What Is a Jet Pulverizer Machine?

If you need consistent ultra-fine powder without contamination or heat damage, you’re looking for a jet pulverizer machine (also called a fluid jet mill, air jet pulverizer, or micronizer machine).

In simple terms, a jet pulverizer machine uses high‑pressure compressed air or gas to accelerate particles so they collide with each other at very high speed. There are no mechanical grinding tools touching the product. The result is clean, repeatable micronization—precise particle size reduction down into the 1–45 μm range and, with the right setup, even sub-micron.

How Jet Pulverizer Technology Works (Plain Language)

At a high level, a jet pulverizer machine:

- Uses compressed air or inert gas instead of mechanical impact

- Accelerates particles through special nozzles into a grinding chamber

- Lets the particles collide with each other, breaking down to fine or ultra-fine sizes

- Uses an internal classifier to separate coarse from fine particles

- Continuously discharges only on-spec material, recirculating oversized particles

This “particle-on-particle” grinding inside a fluidized bed jet mill or opposed jet mill gives you:

- Very narrow particle size distribution

- Low contamination risk (no metal-on-product contact)

- Cooler grinding for heat-sensitive or friable materials

- Easy scale-up from laboratory jet mill to industrial jet mill

Why Our Jet Pulverizer Machines Stand Out

I design and supply jet energy mills and classifier mill systems specifically for high-demand global markets—pharma, chemicals, food, new materials, and more. Our focus is simple: efficiency, purity, and consistency, backed by real engineering, not marketing slogans.

Design Advantages: Efficiency, Purity, Consistency

We optimize every core element of the jet pulverizer machine:

- Optimized nozzle layout

- CFD-based nozzle positioning for stable fluidized bed

- Improved energy transfer from compressed air to particles

- Lower specific air consumption per kg of product

- High-precision integrated classifier

- Adjustable cut size for flexible PSD control

- Consistent d50 and d90 from batch to batch

- Reduced need for post-sieving or secondary classification

- Contamination control design

- No internal moving grinding parts in the micronization zone

- Wear-resistant, low-contamination liners (ceramic, PU, special steels)

- Suitable for pharmaceutical micronization and high-purity chemicals

- Thermal control and gas options

- Efficient use of compressed air for limited temperature rise

- Optional inert gas pulverizer mode (nitrogen, argon) for explosive or oxidizable products

- Ready for cryogenic jet grinding with integrated cooling

- Integrated dust-free powder processing

- Closed-loop compressed air milling system

- Dust-free feeding and collection

- Available clean-in-place jet mill (CIP) design for regulated industries

Jet Pulverizer vs Mechanical Mill: Quick Comparison

Below is a concise comparison between a jet pulverizer machine and a traditional mechanical mill (pin mill, hammer mill, ball mill). This reflects what most buyers actually care about: particle size, purity, heat, and total cost.

| Item / Feature | Jet Pulverizer Machine | Traditional Mechanical Mill |

|---|---|---|

| Grinding principle | Particle-on-particle via compressed air or gas | Mechanical impact (pins, hammers, balls) |

| Typical particle size range | 1–45 μm, sub-micron possible | ~50–200 μm, sometimes down to ~20–30 μm |

| Particle size distribution (PSD) | Very narrow, tight control with classifier | Broader PSD, more fines and coarse tails |

| Contamination risk | Very low, no grinding media contact | Higher; wear from tools and liners |

| Heat generation | Low, suitable for heat-sensitive materials | Higher; may require extra cooling |

| Best for | Pharma, high-purity chems, electronics, catalysts | Bulk minerals, coarse powders, non-critical products |

| Maintenance | No grinding media; focus on nozzles & filters | Regular replacement of mechanical parts |

| Energy usage per kg (typical) | Higher kWh/kg, but offset by quality & yield | Lower kWh/kg, but lower control & more rejects |

| Upfront cost | Higher | Lower |

| Total cost of ownership (TCO) | Often lower for high-value products | Lower for low-value, coarse products |

When a jet pulverizer machine is the right choice:

- You must hit strict PSD specs (e.g., d90 < 10 μm) every time

- You process high-value powders (pharmaceutical APIs, specialty chemicals, pigments, electronic materials)

- You need FDA-compliant milling equipment with traceable purity

- You want to minimize metal contamination, heat, or oxygen exposure

Why Choose EPIC for Jet Pulverizer Machines?

