The rise of porous carbon—especially silicon-carbon composites—is reshaping the future of high-performance battery anodes. But here’s the catch: achieving ultra-fine, contamination-free particle sizes with preserved pore structure is a huge challenge that traditional mills simply can’t overcome. That’s why the jet pulverizer, or fluidized bed jet mill, has become the go-to technology for processing these delicate, heat-sensitive materials. If you’re in battery manufacturing or R&D, understanding why a porous carbon jet pulverizer delivers unmatched particle size control, purity, and pore integrity is essential to staying competitive in 2025 and beyond. Let’s explore exactly why this advanced milling solution is rewriting the rules for next-gen battery materials.

What Is Porous Carbon and Why Is It So Difficult to Mill?

Porous carbon materials are essential components in modern battery technology, including silicon-carbon composites, resin-based carbons, biomass-derived carbons, coal-based carbons, and hard carbons. Each type plays a crucial role in enhancing battery performance—whether improving energy density, cycle life, or charge rates.

However, porous carbons present significant milling challenges due to their unique physical properties:

- High porosity and low density: This makes the material fragile and hard to handle without damaging its structure.

- Brittle yet abrasive nature: The particles break easily but can quickly wear down grinding equipment.

- Heat sensitivity: Excessive heat during milling leads to pore collapse and loss of surface area, critically impacting battery efficiency.

Conventional grinding methods, such as ball mills and rotary grinders, often turn into a nightmare when applied to porous carbon:

- Contamination risk: Metal wear debris contaminates carbon powders, degrading battery quality.

- Heat buildup: Inefficient cooling causes thermal damage, changing material properties.

- Wide particle size distribution (PSD): Results in inconsistent battery performance and clogged battery electrodes.

- Pore structure collapse: Aggressive mechanical forces destroy the very porosity that enhances capacity and ion diffusion.

In short, milling porous carbon demands precision, gentle handling, and stringent contamination control—criteria that traditional mills struggle to meet. This sets the stage for advanced jet pulverizer technologies tailored specifically for these sensitive materials.

Jet Pulverizer (Airflow Mill) Technology Explained

Jet pulverizers, also known as airflow mills, use high-velocity compressed air to grind porous carbon without any grinding media. This technology includes various designs such as the fluidized bed jet mill, spiral jet mill, and the advanced QLM series, each optimized for ultra-fine particle size control and preserving delicate pore structures.

How It Works

- Fluidized bed jet mill: Particles are suspended in an air stream, continuously colliding within a fluid-like zone for uniform, ultra-fine grinding.

- Spiral jet mill: Uses a strong spiral airflow that accelerates particles along a curved path, enabling high-impact collisions and efficient size reduction.

- QLM series: Combines precise airflow control and innovative classifier design to deliver stable milling with very narrow particle size distributions ideal for battery-grade porous carbon.

Key Components

- Classifier wheel: Separates particles by size, ensuring only those meeting strict size requirements exit the mill, critical for controlling D50 and D100.

- High-pressure nozzles: Inject compressed air at supersonic speeds, driving particle collisions without any mechanical contact.

- Expansion chamber: Allows the air to rapidly expand, cooling the mill internals and the product simultaneously.

Why Heat Generation Is Nearly Zero

The jet pulverizer’s adiabatic expansion cooling means that as compressed air expands inside the chamber, temperature drops instantly. This keeps the powder cool throughout milling, protecting heat-sensitive porous carbons from thermal degradation—a common problem in conventional grinding.

Contamination-Free Design

Jet pulverizers avoid metal-to-metal contact entirely, eliminating wear-related contamination. Internal surfaces are often lined with ceramic liners or other wear-resistant materials, further safeguarding product purity—essential for battery-grade materials like silicon-carbon anodes. This contamination-free setup is a major advantage over traditional ball mills or mechanical grinders.

For those interested in more details about classification and contamination controls in mills, exploring advanced air classifier mill porous carbon technologies provides valuable insights.

