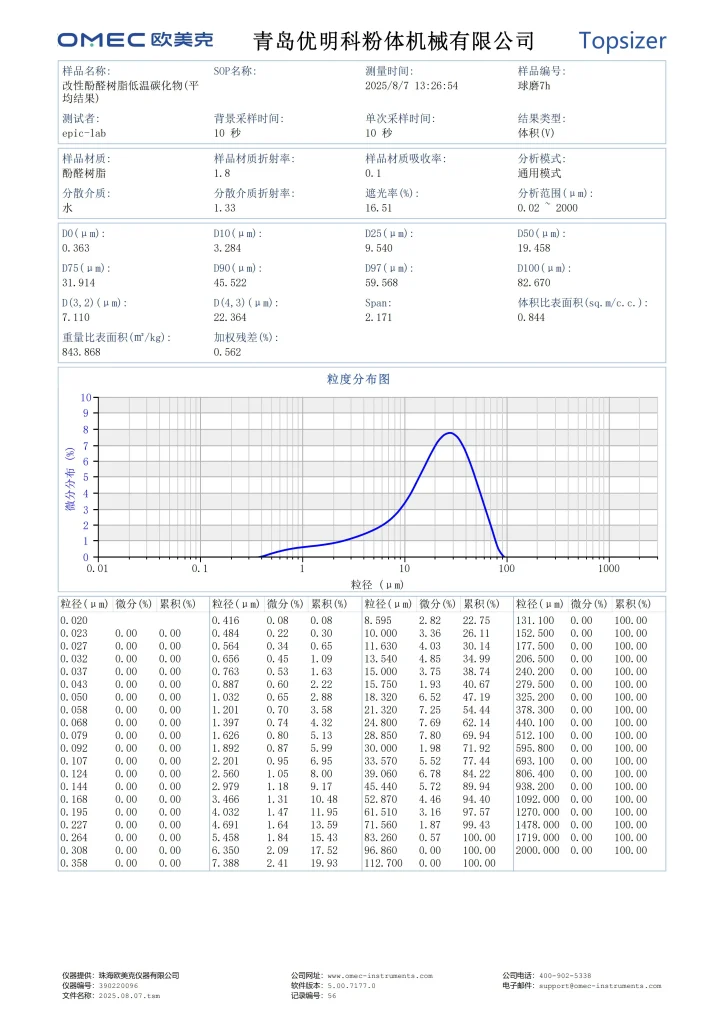

Manufacturers use laser diffraction and dynamic light scattering to measure particle size. These ways help you check if the grinding process makes the right size. How long you grind changes the particle size. This also affects tap density and how well batteries work.

Tip: Pick suitable ultrafine grinding equipment for balanced particle size. This helps batteries last longer and work better.

Here is a table that shows how particle size changes cycle life and energy density:

| Particle Size | Effect on Cycle Life | Effect on Energy Density |

|---|---|---|

| Smaller | Improved | Lower |

| Larger | Compromised | Increased |

Smaller particles help lithium ions move quickly. They also help electrons transfer better. Bigger particles can give more energy but may not last as long. You need to choose the right size for your needs.

Material Stability and Safety

Keeping particle size the same helps lithium iron phosphate stay safe and stable. Using suitable ultrafine grinding equipment stops problems like over-crushing and uneven sizes. This lowers the chance of material breaking down. It also helps you follow safety rules.

Manufacturers say good grinding equipment can make cathode density go up by 26%. Higher density means batteries are more stable and less likely to fail. You should always check particle size to keep your material safe.

You can look at particle size ranges like 0.28 to 38.41μm. This helps make sure your product is good quality. Checking often and using the right equipment helps you avoid safety problems and makes batteries last longer.

Selection Criteria for Suitable Ultrafine Grinding Equipment

Particle Size Control Features

You need equipment that lets you change particle size easily. This helps you get the right shape and spread for your lithium iron phosphate. Having control over size helps batteries store energy better and last longer. Using suitable ultrafine grinding equipment lets you adjust the process for what you need.

Note: Getting active materials ready and making good slurry helps batteries work well.