We position our EPIC jet pulverizer machines as a complete, engineered solution, not just a piece of hardware. That matters when you need reliable particle size reduction equipment that works the same day after day.

Key Reasons Customers Select Our Systems

- Application-driven design

Every system is sized and configured to your real product and process: target PSD, bulk density, flowability, explosivity, and hygiene requirements. - Global-ready engineering

We design for international markets with options for:- ATEX / IECEx explosion-proof design

- GMP and FDA-compliant pharma layouts

- Local electrical and safety standards

- Lab-to-plant scalability

We offer laboratory jet mills, pilot units, and full-scale industrial jet mills using similar geometry. That makes process transfer and scale-up predictable. - Process support and toll powder processing

Before you invest, we can run toll powder processing and trial batches to prove:- Feasibility of jet pulverizer particle size reduction

- Expected capacity and air consumption

- Final PSD and throughput in real operating conditions

- Reliable uptime and support

Robust design, standard components, and planned maintenance routines keep your system available. We back this with remote assistance, training, and spare parts programs.

A jet pulverizer machine is the go-to solution when you need:

- Ultra fine powder mill performance in the 1–45 μm range

- High purity, low contamination, and narrow PSD

- Safe handling of heat-sensitive, friable, or explosive powders

- Clean, dust-free, and often CIP-capable operation

Our EPIC fluid jet pulverizers combine proven jet milling principles with optimized design for efficiency, purity, and consistency. For high-value products, the gains in yield, quality, and compliance often far outweigh the higher initial investment compared to traditional mechanical mills.

Jet Pulverizer Machine Features and Specifications

I design every jet pulverizer machine to be compact, efficient, and easy to control. Below is what you actually get in terms of components, performance, and options.

Core Components of a Jet Pulverizer Machine

A complete industrial jet mill system normally includes:

- Air / Gas Supply – Clean, dry compressed air or inert gas, with pressure and flow precisely controlled.

- Feeder System – Screw or vibratory feeder for steady, low-pulse feeding of powders, from lab scale to full production.

- Grinding Chamber – Fluid jet mill / opposed jet mill design; particles collide in a high‑velocity jet stream instead of hitting mechanical parts.

- Classifier – Dynamic classifier wheel or integrated classifier mill system to cut and control top‑size, similar to our high-efficiency air classifying mill technology.

- Collection System – Cyclone + filter or dust-free powder processing bin, designed for clean, easy product recovery.