Why Jet Pulverizers Are the Industry Standard for Porous Carbon

Jet pulverizers shine in grinding porous carbon because they achieve ultra-fine particle sizes with ease—routinely hitting a D50 between 0.5 and 3 μm. This precision is crucial for battery-grade porous carbon, where particle size uniformity directly impacts performance. Thanks to their advanced air classifier design, these mills deliver an extremely narrow particle size distribution, often with a span less than 1.5, ensuring consistency batch after batch.

Controlling the D100 (the largest particles) is just as important. Jet pulverizers excel here by eliminating oversized particles that can cause short circuits in batteries, improving safety and reliability. At the same time, their gentle yet efficient airflow milling preserves the delicate pore structure and high specific surface area (BET) of porous carbon—key factors for energy storage capacity.

For air- and heat-sensitive materials like silicon-carbon composites, many jet pulverizers offer an oxygen-free processing option using a nitrogen inert gas loop. This protects the material from oxidation during milling. Plus, because jet mills don’t use grinding media, there’s zero risk of metallic contamination, which is critical when working with battery anode materials.

This contamination-free, finely controlled, and pore-preserving milling approach makes jet pulverizers the gold standard for porous carbon processing today.

For more on milling technology options and key features, check out our detailed guide on air classifier mills.

Real Performance Data and Case Studies (2024–2025)

Recent trials with porous carbon jet pulverizers clearly show their unmatched performance for battery materials. For silicon-carbon anodes, we’ve routinely achieved a D50 around 1.2 μm and kept D100 below 8 μm. This fine and tightly controlled particle size distribution translates to a 12% improvement in capacity retention compared to traditional ball-milled silicon-carbon – a significant boost in battery efficiency and lifespan.

When milling biomass-derived hard carbon, the jet mill preserves more than 95% of the original BET surface area, ensuring the porous structure remains intact and active. This is critical for maintaining electrode performance and charge capacity.

Coal-based porous carbon milled with airflow jet mills has also demonstrated superior consistency and particle size control, which is essential for next-gen sodium-ion battery development.

These real-world results confirm why jet pulverizer technology is fast becoming the industry go-to for ultra-fine, contamination-free processing of porous carbon materials. If you want to dive deeper into the milling principles behind these results, check out detailed insights on our air classifier mill porous carbon solutions.

How to Choose the Right Jet Pulverizer for Porous Carbon

Selecting the ideal porous carbon jet pulverizer requires a clear look at your production needs and technical specs. Here’s a straightforward guide to help you decide:

| Key Factors | Considerations |

|---|---|

| Production Scale | – Lab: 1–5 kg/h for R&D and small batches – Pilot: 30–100 kg/h for scale-up – Full Production: 500–2000 kg/h for mass manufacturing |

| Particle Size Control | Ensure the jet mill can fine-tune classifier speed and airflow to hit your target D50 and D100 values precisely |

| Classifier Speed & Airflow | – Higher classifier speeds help exclude oversized particles – Optimized airflow improves milling efficiency and PSD (particle size distribution) narrowness |

| Internal Lining Material | – Ceramic liners: Best for zero contamination and longer wear life – Stainless steel: More cost-effective but risk slight metallic contamination |

| Inert Gas System | – Essential for air-sensitive porous carbon like silicon-carbon composites – Nitrogen or argon loops prevent oxidation and pore structure damage |

Remember, fine control of classification and internal materials directly impacts your final product quality, especially when grinding ultra-fine porous carbons. For smoother classification and separation, check out advanced air classifier mill designs tailored to battery materials.