Here is a table with the most important features to check in your equipment:

| Feature | Description |

|---|---|

| Airflow pulverizer | Makes great particle shapes, like round or potato shapes |

| Particle size distribution | Gives a small range with high tap density |

| Yield | Gets 75%-95% with little over-crushing |

| Material lining | Uses strong materials for pure and clean grinding |

| Air classifier | Lets you change size between 0.5 μm-100 μm |

| Stability | Works for a long time without problems |

| Operation | Closed system, quiet, and stops dust from escaping |

| Material contact cavity | Ceramic lining keeps iron out |

| Heating | No heat during crushing, keeps things cool |

| Energy consumption | Uses 15%-25% less energy than other jet mills |

| Control | Smart controls show status as you work |

When you pick suitable ultrafine grinding equipment, you can control these features better. This means your batteries will be safer and work better.

Grading and Separation Systems

Grading and separation systems help keep particle sizes the same. These systems sort particles by size so you get a tight range. When particle size is even, batteries work better and are safer. Advanced grading systems, like air classifiers, let you change the size range quickly.

The right grading system can make your battery start with more power. Look at the table below to see how particle size ratio changes battery output:

| Particle Size Ratio | Initial Discharge Capacity (mAh g−1) |

|---|---|

| LFP-1 (small) | 154.82 |

| LFP-2 (medium) | 143.2 |

| LFP-3 (large) | 102.4 |

| 3:1 Ratio | 159.4 |

You should pick suitable ultrafine grinding equipment with good grading and separation. This helps you get the best mix of battery power and stability.

Over-Crushing Prevention

Over-crushing can hurt your lithium iron phosphate and make batteries worse. You need equipment that stops this from happening. Jet mills use fast air to crush particles gently. They also grind again to break up clumps but keep particles from getting too small. The built-in system lets you pick only the right-sized particles.

Tip: Using airflow, fluid-bed, vacuum, and ultrafine grinding together helps stop over-crushing and keeps things running well.

When you use suitable ultrafine grinding equipment with these features, you keep your material safe and make batteries better. You also save energy. For example, the SCM Ultrafine Mill can use up to 30% less energy than older mills. Grinding can use half of your plant’s energy, so saving energy helps your costs a lot.

Recommended Equipment Types

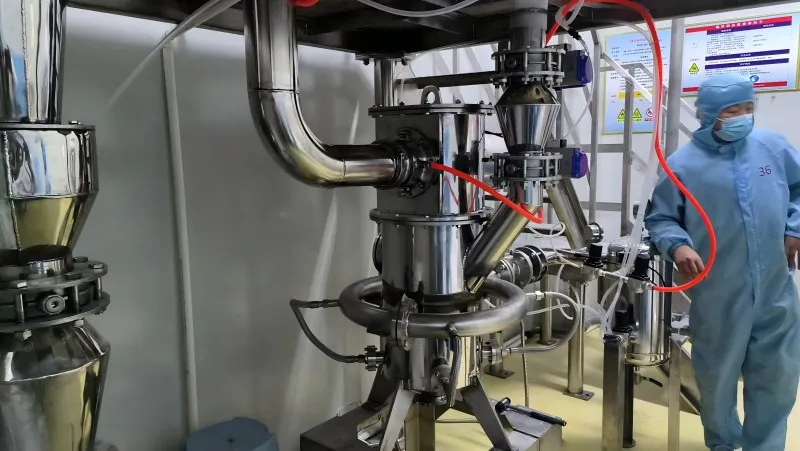

Picking the right equipment helps you get the best results. You need machines that give you control and work well. EPIC Powder Machinery has many choices that fit these needs.

Jet Mills for Lithium Iron Phosphate

Jet mills are good for making very fine powders. They can make particles between 1 and 10 microns. These mills do not get hot, so they are safe for heat-sensitive materials. Jet mills do not have moving parts that touch the powder. This keeps your product clean and safe from dirt.

| Grinding Technology | Advantages |

|---|---|

| Jet Milling | – Makes very fine powders (D50 ≤ 0.5 µm) – No dirt in the powder – No heat made – Small size – Can use special gas for sensitive materials |

Jet mills from EPIC Powder Machinery are a great pick if you need very pure and fine lithium iron phosphate.

Bead Mills and Vertical Mills

Bead mills are best for wet grinding jobs. They use small beads to break up particles fast and evenly. This gives you even particle sizes, which is good for batteries. Vertical bead mills grind well and keep particle sizes close together. Their special design helps you get the same results every time.