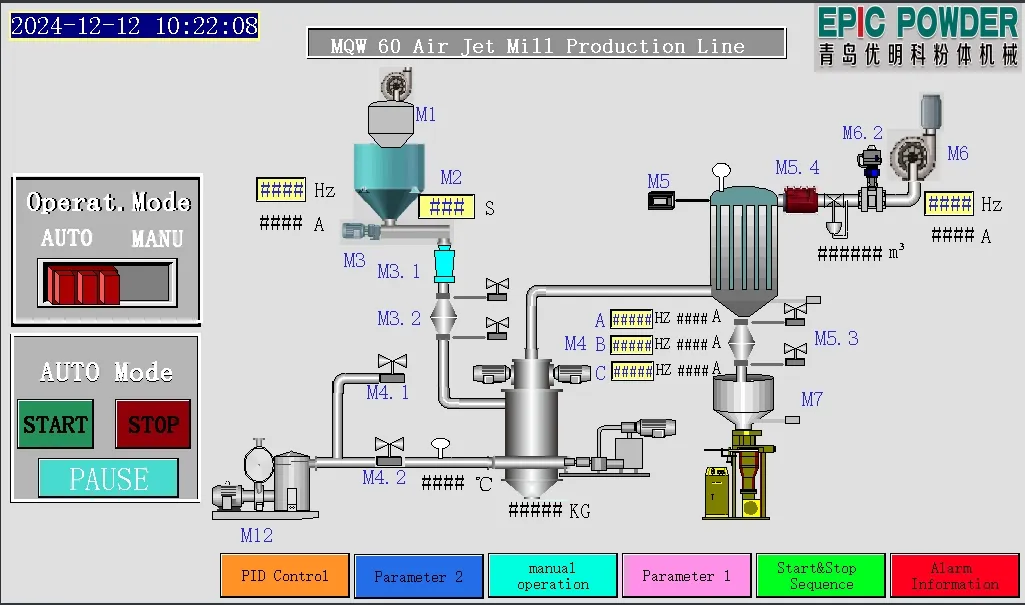

- Control Panel – PLC or DCS-ready controls for pressure, feed rate, product fineness, and interlocks.

Jet Pulverizer Machine Performance Specs

Typical ranges (customizable by model and configuration):

| Item | Typical Range / Option |

|---|---|

| Particle size (D97) | 1–45 μm (sub-micron particle reducer designs available) |

| Capacity | Lab: 0.1–10 kg/h; Industrial jet mill: up to several t/h |

| Feed hardness | Mohs up to 9 (friable material mill is most efficient) |

| Feed moisture | Usually <1–2% (higher with special configurations) |

| Materials handled | Pharmaceutical actives, fine chemicals, pigments, food, battery and advanced materials |

| Operating pressure | Commonly 0.6–1.2 MPa, higher for ultra fine powder mill |

We’ve run real projects such as zinc borate ultrafine grinding by air jet mill (D97: 4–8 μm, 126 kg/h), proven in this zinc borate ultrafine grinding case, so these specs are grounded in practice, not theory.

Construction, Sanitary Design, Compliance

I build the jet pulverizer machine to match your industry and regulatory needs:

- Contact materials – Stainless steel 304/316L; special alloys for high-purity or corrosive products.

- Surface finish – Polished internals for pharmaceutical jet mill and food-grade applications; Ra options available.

- Sanitary design – Crevice-free, smooth transitions, CIP-ready or clean-in-place jet mill layouts.

- Compliance – FDA-compliant milling equipment concepts, GMP-oriented design, CE marking, ATEX / NFPA options where required.

- Sealing & containment – High-level sealing, negative-pressure design, and dust-tight connections for safe, clean operation.

Customization Options and Configurations

Every application is different, so I customize the jet energy mill / micronizer machine around your product:

- Inline Classifiers – Fine-tuned classifier wheels for sharper jet pulverizer particle size reduction and flexible cut points.

- Cryogenic Jet Grinding – Liquid nitrogen or CO₂ cooling for heat-sensitive materials and better flow of sticky powders.

- Explosion-Proof Design – Inert gas pulverizer setups, explosion vents, and compliant control systems for solvent-bearing or explosive powders.

- Scale and Layout – Laboratory jet mill skids for R&D, pilot systems for scale-up, and full production lines.

- Integration – Easy tie-in with upstream dryers, downstream mixers, or toll powder processing lines.

This combination of smart core components, proven performance, hygienic construction, and targeted customization is what makes our jet pulverizer machine a reliable, long-term piece of particle size reduction equipment for global users.

Jet Pulverizer Machine Applications

Our jet pulverizer machines are built for global manufacturers who need tight particle size control, ultra-clean processing, and stable batch-to-batch performance. Below are the core application fields where our jet pulverizer machine / fluid jet mill / air jet pulverizer solutions deliver the most value.

Pharmaceutical & Nutraceutical Micronization

For pharma and nutraceuticals, particle size is product performance. I use our pharmaceutical jet mill and micronizer machine designs where purity and repeatability are non‑negotiable.