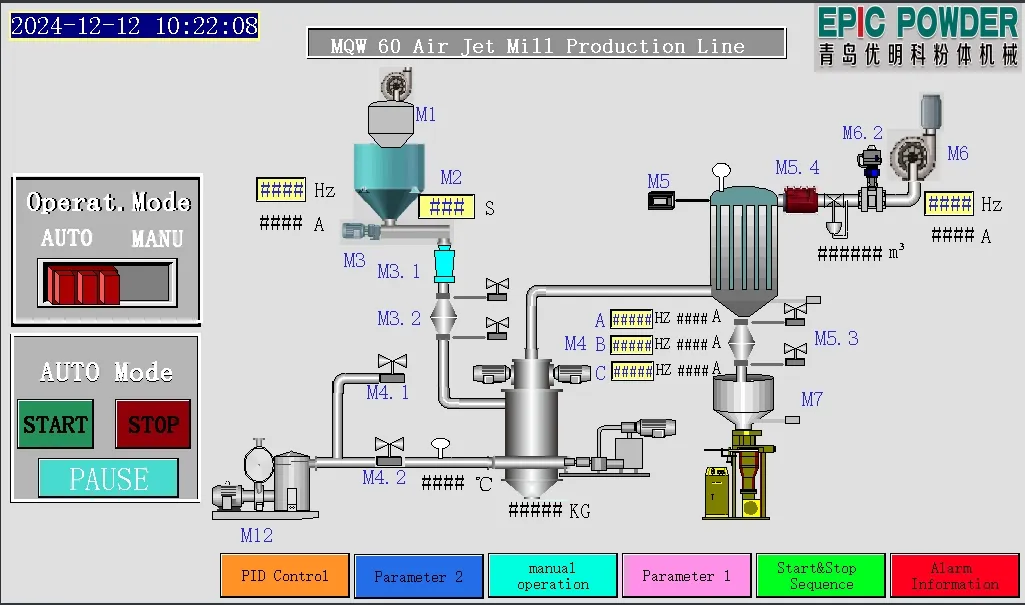

EPIC Powder Machinery – The Specialist You Need

With over 15 years dedicated to battery material jet milling, EPIC Powder Machinery stands out as a trusted partner for processing porous carbon. Their QLM series is specially optimized for handling challenging materials like porous carbon and silicon-carbon anodes, ensuring precise particle size control and pore structure preservation.

EPIC offers turnkey solutions covering every step—from feeding and milling to classification, dust collection, and inert gas protection systems—designed to meet the strict requirements of battery-grade porous carbon processing. Their global installations demonstrate proven performance, backed by reliable 7×24 after-sales support to keep your production running smoothly.

For those needing expert guidance on airflow mill selection or customization, EPIC Powder Machinery is a reliable choice with a deep industry focus on contamination-free milling and ultra-fine grinding of battery materials.

FAQs on Porous Carbon Jet Pulverizers

Can a jet mill really reach D50 below 1 micron for porous carbon?

Yes, advanced porous carbon jet mills routinely achieve D50 values below 1 micron. The design of fluidized bed and spiral jet mills provides intense particle collisions and precise classification, allowing ultra-fine grinding without damaging the delicate pore structure.

What is the difference between spiral jet mill and fluidized bed jet mill for this application?

Spiral jet mills use high-speed spiraling airflow to grind particles mainly by particle-to-particle impact, ideal for consistent narrow PSD and dry, delicate materials.

Fluidized bed jet mills operate by suspending particles in an upward airflow, generating a high-velocity particle bed for superfine grinding. They excel in achieving very fine, uniform particle sizes with minimal heat generation.How to avoid pore collapse during superfine grinding?Use jet pulverizers with adiabatic expansion cooling to prevent heat damage.

Maintain low energy density grinding conditions and avoid overgrinding oversized batches.

Employ protective inert gas atmospheres to preserve sensitive pore structures during milling.Is oxygen control necessary when milling silicon-carbon composites?

Yes, oxygen-free or inert gas jet milling is recommended for silicon-carbon anodes to prevent oxidation, which can degrade performance. Nitrogen inert gas loops keep the process environment stable and contamination-free.

Typical ROI timeline when switching from ball mill to jet mill

Most companies see a return on investment within 6 to 18 months. This comes from improved product quality, higher yield due to narrow particle size distribution, reduced contamination, and lower maintenance costs, especially when processing sensitive porous carbon materials.

For a deeper understanding of jet mill technology for battery materials, you might find our article on which materials are most suitable for grinding using a jet mill pulverizers helpful.