- Bead mills work fast and do a good job.

- Vertical bead mills run smoothly and make very fine particles.

- New wet grinding machines can work for 180 days without cleaning, which saves time and energy.

SCM Ultrafine Mill and Bar Pin Bead Mill

The SCM Ultrafine Mill lets you control particle size very well. It can make powder from 325 to 2500 mesh. It uses less energy than old mills and can make twice as much as jet mills. The bar pin bead mill also grinds finely and works without stopping. Both help you keep quality high and costs low.

- SCM Ultrafine Mill has a system that works well and keeps powder clean.

- Bar pin bead mills can run all the time and need less fixing.

When you pick good ultrafine grinding equipment like these, your process gets better and your battery materials improve.

Process Optimization for Consistent Results

Monitoring and Automation

You can keep particle size the same by using smart tools. Inline detection, like X-ray and infrared, checks size as you work. These systems warn you if something changes or goes wrong. You can fix problems fast. Big data helps you look at production numbers. It shows when machines need fixing and helps you plan better. Picking raw materials that are all the same size and very pure stops bad reactions. Making slurry and coating it well is important too. Smooth slurry and even coatings help batteries work right.

- Use inline detection to watch size all the time.

- Study data to know when to fix machines.

- Pick pure raw materials for better results.

- Make smooth slurry and coat evenly.

Tip: Automated tools help keep things steady and stop mistakes.

Maintenance and Calibration

Taking care of your equipment helps it work well. Cleaning stops dirt and buildup from messing up grinding. Lubrication makes moving parts last longer. Check seals and bearings often to find damage early. Calibration keeps the gap between rotor and stator just right. This is needed for the same particle size. Change old parts quickly so machines do not break.

- Clean machines and look for damage.

- Lubricate parts often.

- Check and set rotor-stator gaps.

- Change old parts when needed.

Note: Regular care makes equipment last longer and work better.

Quality Control Practices

Quality checks make sure lithium iron phosphate is always good. You can use surfactants like CTAB in the electrolyte. This makes particles smaller and more even. Keeping the temperature at 60 °C is important. It helps get the best size and stops clumping. Watching size at different temperatures shows 60 °C gives 1.3 μm average size. Higher heat makes sizes uneven.

| Quality Control Practice | Description |

|---|---|

| Use of Surfactants | Adding CTAB to the electrolyte makes particles smaller and more even, down to about 250 nm. |

| Temperature Control | Keeping the electrolyte at 60 °C gives the best size and shape, and stops clumping. |

| Particle Size Monitoring | At 60 °C, average size is 1.3 μm. At 70 °C, sizes are uneven and battery performance drops. |

You can get good results by using these steps and the right ultrafine grinding equipment.

You can keep particle size the same in lithium iron phosphate by using certain steps. First, use ultrasonication before mixing to help spread things out. Next, check the particle size closely to make sure it is right. Break up clumps with a two-step mixing process. Make both liquid and solid methods better to get good results. Pick suitable ultrafine grinding equipment and watch the process carefully. EPIC Powder Machinery has good machines for this job.

- Use ultrasonication at 510W to keep particle size steady.

- Check particle size to help batteries work better.

- Use two-step mixing to spread particles well.

- Make liquid and solid methods better for more power.

Picking the right equipment and steps helps you make high-quality lithium iron phosphate every time.

FAQ

What is the best way to measure particle size during grinding?

You can use laser diffraction or dynamic light scattering. These ways are quick and give correct results. They help you see if your grinding makes the right particle size.

How often should you calibrate ultrafine grinding equipment?

You should check and set your equipment every month. Doing this often keeps your particle size the same. It also helps you stop expensive problems.

Can you prevent over-crushing with automation?

Yes. Automation lets you watch grinding as it happens. You can set alerts if the size changes. This helps you stop over-crushing before it hurts your material.

Which equipment works best for lithium iron phosphate?

Jet mills and bead mills are good for lithium iron phosphate. These machines make fine and clean powder. EPIC Powder Machinery has good choices for your needs.

“Thanks for reading. I hope my article helps. Please leave a comment down below. You may also contact EPIC Powder online customer representative for any further inquiries.“

— Jason Wang, Engineer Learn more