Typical applications:

- APIs (active pharmaceutical ingredients) – improve dissolution, bioavailability, and uniformity

- Inhalation drugs – narrow particle size distributions in the 1–5 μm range

- Nutraceuticals and herbal extracts – clean grinding without heat damage or metal contamination

- Controlled-release systems – tight cut size using integrated classifier mill systems

Key advantages for pharma/nutra:

- No grinding media, minimizing contamination risk vs mechanical mills

- Compatible with cGMP, FDA-compliant milling equipment, and validation requirements

- Options for inert gas pulverizer setups to handle oxygen‑sensitive or explosive APIs

- Available as laboratory jet mills for R&D and easy scale-up to production

Chemicals, Pigments & Catalysts

For chemical, pigment, and catalyst producers, consistency and color strength matter as much as throughput. Our industrial jet mill setups are designed for precise jet pulverizer particle size reduction of:

- Organic and inorganic pigments and dyes

- Battery and energy materials, similar to our lithium battery material processing lines shown in this lithium battery materials case study

- Catalysts and catalyst supports (e.g., alumina, silica, zeolites)

- Specialty chemicals, additives, and flame retardants

Why chemical customers choose a fluidized bed jet mill or opposed jet mill:

- High whiteness and color consistency for pigments

- Better surface area control for catalysts and performance additives

- Easy to configure for friable material mill duty or harder, abrasive materials

- Dust-tight, explosion‑relief and ATEX‑ready designs for hazardous powders

Food, Spices & Cosmetics

For food, spice, and cosmetic powders, the focus is clean processing, taste/color retention, and consistent texture. Our superfine powder grinder and ultra fine powder mill jet systems help you hit those targets.

Typical products:

- Spices, herbs, and seasonings – fine, uniform powder without burning or aroma loss

- Food additives – starches, sweeteners, functional fibers, and proteins

- Cosmetic powders – foundations, pigments, mica, and fillers for smooth skin feel

Benefits for these industries:

- Low-temperature grinding; cryogenic jet grinding available to protect aroma and color

- Dust-free powder processing for cleaner, safer plants

- Sanitary designs with clean-in-place jet mill options for frequent product changeovers

- Smooth, controlled particle size distribution for premium mouthfeel and cosmetic coverage

For coarser food applications, we also design full systems similar to our rice husk grinding and pulverizing lines in Malaysia and Thailand that show how we scale from lab to full industrial food milling (300‑mesh rice husk grinding line in Malaysia).

Advanced Materials & Electronics

In advanced materials, small particle size often means big performance gains. Our jet energy mill and sub-micron particle reducer systems are used across:

- Battery materials – cathode, anode, and conductive additives

- Ceramics and technical powders – zirconia, alumina, silicon carbide, boron nitride

- Electronic and magnetic materials – ferrites, metal powders, phosphors

- 3D printing powders – controlled particle size to improve flow and layer quality

What makes our classifier mill systems stand out:

- Stable sub‑10 μm and even sub-micron particle size capability

- Strong classification for narrow PSDs, improving electrical, mechanical, or optical properties

- Flexible compressed air milling systems with nitrogen or inert gas for reactive metals

Real‑World Jet Pulverizer Machine Case Highlights

Across markets, global customers use our micron master pulverizer and fluid jet pulverizer systems to improve both product quality and economics. Common results we see after installation:

- 30–50% tighter particle size distributions, boosting product performance

- Reduced contamination vs mechanical mills thanks to no media and minimal wear parts

- Higher uptime, with robust designs and easy access for maintenance

- Fast changeover between products, critical for toll powder processing and multi‑product plants

Whether you run a toll powder processing facility or an in‑house production plant, our jet pulverizer machine lineup is built to give you repeatable quality, lower risk, and a clearer path to scale-up—from laboratory jet mill trials all the way to full industrial systems.

How a Jet Pulverizer Machine Works

Step-by-step process: from feeding to collection

Here’s how our jet pulverizer machine (also called a fluid jet mill or air jet pulverizer) runs in a typical line:

- Feeding

- Material is fed from a hopper by a screw feeder or vibratory feeder.

- Feed rate is controlled to keep the grinding chamber stable and avoid overloading.

- For pharma and food, we use closed, dust-free feeding to protect both product and operators.

- Grinding in the jet zone

- The powder enters the grinding chamber where high-pressure air or gas drives the whole process.

- Multiple nozzles inject compressed air at high speed, creating a powerful jet stream.

- Particles collide with each other at high velocity (particle-on-particle impact), turning coarse powder into ultra-fine particles without metal contact.

- Classification

- A built-in classifier wheel (or static classifier, depending on design) spins at controlled speed.

- Fine particles that meet the target size are carried out with the airflow.

- Coarse particles are rejected and stay in the chamber for further grinding.

- This classifier mill system lets us reach tight particle size distributions without screens.

- Separation and collection

- The air/product mix moves to a cyclone and/or bag filter.

- Product is separated from the air stream and collected in bins, drums, or IBCs.

- Final air passes through a filter before being vented or recirculated, giving a clean, low-dust system.

For customers in chemicals and specialty powders, this process is very similar to our contamination-free air jet mill dry grinding setups, just customized to your product and local safety rules.

Role of compressed air or gas and nozzles

The heart of any industrial jet mill or micronizer machine is the compressed air system:

- Compressed air or gas

- Typically 6–10 bar compressed air for standard applications.

- Nitrogen or inert gas for explosive, oxygen-sensitive, or high-value materials.

- Stable pressure and flow mean stable particle size and throughput.

- Nozzle design

- Tangential or opposed jet nozzles are placed to create a fluidized bed inside the chamber.

- The nozzle angle and spacing control:

- Impact energy

- Residence time

- Fineness and efficiency

- For ultra fine powder mill performance, we use optimized nozzle geometries to hit sub-micron or tight d50 targets.

This pure jet energy milling approach avoids mechanical contact, which is why many customers call it a micron master pulverizer style system.

Classification, separation, and product recovery

Good classification is what separates a basic air jet pulverizer from a top-tier fluidized bed jet mill:

- Dynamic classification

- Classifier speed sets your cut size: faster speed = finer powder.

- Allows real-time tuning of particle size without changing hardware.

- Produces narrow distributions, ideal for pharmaceutical micronization and high-end chemicals.

- Separation

- Cyclone takes out most of the product by centrifugal force.

- Secondary filtration (bag filter / cartridge filter) captures ultra-fines and protects the environment.

- For dust-free powder processing, we integrate sealed discharge valves and contained transfer.

- Product recovery

- High-yield system design minimizes loss in ducts, filters, and corners.

- Smooth internal surfaces and smart geometry reduce product hold-up.

- For high-value APIs or specialty materials, this directly improves ROI.

Energy efficiency and maintenance considerations

With any compressed air milling system, energy and maintenance decide your long-term costs. We design our jet pulverizer machines to handle both:

- Energy efficiency

- Optimized nozzle and chamber design to get more grinding per m³ of air.

- Correct air-to-feed ratio to avoid wasting energy on over-fluidizing.

- Options like:

- Heat recovery from compressed air

- Variable-speed drives on classifiers and feeders

- Inert gas recirculation for high-consumption setups

- Maintenance

- No mechanical grinding media: fewer wear parts compared to mechanical mills.

- Key maintenance points:

- Nozzles and wear liners

- Classifier wheel and bearings

- Filters and seals

- Easy access doors and simple layouts reduce downtime.

- For pharma and food, we can design clean-in-place jet mill options to cut manual cleaning time and improve changeover speed.

In short, a modern jet energy mill gives you precise particle size reduction with low contamination, predictable performance, and controlled running costs—whether you’re using it as a production unit, a laboratory jet mill for development, or part of a full toll powder processing setup.

Jet Pulverizer Machine Benefits and ROI

A modern jet pulverizer machine is one of the fastest ways I know to turn tough raw materials into clean, consistent ultra-fine powder with strong ROI. Compared with traditional mechanical mills, a fluid jet mill or air jet pulverizer gives you higher throughput, fewer stoppages, and far better control over product quality.

Higher Throughput And Uptime

With no internal grinding media and almost no moving parts in the grinding zone, our industrial jet mill systems run stable and clean:

- Continuous, dust-free powder processing with fewer unplanned stops

- Fast recipe changeovers using automated controls and easy clean access

- Consistent micronization from lab-scale to full production for pharmaceutical micronization and high-value chemicals

Typical operational gains with a jet pulverizer machine:

| Benefit | Impact on your line |

|---|---|

| Stable particle size | Fewer off-spec batches, less rework |

| Minimal wear parts | Less downtime for maintenance |

| Closed, pressurized system | Better containment and operator safety |

| Cleaner grinding chamber | Faster cleaning between product runs |

Cost Savings And Total Cost Of Ownership

Our micronizer machines and fluidized bed jet mills are built to run for years under harsh conditions:

- Low mechanical wear thanks to jet energy milling instead of impact tools

- Longer service intervals and simple spare parts strategy

- Lower risk of batch loss in high-value pharma and specialty chemicals

ROI drivers you actually feel:

| Cost Factor | Jet Pulverizer Machine Advantage |

|---|---|

| Maintenance & spare parts | Lower long-term spend vs. pin or hammer mills |

| Product yield | Tight classification reduces fines and oversize |

| Labor & cleaning time | Sanitary, smooth surfaces cut manual cleaning time |

| Scale-up investment | Same technology from laboratory jet mill to plant |

For many global customers, payback often comes from just a few high-value product campaigns.

Quality, Purity, And Contamination Control

If you run pharmaceuticals, nutraceuticals, food, or battery materials, purity is non‑negotiable. A jet energy mill gives you:

- Very low metal contamination (no direct contact grinding tools)

- Smooth, easy-to-clean product-contact surfaces with FDA-compliant options

- Strong batch-to-batch consistency using integrated classifier mill systems

Our designs support dust-free powder processing and clean-in-place jet mill configurations for regulated environments.

Sustainability And Energy Use

Energy is one of your biggest operating costs. Our opposed jet mills and inert gas pulverizers are engineered to reduce waste:

- Optimized compressed air milling system with efficient nozzles and classification

- Lower product loss and scrap compared to friable material mills that over-grind

- Options for cryogenic jet grinding to protect heat-sensitive products without long cooling stages

If you’re planning a new line or upgrading old mechanical mills, our industrial jet mills and ultra fine powder mills give you a clear path to better uptime, cleaner product, and stronger long-term ROI.

EPIC Jet Pulverizer Machine Solutions

EPIC Powder Machinery expertise

At EPIC Powder Machinery, I focus on one thing: reliable, scalable jet pulverizer machines that actually run the way your plant needs them to. We’ve spent years building and optimizing industrial jet mills, fluidized bed jet mills, and laboratory jet mills for ultra-fine particle size reduction across pharma, chemicals, food, and advanced materials.

What sets our jet pulverizer machines apart:

- Deep process know-how in pharmaceutical micronization, pigments, metal powders, and high-purity materials

- Proven designs for sub-micron particle reduction with tight and repeatable particle size distribution

- Experience with inert gas pulverizers for oxygen-sensitive, flammable, or explosive powders

- Options for dust-free powder processing, clean-in-place jet mills, and FDA-compliant milling equipment for regulated industries

We don’t just ship a micronizer machine. We build a complete classifier mill system that fits your product, your utilities, and your quality standards.

Jet pulverizer testing, trials & toll powder processing

Before you commit to a full line, you probably want proof. That’s why I’ve built a flexible test and toll powder processing platform where you can see real results on your own materials.

What you can do with our testing and trial services:

- Run lab-scale jet milling trials to find the right air jet pulverizer setup, pressure, and classifier speed

- Validate target particle size range (D50 / D90) and flowability before full investment

- Test cryogenic jet grinding for heat-sensitive or soft materials that smear at room temperature

- Explore powder surface performance together with our powder coating and surface modification solutions for better dispersion and downstream behavior, as shown in our work on advanced powders such as silicon carbide powder modification

If you’re not ready to bring the equipment in-house, or you only have seasonal demand, we can also run your product as a toll processing partner using our jet energy mills and superfine powder grinders.

Customer success with EPIC jet pulverizer machines

Global customers use our jet pulverizer machines when conventional mills hit their limits on purity, fineness, or temperature. Typical wins we see on real installations:

- Pharmaceutical jet mill lines achieving consistent GMP-level micronization with low metal contamination and easy validation

- Pigment and catalyst plants that switch from mechanical mills to fluid jet mills and cut oversize particles and rework dramatically

- Food and spice producers improving flavor release and color strength thanks to uniform fine powder from our ultra fine powder mills

- Powder metallurgy and advanced materials customers, as in our powder metallurgy application cases, using opposed jet mills to reach fine, clean, and flowable metal and ceramic powders

Across these projects, the pattern is similar:

- More stable jet pulverizer particle size reduction

- Higher throughput per square meter of floor space

- Lower contamination, better cleanliness, and easier validation and audits

If you’re scaling from a laboratory jet mill to a full industrial jet mill, or looking for a micron master pulverizer setup that can actually keep up with production, that’s exactly the kind of problem EPIC Powder Machinery is built to solve.

Jet Pulverizer Machine FAQ

What Is the Minimum Batch Size and How Can I Scale Up?

For our industrial jet pulverizer machines, we support both tiny test runs and full-scale production.

- Minimum batch size: starts from around a few hundred grams on a laboratory jet mill, depending on material bulk density.

- Pilot to production scale-up: we keep the same classifier mill system design across lab, pilot, and industrial jet mill sizes, so PSD, flow behavior, and quality are consistent when you scale up.

- Typical scale path: lab micronizer machine → pilot fluid jet mill → full-size air jet pulverizer or fluidized bed jet mill.

- We also offer toll powder processing so you can validate your particle size reduction equipment performance before buying a full line.

How Do You Handle Heat-Sensitive or Explosive Materials?

We design the jet pulverizer machine around your material’s risk profile.

- For heat-sensitive powders, we use:

- Low product residence time in the grinding zone

- Compressed air milling system with optimized nozzle arrangement

- Optional cryogenic jet grinding with liquid nitrogen

- For explosive or solvent-laden materials, we can provide:

- Inert gas pulverizer systems with nitrogen or argon

- Explosion-proof motors, ATEX-compliant panels, and monitored earthing

- Oxygen monitoring and interlocks for safe startup and shutdown

- For friable material mill applications, we tune pressure and classifier speed to avoid over-grinding and thermal stress.

What About Installation, Lead Times, and Customization?

I design every jet pulverizer machine package to drop into your existing plant with minimal hassle.

- Installation support: layout review, utility list, foundation and anchor drawings, and on-site or remote commissioning.

- Lead times: depend on configuration, but most standard ultra fine powder mill systems ship in a few months; highly customized pharmaceutical jet mill lines may take longer.

- Customization options:

- Inline classifiers, multi-stage classifier mill system

- Skid-mounted or modular frames

- Stainless steel or high-nickel alloys for corrosive or ultra-pure products

- Full integration with upstream feeders and downstream dust-free powder processing and packing.

How Easy Is Cleaning, Maintenance, and Getting Spare Parts?

We engineer the air jet pulverizer for simple, repeatable cleaning and low downtime.

- Cleaning:

- Tool-free or quick-release access to the grinding chamber and classifier

- Options for clean-in-place jet mill systems with validated cleaning recipes

- Smooth internal surfaces and minimal dead zones for sanitary processing

- Maintenance:

- Wear parts designed for fast swap-out

- Online monitoring of pressure, temperature, and differential pressure

- Clear access to nozzles, classifier wheel, and filter elements

- Spare parts:

- Standardized components for the micron master pulverizer series

- Long-term parts support and recommended spare kits for global customers.

Do You Support Regulatory and Validation Needs for Pharmaceutical Jet Mills?

Yes. Our pharmaceutical jet mill solutions are built for regulated markets and high-purity APIs.

- Design & documentation:

- FDA compliant milling equipment design principles

- Full documentation set: IQ/OQ support, FAT/SAT protocols, material certificates, weld logs

- Process validation:

- Tight control over D50/D90 for pharmaceutical micronization

- Support for cleaning validation, cross-contamination risk analysis, and batch traceability

- Regulatory experience: we have delivered multiple pharmaceutical jet pulverizer particle size reduction lines, including complex pharmaceutical micronization projects, for clients in the US, EU, and Asia.

If you share your target material, capacity, and regulatory requirements, I can guide you to the exact jet pulverizer machine setup and scale that fits your plant and market.